Picture this: a bustling textile manufacturing factory, filled with machines whirring and workers rushing to keep up with production demands. But something is different here.

As we walk through the factory floor, we notice that there are no workers inspecting every single piece of fabric that comes off the machines. Instead, we see cameras and sensors monitoring the process, while a powerful AI system analyzes the data in real-time.

This is the future of textile production, where AI-driven quality control is revolutionizing the way we manufacture fabrics. By using machine learning algorithms to detect defects and inconsistencies in the production process, we can now optimize our manufacturing processes to produce high-quality textiles at a faster rate than ever before.

In this article, we’ll explore how AI is changing the textile industry, from smart fabric innovations to automated quality control, and what the future holds for this exciting new technology.

Key Takeaways

- AI-powered quality control systems detect defects and inconsistencies in real-time, improving efficiency and accuracy in production processes.

- Smart manufacturing allows for predictive maintenance, reducing downtime and increasing productivity.

- AI analyzes data to identify patterns and areas for improvement, optimizing production processes and reducing costs.

- AI-driven quality control achieves consistent and accurate quality control, reducing waste and improving efficiency, giving companies a competitive edge in the textile industry.

Brief overview of the textile industry

You might not realize it, but every time you put on a piece of clothing, it has likely gone through a complex process in the textile industry. Various materials are transformed into finished products through weaving, knitting, dyeing, and finishing.

The textile industry is a massive sector that contributes significantly to the global economy. It employs millions of people worldwide and provides us with the fabrics and materials we need for our daily lives. However, the production process in the textile industry is not without its challenges.

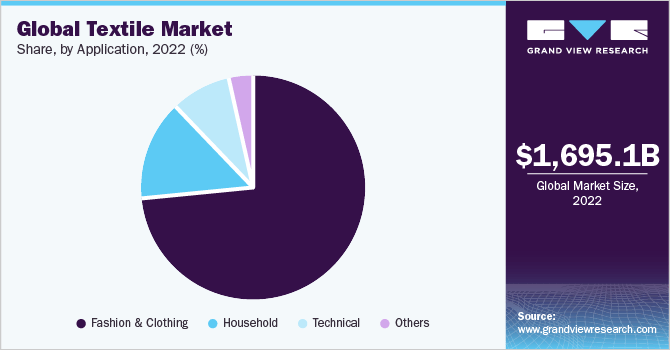

According to a report by Grand View Research, the global textile market size was valued at USD 993.6 billion in 2021 and is anticipated to grow at a compound annual growth rate (CAGR) of 4.0% from 2022 to 2030.

The U.S. is one of the largest markets for textiles, with shipments totaling USD 65.8 billion in 2022. India is the second largest producer of textiles in the world after China, with a market value of 223 billion U.S. dollars in 2021.

One of the biggest issues is quality control, which can be time-consuming and expensive. This is where artificial intelligence (AI) comes into play. By using AI-driven quality control, textile manufacturers can automate the process and ensure that the finished products meet the required standards.

AI in Textile Manufacturing

AI is revolutionizing the textile manufacturing industry by improving efficiency and accuracy in production processes. With the integration of artificial intelligence into smart manufacturing, textile production has become more streamlined and less prone to errors.

Design Innovation and Development

AI has revolutionized the textile manufacturing sector by transforming product design and development processes.

With its ability to analyze vast amounts of data and learn from patterns, AI algorithms assist designers in creating unique and appealing textile patterns, textures, and colors.

By leveraging machine learning algorithms and analyzing databases of existing designs, trends, and customer preferences, AI expedites the design process and ensures that the products align with market demands.

Optimizing Production Processes

AI-powered systems have significantly enhanced efficiency and quality control in textile manufacturing processes.

Through machine vision technology, AI algorithms analyze images of fabrics, identifying defects, irregularities, and classifying textile materials based on their properties.

According to a report by Fashinza, with the use of AI and new-age technologies, we can expect a reduction in wastage by about 60 to 70% as the processes will be automated with the highest possible accuracy. Industrial waste makes up at least 50% of global waste.

Much of that waste is the result of poor quality products from manufacturing processes. According We Forum AI can help workers reduce waste and lower the cost of quality.

This automation of quality control processes enables manufacturers to detect faults early on, minimize production waste, and improve overall yield. Integrating AI into production lines leads to reduced costs associated with faulty or substandard products.

