Optimize Your Plastic Production

Book a FREE consultation to see how AI fine-tunes your production process, enhancing quality and boosting your bottom line.

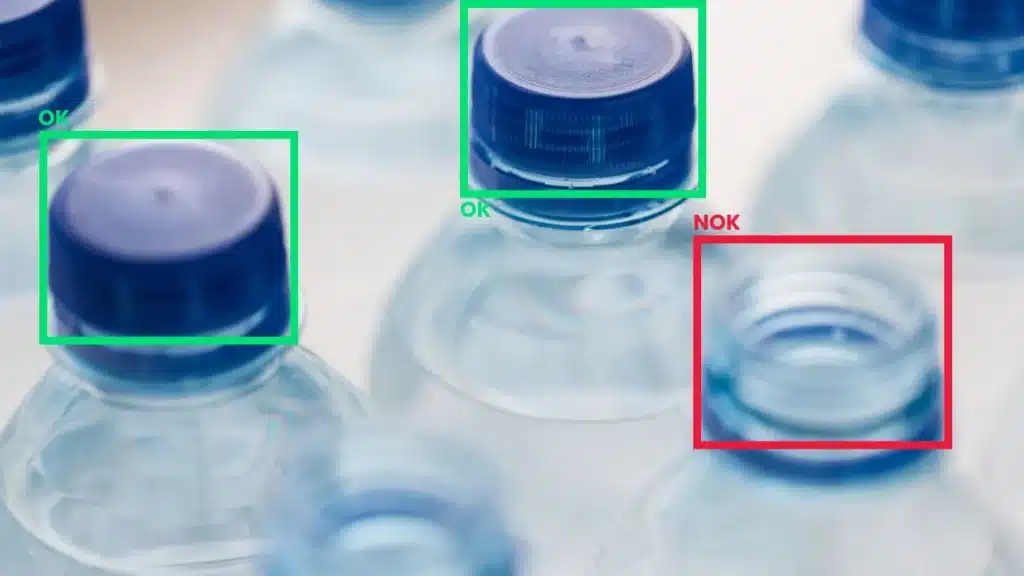

How EasyODM Quality Control Works?

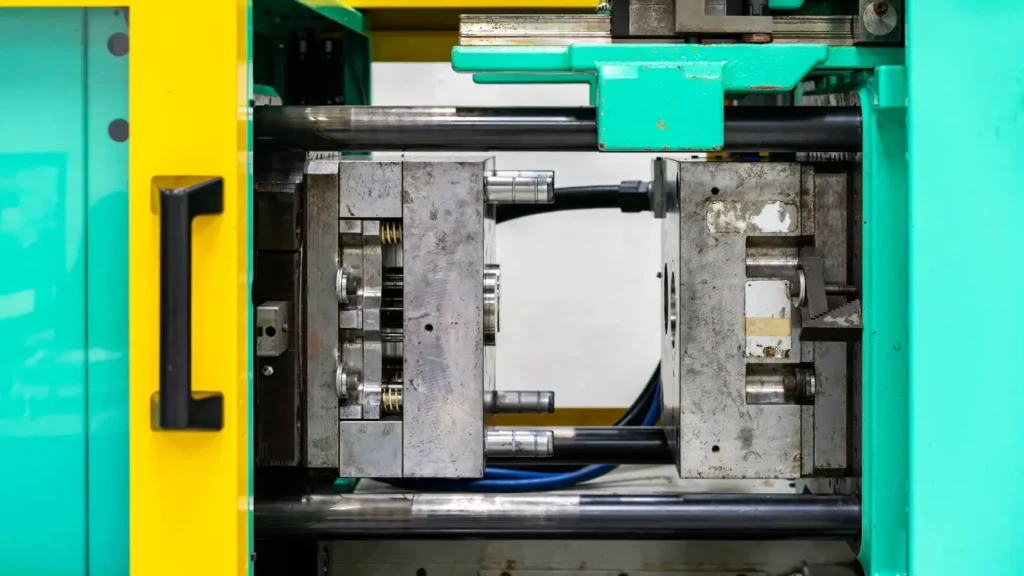

EasyODM integrates seamlessly into your production line, detecting plastic product defects and ensuring smooth 24/7 operation.

Quality Inspection at Every Step of Plastic Manufacturing

AI transforms processes, ensuring precise and efficient production across different types of plastic manufacturing.

What Types of Plastic Products Can AI Inspection Assess?

AI ensures quality control for every aspect of plastic production, from raw materials to the final product.

FAQ – AI In Plastic Industry

Get quick answers to common queries regarding AI quality inspection and its impact on plastic manufacturing processes.