Machine vision software is a cornerstone of modern manufacturing, logistics, and quality inspection. With numerous platforms available — each offering distinct strengths and drawbacks — choosing the right system can be challenging.

This article compares Basler vs Keyence, and EasyODM —three machine vision providers with unique capabilities. Below, we delve into the specifics of each platform to help you decide which aligns best with your needs.

Key Comparison Factors

| Aspect | EasyODM | Basler | Keyence |

|---|---|---|---|

| Cost-Effectiveness for Small and Medium Enterprises | +++ | ++ | ++ |

| Versatility in 2D and 3D Vision | ++ | +++ | +++ |

| Ease of Use | +++ | ++ | ++ |

| Brand Recognition | + | ++ | ++ |

| Setup Simplicity | +++ | ++ | ++ |

| Software Ecosystem Flexibility | +++ | ++ | + |

| Environmental Suitability | ++ | +++ | ++ |

Basler VS Keyence VS EasyODM

Now, let’s dive deeper into the pros and cons of each of these machine vision systems. This comparison breaks down the main benefits and challenges of each platform, helping you choose what works best for your business.

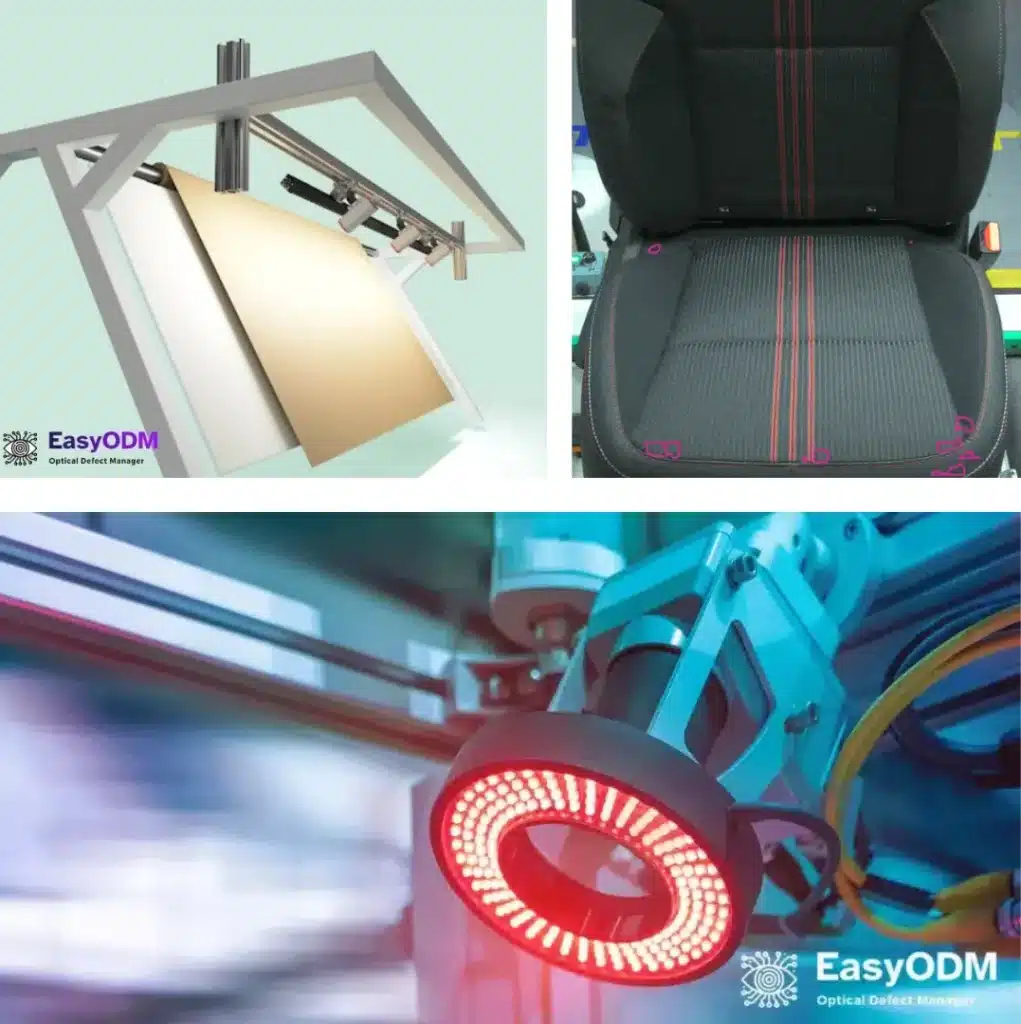

EasyODM

At EasyODM, we provide highly flexible and cost-effective machine vision solutions, suitable for all types of businesses, from small to medium-sized and beyond. Our platform offers robust integration options that ensure seamless compatibility across various hardware and platforms, making us a reliable choice for businesses in need of scalable, customized solutions.

Pros:

- Flexible Hardware Integration: EasyODM’s open platform allows users to select the most suitable hardware, including cameras and sensors, tailored to specific requirements. It supports smooth integration with various hardware types, including digital I/O modules like BrainBox, ensuring compatibility across diverse industrial setups. This flexibility allows for efficient integration with existing systems, creating a tailored and scalable solution.

- Cost-Effective Vision Solutions: EasyODM delivers budget-friendly machine vision capabilities without additional licensing requirements. This approach makes it an accessible option for businesses looking to implement vision solutions without incurring excessive costs.

- Open AI Ecosystem: EasyODM supports deploying models from popular deep learning frameworks, offering the flexibility to leverage advanced AI for custom applications. This open approach allows companies to use existing AI models or create new ones tailored to specific inspection tasks.

- Graphical Programming for Customization: Users can create custom algorithms using graphical function blocks and control tabs, enabling development without the need for coding. This makes it possible for users without programming skills to develop and modify solutions, enhancing ease of use and flexibility.

