In today’s fast-paced industries, packaging plays a key role. Packaging must be sturdy. It must keep the product safe from production to the consumer. Weak packaging can cause issues. It can lead to product spoilage.

It can cause contamination or customer complaints. Packaging Integrity Inspection with AI is changing how companies handle quality assurance. It provides efficient, accurate, and consistent inspections.

Key Takeaways:

- AI and Blockchain Integration: Blockchain provides traceability while AI enhances inspection accuracy. Packaging integrity inspection with AI and blockchain together are able to bring packaging integrity inspection to new heights.

- Improved Label Accuracy: AI helps prevent mislabeling, therefore enhancing packaging reliability.

- Food Freshness Monitoring: Intelligent packaging with sensors helps detect gas levels. This ensures food stays fresh longer.

- Scalability in Inspections: AI scales easily for different production levels. It maintains high accuracy for both small and large batches.

- Anti-Tampering Technologies: Intelligent packaging includes features like holograms. These detect unauthorized opening or tampering.

What is Packaging Integrity Inspection?

Packaging Integrity Inspection makes sure that a product’s packaging is intact. It checks for flaws or weaknesses. Packaging must protect its contents effectively. Any cracks, leaks, or faults could risk product quality.

Traditionally, this inspection was manual. Workers checked each item. But manual inspections have limitations. Human error, fatigue, and inconsistency impact results. This is where AI steps in.

How Packaging Inspection with AI Differs

Packaging Integrity Inspection with AI uses machine vision software and deep learning. AI-powered cameras detect small defects. These defects may be invisible to the human eye. The AI system captures images of the packaging. It then analyzes these images in real time. It looks for flaws that might compromise the package. The difference here is that AI inspection is fast, and also highly accurate.

AI systems continuously learn and improve. They can handle complex inspection tasks. AI also works without fatigue. It does not suffer from common human issues. This improves quality control. It reduces the chances of a faulty product reaching the consumer. Packaging Integrity Inspection with AI ensures better quality.

Examples of Packaging Defects Detected by AI

AI can detect many packaging defects. Some common examples include:

- Seal Leaks: Packages with improper seals.

- Tears and Punctures: Damaged areas in the packaging film.

- Label Misplacement: Incorrect positioning of labels.

- Incorrect Fill Levels: Products that are under or overfilled.

These defects are critical. Packaging Integrity Inspection with AI ensures these defects are addressed before the product reaches the consumer, providing a vital layer of quality control. If unnoticed, they can lead to quality issues. Packaging Integrity Inspection with AI ensures all products meet quality standards.

Blockchain and AI in Packaging Integrity

Blockchain and AI enhance Packaging Integrity Inspection, allowing manufacturers to benefit from both technologies working together seamlessly. Packaging integrity inspection with AI and blockchain ensures traceability and transparency. Blockchain acts as an immutable ledger. It tracks each product’s journey.

AI detects defects through precise data analysis. This adds strong quality assurance. Together, these technologies solve many packaging issues. Intelligent packaging with blockchain and AI reduces tampering and fraud. It helps manufacturers maintain consumer trust. It ensures product safety throughout the supply chain.

AI Technology in Use

Packaging integrity inspection with AI involves machine learning models. These models distinguish between a good package and a faulty one. Machine vision is one of the core technologies. Cameras installed on production lines feed visual data to AI systems. The AI then analyzes this data in milliseconds.

Custom packaging

AI can also adapt to various custom packaging needs. Different products require unique packaging specifications, and AI systems can be tailored to meet these demands. This adaptability ensures that diverse products, whether delicate or robust, are inspected to the same high standards, maintaining consistency in quality control.

Food freshness detection

AI-powered intelligent packaging can also enhance food freshness detection. This is done through real-time monitoring. Sensors in the packaging measure oxygen, carbon dioxide, as well as other things. These gases indicate freshness. This helps producers maintain product quality throughout the supply chain.

