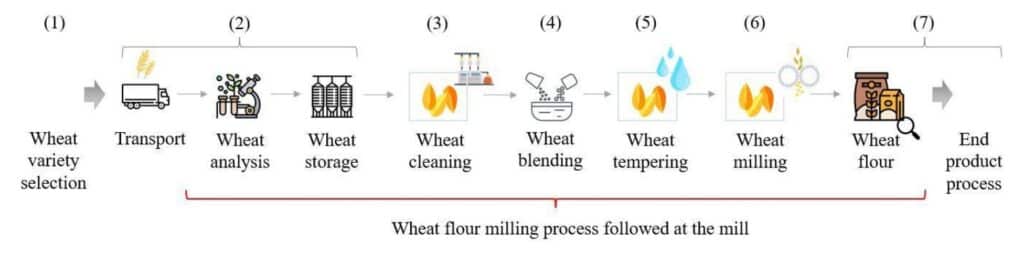

Artificial Intelligence (AI) is changing many industries, including flour milling. It makes processes faster, improves the quality of flour, and reduces costs. In flour mills, AI enhances every step, from grain reception to final product packaging.

These advancements are helping mills meet high consumer demand while maintaining top-quality standards. This article explains how AI is transforming flour mills and helping both producers and consumers.

Key Takeaways

- Improved Grain Reception: AI speeds up grain sample analysis, making it 30 times faster than traditional methods. This helps ensure only high-quality grains are used.

- Enhanced Milling Operations: AI makes real-time adjustments to the milling process. This helps maintain consistent particle sizes and improves efficiency.

- Better Quality Assurance: AI monitors flour production in real time, making sure the final product meets specific customer needs and high-quality standards.

- Optimized Grain Blends: AI reduces the trial-and-error process in blending grains. This improves flour yield and ensures the final product meets market demands.

- Regulatory Compliance: AI helps flour mills follow safety and quality rules. It does this by monitoring processes and keeping accurate records.

- Predictive Maintenance: AI-supported predictive maintenance can increase productivity by 25%. It also extends equipment lifespan by 20% and reduces downtime by up to 50%.

- Energy Savings: AI can also help in optimize energy use. A survey found that 36% of companies saw increased energy savings from using AI.

Better Grain Reception

AI is making the grain reception process more efficient in flour mills. Advanced AI systems can sort and grade incoming grain automatically. This ensures that only the best grains are used.

EasyODM’s grain sample analysis technology checks grain samples 30 times faster than traditional methods. By doing this, AI helps keep flour quality, consistency and reduces mistakes. Using AI in this way allows flour mills to handle larger volumes of grain more efficiently.

Improving Milling Operations

AI also plays a key role in milling operations after grain is received. Studies show that 75% of flour quality depends on the quality of the wheat. The other 25% depends on the milling technology and conditions in the mill. AI helps improve both by selecting high-quality grain and optimizing milling parameters.

AI’s key benefits for milling operations:

- Real-time adjustments: AI monitors the grinding process and makes real-time adjustments to ensure uniform particle size.

- Meeting customer needs: By keeping particle sizes uniform, AI helps flour mills meet specific customer requirements.

- Boosting efficiency: AI optimizes the milling process, resulting in better use of resources and less waste.

By adopting AI, flour mills can ensure they meet high standards consistently, giving them a competitive edge.

Better Quality Assurance

AI not only maintains the mill’s reputation but also improves it. It does this by consistently delivering high-quality flour that meets customer demands. Flour mills that adopt AI for quality assurance are more likely to gain customer trust and expand their market share.

AI greatly improves flour quality throughout the entire production process. It checks different parameters during the milling process. This is important for meeting specific needs. For example, bakeries often require flour with specific characteristics.

AI provides consistent results, ensuring that the end product is of high quality. Unlike traditional methods, where changes were hard to make during production, AI allows for real-time corrections. This reduces mistakes and ensures the final product meets customer expectations.

Optimizing Grain Blends

Blending different types of wheat is important for making high-quality flour. Traditionally, finding the right blend took a lot of trial and error. AI has made this process more accurate.

- Data-based determination: AI systems can now determine the best blend ratios for different types of wheat.

- Wanted flour qualities: This ensures the flour has the desired texture, density, and other qualities.

- Flour yield improvements: Using AI not only reduces guesswork but also improves overall flour yield.

It optimizes the final product to meet the specific needs of the mill’s customers. Flour mills benefit from these optimized blends. They can produce consistent products that satisfy market demands.

Ensuring Compliance with Regulations

Following food safety and quality regulations is very important for flour mills. AI can help with this. AI systems can monitor each stage of the milling process.

Simplifying audits

They can also keep records automatically, ensuring that all regulations are met. This makes it easier for mills to stay compliant with regulations like the Food Safety Modernization Act (FSMA).

AI captures and stores important data. It also simplifies audits and reduces the risk of non-compliance. Flour mills that use AI for regulatory compliance are better positioned to avoid fines, recalls.