- Scalable System Design: EasyODM is built to scale effectively, allowing small businesses to start with essential capabilities and expand as operational demands grow. This scalability makes it easy for growing companies to add new features without requiring a complete system overhaul.

- Efficient Deployment Process: EasyODM emphasizes a quick setup and deployment approach. With pre-configured workflows and a modular design, users can get their systems up and running in less time, minimizing operational disruptions and allowing companies to begin benefiting from automation sooner.

- Tailored Solutions for Specific Industry Needs: EasyODM excels at delivering customized solutions that meet unique business demands. The flexibility of the system makes it suitable for highly specialized applications across different sectors, addressing specific challenges faced by each industry.

Cons:

- Focused Mainly on 2D Vision: We currently focus on 2D vision tasks that work well for most manufacturing needs. However, as demand for 3D inspection grows, we’re actively developing our own 3D vision solutions to meet those future needs.

- Growing Presence in the Market: As a new player in the machine vision industry, we’re dedicated to building our brand and establishing a strong presence. Although some businesses may be more accustomed to legacy platforms like Basler vs Keyence, we are consistently gaining trust thanks to successful implementations and positive feedback from our customers.

- Expanding community and Resources: Our user community is still fairly new, but it’s growing as more businesses start using our solutions. We’re focused on supporting this growth by engaging with users and creating useful resources like forums and support channels.

Basler

Basler Machine Vision provides reliable imaging capabilities and flexible camera options, making it applicable for various industrial uses. It emphasizes durable hardware that delivers strong performance in challenging environments, generally requiring minimal maintenance.

Pros:

- Reliable Imaging and Camera Flexibility: Basler’s camera lineup supports a variety of imaging needs, from high-resolution models to compact designs suited for smaller spaces. The quality control on each camera ensures reliable imaging performance for logistics, manufacturing, and inspection tasks.

- Durable Design for Industrial Use: Basler cameras are designed to handle harsh environments with IP67-rated enclosures, offering resistance to dust and moisture. This durability makes them a good fit for demanding industrial applications, though it may exceed the needs of simpler environments.

- Basic Software Setup: The Basler pylon Camera Software Suite allows for relatively easy setup, with support for multiple programming languages. In complex environments, skilled teams can leverage its flexibility for smooth integration.