AI Makes Inspections Scalable

One big advantage of AI in Packaging Integrity Inspection is scalability. As production grows, so does the need for fast inspections. AI-based systems can handle high volumes without losing accuracy. Whether it is a small batch or a large production run, AI delivers consistent results.

Intelligent Packaging for Anti-Tampering and Traceability

Intelligent packaging technologies are crucial. They maintain the integrity of packaged goods. Features like anti-tampering holograms and photonic crystals show if the packaging has been opened. These technologies pair with AI to provide extra security. AI-enabled intelligent packaging prevents tampering. It monitors conditions and detects unauthorized access.

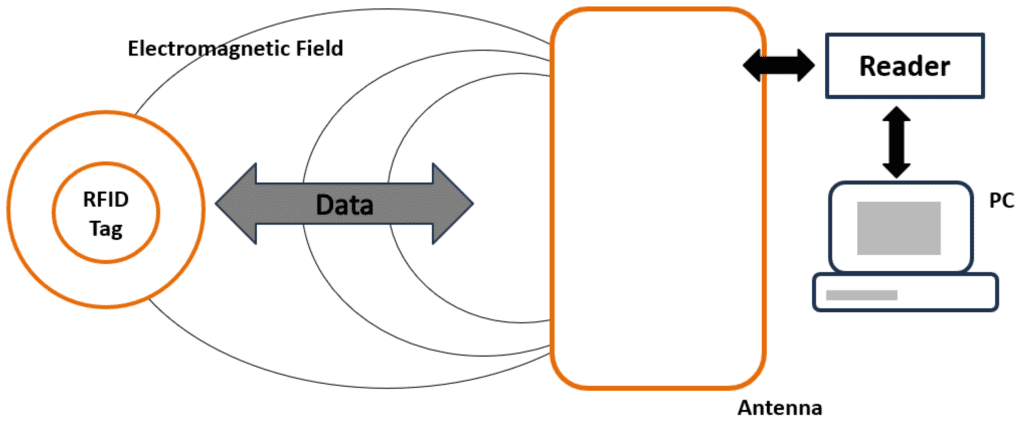

Traceability is another key feature of intelligent packaging. Technologies like RFID tags, QR codes, and sensors track products through every stage of the supply chain. AI analyzes data from these technologies. It ensures packaging integrity. It prevents issues like mislabeling or counterfeit products.

Challenges of Implementing Packaging integrity Inspection with AI

While there are many benefits, there are also challenges. Implementing AI in Packaging Integrity Inspection can be costly. Setting up AI-powered machinery and software needs investment. Training is also needed. Employees must know how to use AI systems. Technical issues can also arise. AI systems need regular updates and maintenance.

Ensuring data security and privacy is crucial too. With AI and blockchain integration, companies must protect sensitive information. A decentralized blockchain network helps with data security, but challenges with costs and technical complexities remain.

The Future of Packaging Integrity Inspection

The future of Packaging Integrity Inspection with AI looks promising. As it continues to evolve, the potential for achieving higher accuracy and efficiency grows. AI and IoT (Internet of Things) are already integrated, enhancing data collection and analysis.

In the future, their integration will be even more seamless, leading to better insights and automation. Packaging integrity inspection with AI, with the help of robotics, will also bring more advanced automated systems, needing less human intervention and resulting in a smoother process.

Intelligent packaging technology is evolving. It includes real-time, non-invasive monitoring that is cost-effective. Fluorescent probes detect gas changes, making food freshness inspection better. These technologies improve quality control. In the future, intelligent packaging will integrate more with AI, providing better predictive analytics and adaptive responses.

This will make freshness detection more accurate and efficient. These advancements will also extend shelf life and optimize packaging for different products, boosting both efficiency and sustainability

Conclusion

Packaging Integrity Inspection with AI is changing packaging’s quality assurance. AI improves accuracy, efficiency, and consistency in inspections. Detecting defects early helps companies avoid recalls.

It ensures products reach customers in perfect condition, and also maintains high quality standards. As AI evolves further, it’s role in guaranteeing packaging integrity is going to become even more apparent.