How AI Quality Control Works

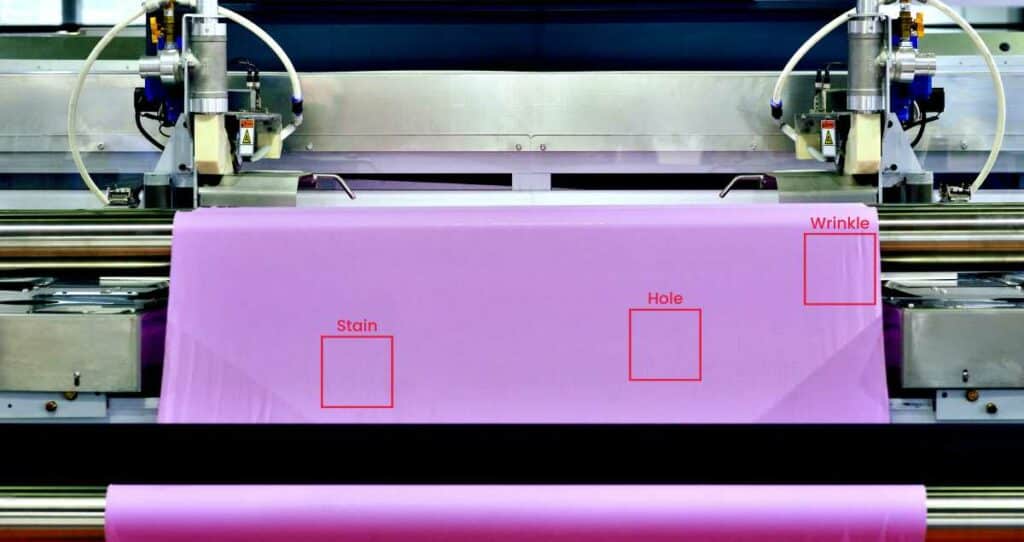

Leverage the power of EasyODM in the textile industry to streamline your quality control processes. Our seamless software integration and advanced techniques enable precise defect detection, ensuring enhanced textile quality and operational efficiency.

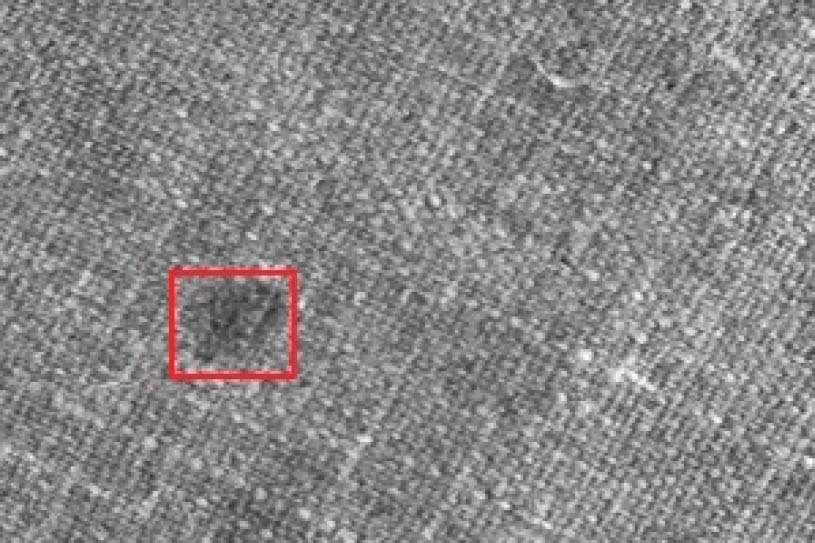

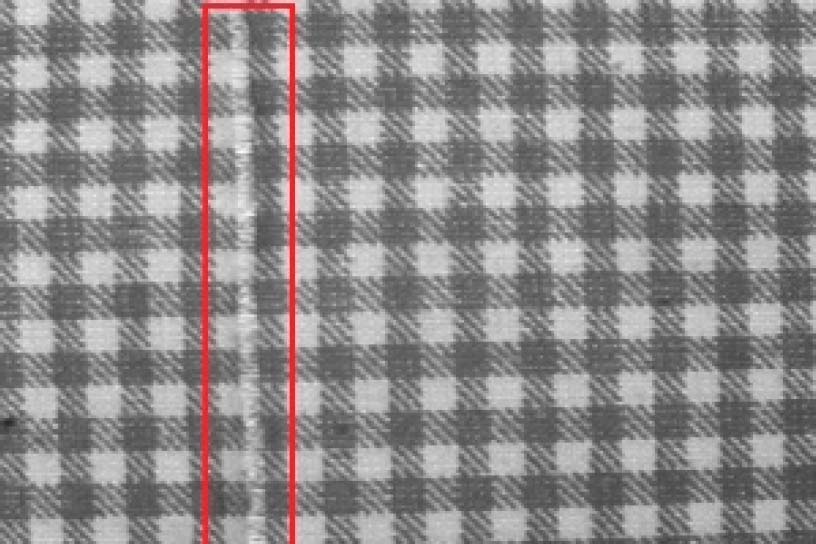

AI-Driven Defect Detection Use Cases in Textile Industry

Explore the wide range of defects that can be detected and pinpointed in textile surfaces, including stains, tears, holes, knots, snags, pilling, uneven dyeing, misprints, fading, skewing, shrinkage, seam slippage, wrinkles, and more.

Advantages of EasyODM for the Textile Industry

Unlock the Unmatched Benefits of easyODM Automated Visual Inspection Software.

Business Development Manager