- Efficient Multi-Camera Setup: Basler’s multi-camera synchronization feature can manage up to seven cameras working over distances up to 100 meters, providing extensive coverage for large-scale logistics or warehouse applications. The setup is efficient, though managing multiple cameras can add a layer of operational complexity.

Cons:

- Inconsistent Support for Older Product Versions: Support for legacy products can be inconsistent, potentially making it harder for customers that are using older Basler products to maintain or upgrade their systems efficiently.

- Limited Integration Beyond Basler Ecosystem: Basler’s hardware and software are primarily optimized for use within their ecosystem, which could possibly present compatibility challenges when integrating non-Basler components.

- Complex Software Interface: Basler’s software, while feature-rich, might potentially present a learning curve for new users, potentially requiring some additional training to use effectively.

Keyence

Keyence Machine Vision is known for its AI-driven features and multi-spectrum imaging capabilities, which support detailed visual inspection. It is used in industries needing adaptable imaging and precision, providing reliable performance across various conditions.

Pros:

- Multi-Spectrum Imaging for Color Differentiation: Keyence’s CV-X and XG-X series use multi-spectrum lighting to distinguish subtle color differences, which can be helpful for sorting and inspecting similar materials, such as plastics.

- 3D Pattern Projection Inspection: Keyence’s 3D vision systems capture both height and profile data in real-time, which can be useful for inspecting more complex components like solder joints and adhesive applications.

- Rugged Design for Industrial Environments: Keyence models, such as the SR-750 code readers, are IP65/IP67-rated, offering resistance to dust and moisture. Their compact design can also facilitate integration into tighter spaces.

- Efficient Multi-Unit Networking: Keyence devices support Power over Ethernet (PoE) and multi-drop link, enabling operation as a unified system with up to 32 units. This setup could reduce complexity in power and connectivity management, with some coordination needed to fine-tune for optimal results.

Cons:

- Price vs. Precision Trade-off: While Keyence offers great accuracy, the system may require longer processing times for precise inspections, as noted in this Keyence Vision System product review. Moreover, it was mentioned that Keyence system’s cost could be substantial, and buying it is the correct option if you need very precise readings. Meaning it might not be justifiable for applications that don’t require extreme precision, potentially making the system less cost-effective for general inspection tasks.

- Downtime Risk from Proprietary and Discontinued Parts: Keyence’s use of proprietary parts means replacements generally need to be sourced directly from them. Once a product reaches its end-of-life, replacement parts can be difficult to find, causing potential downtime, particularly for older models with limited support. You can read about one such instance here.

- Complex System Updates: Updating firmware or adding new functionalities to Keyence products could potentially be a complex process that requires specialized technical skills, leading to longer update cycles.

Choosing the right solution

By focusing on what matters most to your business — whether it’s comprehensive industrial support, precision quality control, or budget-friendly, adaptable solutions — you can make an informed choice that aligns with your goals and resources. Each system offers unique strengths to meet a range of operational needs and integration requirements.

EasyODM is a compelling choice when it comes to balancing cost, precision, complexity, and integration needs. We offer flexible solutions tailored for businesses of all sizes, especially small to mid-sized companies. With the ability to grow alongside your business and adapt to existing systems without significant re-investment, EasyODM stands out as an attractive solution for modern industrial applications.

We’re also expanding into 3D vision to meet growing market demands. In the meantime, we remain committed to providing strong support to ensure your needs are fully met, both during and after implementation.

Basler could be a solid choice for companies prioritizing high-quality imaging with durable hardware, it’s well-suited for standard inspection and logistics applications. Its range of camera options is versatile, adapting to different industrial needs and offering straightforward setup, even in challenging conditions. Although compatibility issues could arise because of its limited use outside their ecosystem.

Keyence offers AI-driven tools and multi-spectrum imaging, making it a good choice for inspections needing precision and adaptability. However again, reliance on proprietary parts can pose some challenges, as replacements may be harder to find if components are discontinued, potentially leading to downtime, particularly with older models with limited support options.