When it comes to technology, we often hear buzzwords like ‘artificial intelligence’ and ‘machine learning’. But have you ever heard of machine vision?

This cutting-edge technology is taking the world by storm, and it’s revolutionizing the way we see the world around us. Put simply, machine vision is the ability of machines to ‘see’ and understand the world like humans do.

It uses advanced algorithms and sensors to analyze images and video, and then makes decisions based on that data. Sounds like something out of a sci-fi movie, right? Well, it’s not.

Machine vision is already being used in a variety of industries, from manufacturing to healthcare, and it’s changing the game in ways we never thought possible.

So, let’s take a closer look at what machine vision is, how it works, and why it’s so important.

Key Takeaways

- Machine vision is a technology that enables machines to see and analyze visual data like humans do, using advanced algorithms and sensors.

- It has numerous applications across industries such as manufacturing, healthcare, and transportation, and can significantly increase productivity, reduce costs, and improve efficiency and accuracy.

- Machine vision systems consist of three main components: camera, processor, and software, and use digital images to detect even the smallest defects or deviations from the standard.

- Effective communication and connectivity are essential for machine vision to function optimally, and high-speed communications and connectivity are crucial for processing and analyzing vast amounts of data in real-time.

What is machine vision and how does it work?

So, let’s talk about machine vision – an exciting technology that’s revolutionized the way we see and perceive the world around us.

Machine vision can be defined as a branch of artificial intelligence that enables machines to see and interpret images and video data. This technology works by using advanced algorithms and computer vision techniques to analyze visual information and make decisions based on that data.

Machine vision has numerous applications across industries, such as manufacturing, healthcare, and transportation. There are different types of machine vision processes, including image processing, pattern recognition, and object tracking.

The key components of a machine vision system include cameras, lighting, image sensors, and processing units.

Definition of machine vision

You might be wondering, what exactly is machine vision? Well, it refers to the ability of machines to interpret and understand visual data from the world around them, just like humans do.

This technology is also known as computer vision or industrial machine vision and it involves the use of cameras, sensors, and algorithms to enable machines to detect, recognize, and analyze objects and their surroundings.

With the help of vision technology, machines can perform a wide range of tasks, such as quality control in manufacturing, object detection in autonomous vehicles, and facial recognition in security systems.

Here are three key benefits of using a machine vision system:

- Increased accuracy: Machine vision systems are highly accurate and can detect flaws or defects that may be missed by human inspectors.

- Improved efficiency: By automating inspection and analysis tasks, machine vision systems can significantly increase productivity and reduce costs.

- Enhanced safety: Machine vision systems can be used to monitor and detect potential safety hazards in industrial settings, helping to prevent accidents and injuries.

Overall, machine vision technology has the potential to revolutionize many industries and improve the way we live and work.

Working of machine vision technology

Picture this: cameras, sensors, and algorithms come together to create a high-tech system that can interpret and analyze visual data, making it possible for machines to perceive the world around them. This is the essence of machine vision technology. The hardware and software of a machine vision system work together to capture and process images, allowing for vision processing and analysis.

At the heart of machine vision technology is the imaging system, which captures visual data and feeds it into the system for analysis. The imaging system can be made up of various hardware components, including cameras, lenses, lighting, and sensors. These components work together to capture high-quality images that can be processed and analyzed by the software. The software component of the system is responsible for processing and analyzing the visual data, using sophisticated algorithms to interpret the images and extract meaningful information. Together, the hardware and software components of a machine vision system create a powerful tool for visual analysis and interpretation.

To further illustrate the capabilities of machine vision technology, consider the following table:

| Response | Example |

|---|---|

| Amazement | can detect and identify objects in real-time, even in complex and dynamic environments. |

| Efficiency | can automate tasks that would otherwise be time-consuming or impossible for humans to perform. |

| Accuracy | can achieve high levels of accuracy and precision in their analysis and interpretation of visual data. |

| Safety | can be used to monitor and ensure the safety of workers in hazardous environments. |

| Innovation | technology is driving innovation across a wide range of industries, from manufacturing to healthcare to transportation. |

This table highlights some of the emotional responses that can be evoked when considering the capabilities of machine vision technology. From amazement at its real-time object detection to the safety benefits it can provide, machine vision technology is a powerful tool for improving efficiency, accuracy, and innovation in a variety of industries.

Applications of machine vision system

Let’s explore some of the ways this cutting-edge technology is being used in a variety of industries. Machine vision systems are becoming increasingly popular in the modern world due to their ability to automate tasks and improve efficiency.

One common application of machine vision is in the manufacturing industry, where the technology is used to inspect products for defects, measure parts, and guide robots during assembly.

Additionally, industrial machine vision is being used in fields like agriculture and forestry to optimize crop yields and monitor plant health.

As technology continues to advance, it’s likely that we’ll see even more innovative vision applications in the near future.

Types of machine vision processes

If you’re wondering how computers are able to analyze images, it’s through complex algorithms that break down the visual data into various types of information. This process is known as machine vision, which involves the use of cameras and software to capture and analyze images.

There are different types of machine vision processes depending on the application, but they all involve the same basic concept of using cameras to capture visual data.

One common type is vision inspection, which is used to detect defects or abnormalities in products during the manufacturing process. This involves using a machine vision camera to capture an image of the product, which is then analyzed by software for any irregularities.