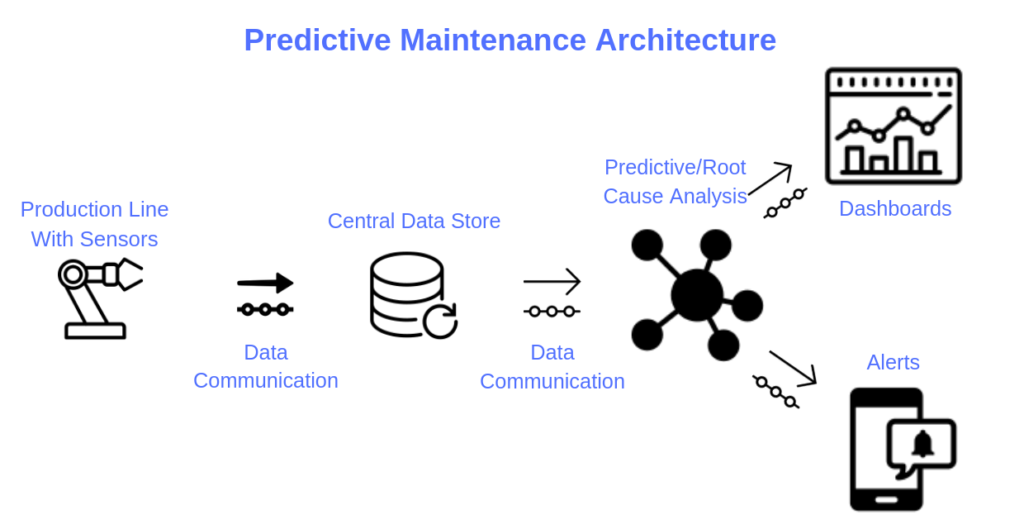

Predictive Maintenance and Equipment Optimization

AI is also changing how maintenance is done in flour mills. Predictive maintenance helps keep equipment running efficiently and avoids unexpected failures. Here are some key benefits of predictive maintenance supported by AI:

- Productivity boost: Predictive maintenance can increase productivity by 25% on average.

- Downtime reduction: Predictive maintenance can cut equipment downtime by up to 50%.

- Cost savings: Overall maintenance costs can be reduced by 5-10% due to AI’s ability to predict and prevent issues.

- Extended equipment lifespan: Regular monitoring and timely maintenance can extend equipment lifetime by 20%.

These benefits make AI-driven predictive maintenance a valuable tool. It helps flour mills to reduce costs and stay competitive in the market.

Saving Energy

Through predictive maintenance, AI also helps in optimizing overall operating time and energy consumption. This is important for reducing production costs and increasing profitability. By using AI, mills can reduce operating time and improve energy efficiency. These strategies can significantly cut energy consumption.

Companies who already implemented predictive maintenance

A survey found that 36% of respondent companies reported increases in energy savings due to predictive maintenance. Based on this survey, it’s fair to say that it will lead to cost savings and higher profits for the milling operations. Flour mills that implement these AI-driven strategies find that their operating costs decrease. This makes them more competitive in the market.

AI in the Future of Flour Milling

AI technology continues to evolve. It is expected to play an even bigger role in flour milling in the future. New technologies, like advanced robotics and machine learning, promise greater efficiencies.

AI-driven supply chain management can improve the traceability of grain from farm to mill. This ensures transparency and accountability. Predictive analytics will become more advanced, allowing for more precise milling operations.

By adopting these advancements, flour mills can increase productivity. They can also reduce costs and deliver better products.

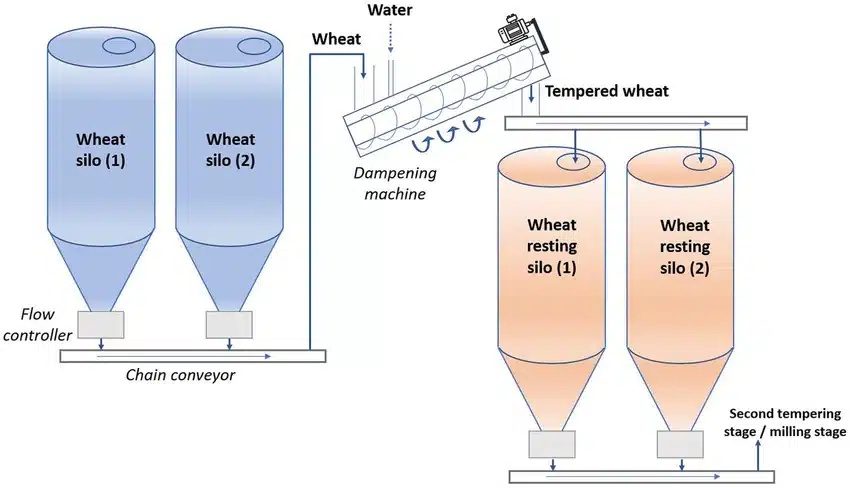

Improving Grain Tempering with AI

AI is expected to improve grain tempering in the future. Tempering affects flour yield and quality. It changes the size of bran and endosperm particles, which are key to flour quality. Right now, optimizing tempering levels is complex.

It depends on factors like environmental conditions and grain quality. AI could help by adjusting tempering settings in real-time.

This could improve flour quality and yield. Future research and development in AI could could unlock these possibilities. This would allow better control over the tempering process and consistent product quality.

(Source)

Conclusion

AI is transforming the flour milling industry. It offers many benefits, such as better efficiency, improved quality, and reduced costs. From better grain reception to optimizing milling operations, AI is a game-changer.

As flour mills continue to adopt AI, they will not only improve their products but also gain a competitive advantage. The future of flour milling lies in using AI to meet changing market demands and ensure a strong, sustainable industry.