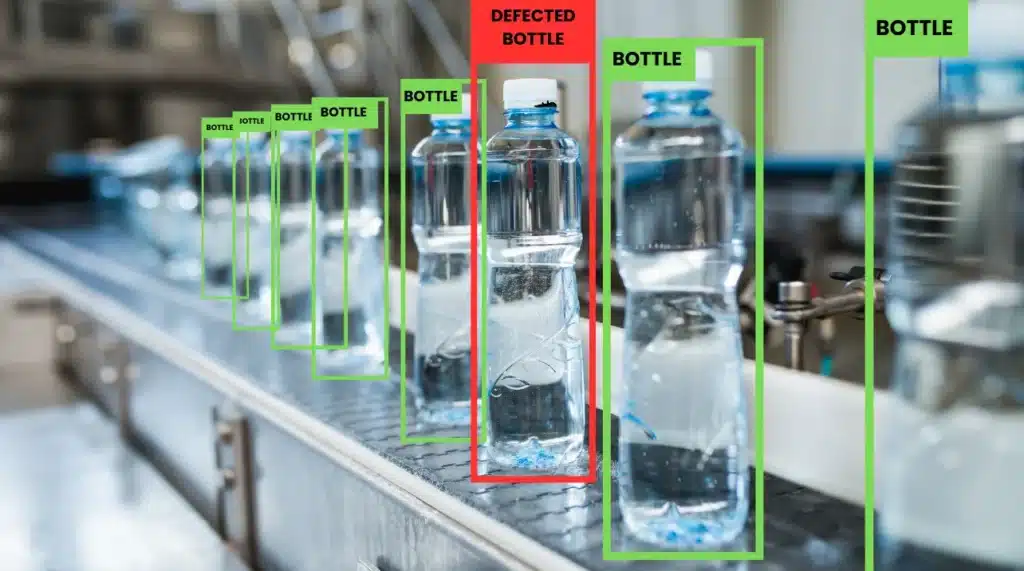

YOLO object detection is a fast object detection algorithm used in computer vision. It’s very useful for detecting defects in factory settings because of its speed and precision. This makes it especially useful for fast-paced environments where efficiency is key.

How YOLO Evolved

There are 10 major versions of YOLO object detection. The system has changed a lot since it was first made. Each new version tried to make YOLO faster and more accurate. These changes improved how YOLO finds objects in images.

Key Features of YOLO Object Detection

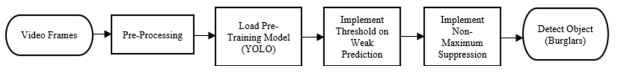

- Real-time processing: YOLO can check video streams quickly, which is great for live monitoring. This capability allows for immediate analysis of video feeds, enabling timely responses to detected objects or defects

- Accuracy: The system balances speed and precision well.

- Adaptability: You can train YOLO to find different objects or defects.

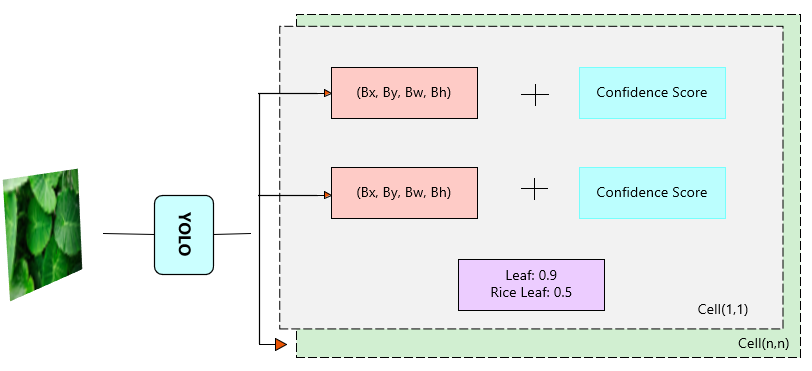

- Multiple object detection: It can spot many objects in one image at once.

- Version options: Different YOLO versions work better for specific tasks or hardware.

YOLO in Industry: Real-World Examples

Manufacturing

YOLO object detection helps with quality control in manufacturing. It can spot defects in products on assembly lines. The system can check multiple items at once, which speeds up inspections. YOLO object detection can also be retrained for new product lines.