Our machine vision software EasyODM detects 99% of wrinkle defects, ensuring flawless and high-quality fabrics. Dive into our detailed case study to learn how integrating AI into production processes optimized efficiency and quality.

Streamlining Supply Chain Management

AI plays a crucial role in optimizing supply chain management in textile manufacturing.

By analyzing historical data, market trends, and external factors, such as weather conditions, AI algorithms accurately predict demand, optimize inventory levels, and recommend supply chain strategies.

This helps manufacturers minimize stockouts, reduce excess inventory, and streamline production schedules. The integration of AI in supply chain management improves customer satisfaction and profitability.

Energy Efficiency and Resource Management

AI is instrumental in optimizing energy consumption and resource management in textile manufacturing.

By leveraging real-time data from sensors and IoT devices, AI algorithms monitor and control energy usage, identify areas of inefficiency, and suggest ways to optimize energy consumption.

This not only reduces operating costs but also promotes a more sustainable and environmentally friendly approach to textile manufacturing.

Enhancing Customer Service with AI Assistants

AI-powered chatbots and virtual assistants have transformed customer service in the textile industry.

These virtual assistants interact with customers, answer inquiries, provide product recommendations, and assist with online purchases.

By utilizing natural language processing and machine learning capabilities, AI chatbots offer personalized customer support around the clock, leading to improved customer satisfaction and increased sales.

Automated Quality Control

In the past, quality control relied heavily on human visual inspection, but this approach had its limitations. Humans can easily miss subtle defects or become fatigued over time, leading to inconsistencies in the inspection process. That’s where AI and machine learning step in, revolutionizing the textile industry.

By leveraging advanced algorithms and machine vision technology, AI-driven quality control systems can meticulously analyze every inch of fabric.

These intelligent systems can detect even the tiniest defects, such as misaligned patterns, loose threads, or discolorations. They work tirelessly, ensuring that every garment meets the strictest quality standards.

Let’s take the example of a automotive seats manufacturer that partnered with EasyODM to enhance their quality control processes. By implementing our AI-powered solution, they experienced a significant reduction in production defects and ROI increase. The system quickly identified and flagged any imperfections, allowing the manufacturer to take immediate corrective actions (click here to read the case study).

Not only does AI-driven quality control improve the overall product quality, but it also streamlines the production process. By detecting and resolving issues in real-time, manufacturers can prevent the accumulation of faulty products, reducing waste and saving valuable resources.

This technology has had a profound impact on both manufacturers and consumers. Manufacturers can now produce high-quality textiles at a faster pace, meeting market demands with precision. Consumers, on the other hand, can trust that the garments they purchase have undergone rigorous quality checks, ensuring their satisfaction and confidence in the brand.

AI-driven quality control has become a game-changer in the textile industry, transforming the way manufacturers approach quality assurance. With EasyODM’s expertise in machine vision and automation, we continue to empower textile manufacturers worldwide, enabling them to deliver impeccable products that stand out in the market.

Future of AI in Fashion Industry

The fashion industry is on the cusp of a technological revolution, and advancements in artificial intelligence are set to transform every aspect of the industry.

One example of how machine learning is being integrated into fashion manufacturing is AI-driven quality control in textile production. With AI, fashion manufacturers can achieve consistent and accurate quality control, reducing waste and improving efficiency.

It can also help them with forecasting trends and optimizing supply chains. According to report, in the next three to five years, generative AI could add $150 billion, conservatively, and up to $275 billion to the apparel, fashion, and luxury sectors’ operating profits.

The future of AI in the textile industry and specially fashion is bright, with the potential to revolutionize everything from design to production. As the technology continues to improve and become more accessible, we can expect to see more and more fashion companies adopting AI-driven solutions.

From predicting trends to optimizing supply chains, AI has the potential to transform the fashion industry for years to come.

Frequently Asked Questions

Conclusion

Overall, the integration of AI in textile production has shown promising results in terms of improving efficiency, reducing waste, and enhancing product quality. With the use of smart fabric innovations and automated quality control systems, manufacturers can optimize their production processes and ensure that their products meet industry standards.

As the fashion industry continues to evolve and demand for sustainable and ethical practices increases, the future of AI in textile manufacturing looks promising. With the ability to analyze data, predict trends, and optimize operations, AI can help manufacturers stay competitive and meet the needs of consumers.

It’s clear that the integration of AI in textile production isn’t just a trend, but a necessity for the industry to stay relevant and thrive in the years to come.