Agriculture

In farming, YOLO object detection helps monitor crops and find pests. It can spot signs of disease or pests. This early detection helps farmers act quickly to protect their crops.

YOLO was also used in a recent study to count citrus fruits on trees. The study concluded that the system had achieved a 90.83% accuracy rate.

This improved algorithm has better recognition accuracy and counting precision in complex environments, which leads to better detecting, tracking, and counting of the citrus fruits.

Automotive

The car industry uses YOLO object detection for quality control and driver assistance systems. In factories, it helps find defects in car parts. For driver assistance, YOLO identifies road signs, people, and other vehicles.

Security and Surveillance

YOLO object detection improves security systems by detecting threats in real time. It can spot suspicious objects or behaviors in residential areas with high accuracy. The system can process many camera feeds at once, making large-scale surveillance more efficient. The system helped police respond to problems faster.

EasyODM’s Integration of YOLOv8 for Object Detection

EasyODM has integrated YOLOv8 into its machine vision systems for object detection and defect monitoring. YOLOv8 helps EasyODM detect issues in different manufacturing processes.

The system is capable of finding defects in various industries, from manufacturing to agriculture and more. It’s used to inspect items on production lines, and in laboratories, in real-time. This leads to faster and more efficient quality control and fewer defects.

How to Use YOLO Object Detection for Defect Monitoring

- Get data: Start by gathering a collection of images that show both defect-free and defective items. The more examples you have, the better your model will learn.

- Label data: Mark the areas in each image where the defects appear. This helps the model recognize what a defect looks like and where to find it.

- Choose a model: Pick the version that best matches your needs, considering factors like speed, accuracy, and the hardware you’ll be using.

- Train: Use the labeled data to train your YOLO model, teaching it to recognize defects based on the images you’ve provided.

- Test: After training, run tests to check how well the model detects defects. Make adjustments if necessary to improve accuracy.

- Use it: Deploy the trained model in the environment where it will be used, such as an assembly line or quality control system.

- Keep improving: Continuously monitor its performance and update the model with new data to maintain accuracy and adapt to changes.

Challenges to Think About

- Lighting: Consider using controlled lighting setups or adjusting camera settings to minimize shadows and reflections that could affect detection accuracy

- False alarms: Adjust the YOLO object detection model to reduce false positives while maintaining its ability to detect real defects.

What’s Next for YOLO Object Detection

In the future we might see YOLO get better at spotting small or odd-shaped objects. This could make it more useful in places like electronics manufacturing, where tiny parts matter.

As AI technologies advance, future iterations of YOLO may incorporate more autonomous learning capabilities, potentially enabling the system to identify new defects with less human intervention.

YOLO could also start working with other AI systems. For example, it might team up with robots in factories. YOLO could spot a defect, and the robot could fix it right away. This team-up could make factories much more efficient.

Tips for Using YOLO Object Detection Well

- Have a clear goal: Know what you want to find and why.

- Get good data: Make sure your training data looks like real-world situations.

- Make more data: Change existing images to increase your dataset.

- Adjust settings: Fine-tune the model to work best for your needs.

- Update often: Retrain with new data to keep it accurate.

- Use with other tools: Combine YOLO object detection with other methods for better results.

YOLO’s Limits and Other Options

YOLO is great, but it’s not always the best choice. Here are some limits:

- Small objects: YOLO’s object detection can have trouble with very small things in images. This limitation may lead to missed detections when analyzing images with tiny components, such as those found in electronics.

- Crowded scenes: It might not work as well when there are lots of objects close together.

- Odd shapes: Objects with unusual proportions can be hard for YOLO to spot.

For these cases, you might try other options. Faster R-CNN is better for finding small objects. RetinaNet focuses on improving detection of hard-to-classify objects, including those in crowded scenes. SSD (Single Shot Detector) is another fast option for object detection.

Conclusion

YOLO object detection is a powerful tool for finding objects and defects in many industries. It’s fast, accurate, and can be used in lots of different ways.

Despite its limitations, ongoing advancements ensure that YOLO continues to evolve and improve. As it improves, we’ll likely see it used in even more places to make work faster and more accurate.