Another type is object recognition, which is used to identify and classify objects in an image. This is commonly used in fields such as robotics and self-driving cars, where machines need to be able to identify and navigate around objects in their environment.

Components of machine vision system

Now that we’ve learned about the different types, let’s dive deeper into the components.

At its core, a machine vision system has three main components: the camera, the processor, and the software. The camera is the hardware component that captures the images or video for analysis.

The processor is responsible for analyzing the images and making decisions based on the data it receives. Finally, the software is the brain of the system that controls the image analysis and decision-making process.

Within each of these components, there are sub-components that work together to create a cohesive system. Let’s explore each of these components further in the nested bullet point list below.

- Camera:

- Processor:

- Central Processing Unit (CPU)

- Graphics Processing Unit (GPU)

- Random Access Memory (RAM)

- Software:

- Image processing algorithms

- Decision-making algorithms

- Graphical User Interface (GUI)

Understanding the components of a machine vision system is crucial for anyone working in this field. As a team, we need to have a solid understanding of how each of these components works together to achieve the desired outcome.

By mastering the hardware and software components, we can create systems that are efficient, effective, and reliable.

What are the benefits of using machine vision technology?

With enhanced inspection accuracy and precision, manufacturers can ensure their products meet quality standards with ease. Additionally, increased production efficiency and throughput rates can save time and money, while reducing errors and defects.

Overall, machine vision can lead to cost savings in labor and materials, as well as improved product quality and consistency.

Enhanced inspection accuracy and precision

You can improve your inspection accuracy and precision with machine vision technology. You can ensure that every part or product that goes through the quality control process is checked thoroughly and accurately. This technology uses digital images to detect even the smallest defects or deviations from the standard, making it an efficient and reliable way to maintain high levels of quality control.

To give you a better idea, here is a table that outlines the steps involved in a typical inspection process:

| Step | Description | Example |

|---|---|---|

| 1 | Image Acquisition | A camera captures an image of the product |

| 2 | Image Processing | The image is analyzed to detect defects or deviations |

| 3 | Decision Making | The system decides whether the product passes or fails |

| 4 | Action | The product is sorted or rejected based on the decision |

| 5 | Feedback | Data is collected to improve the inspection process |

Using this process, machine vision technology can quickly and accurately inspect products, reducing the risk of errors and improving overall quality control. By incorporating this technology into your inspection process, you can ensure that every product that leaves your facility meets the highest standards of quality.

Increased production efficiency and throughput rates

By implementing machine vision technology, you’ll see a significant boost in your production efficiency and throughput rates. This will allow you to produce more products in a shorter amount of time.

Machine vision allows for faster and more accurate inspection of products on the production line. With the use of smart cameras, it can quickly identify defects or inconsistencies in products, ensuring that only high-quality items are passed through the line.

In addition, it can help optimize production processes by identifying areas where improvements can be made. For example, it can identify bottlenecks or inefficiencies in the production line, allowing for adjustments to be made to increase throughput rates. This not only leads to increased productivity, but also a reduction in production costs.

Cost savings in labor and materials

By implementing machine vision technology in industrial applications, businesses can save money on both labor and materials.

Firstly, using automated machines with machine vision capabilities can significantly reduce labor costs. These machines are able to perform tasks that would normally require human intervention, such as quality control inspections, sorting, and packaging. This means that businesses can save on labor costs by reducing the number of workers needed to perform these tasks. Additionally, machine vision can reduce the likelihood of errors or defects in products, further decreasing the need for manual labor to correct these issues.

By automating these tasks, businesses can reallocate their resources to other areas of the production process, improving overall efficiency and productivity.

Secondly, it can also save businesses money on materials. With the ability to detect defects and inconsistencies in products, machine vision can help reduce waste by catching errors early on in the production process. This can save businesses money by reducing the need for additional materials to fix or replace defective products. Additionally, machine vision can help optimize the use of materials by ensuring that they are being used efficiently and effectively.

By reducing waste and improving material usage, businesses can save money and improve their ROI.

Improved product quality and consistency

Imagine receiving a product that looks and performs exactly the same every time, giving you the confidence that you can rely on its quality and consistency. This is possible with the help of machine vision and vision inspection systems.

By utilizing advanced cameras and software, machine vision can detect even the slightest defects or variations in a product, ensuring that each one meets the same high standard. Not only does machine vision improve product quality, but it also ensures consistency in production.

By detecting any inconsistencies, the system can alert workers to make adjustments before further production occurs. This not only saves time and money, but it also ensures that every product that leaves the factory is of the same high quality.

With machine vision, manufacturers can rest assured that their products will meet the same standards every time, resulting in increased customer satisfaction and loyalty.

Reduced errors and defects

Reducing errors and defects in production can increase profits for businesses. For example, a study found that companies that decrease defects by just 1% can see a 10% increase in profits. This is where machine vision comes in, as it has the ability to significantly reduce errors and defects in production.

By utilizing inspection systems that use machine vision technology, businesses can detect and correct errors at a much faster rate than traditional methods. Machine vision can help reduce errors and defects in production in many ways. Here are a few examples of how it can be used:

- Identifying defects in products before they leave the manufacturing line

- Ensuring that products meet specific quality standards and specifications

- Identifying areas in the manufacturing process that need improvement

- Detecting errors that might be missed by human inspectors

Overall, the use of machine vision technology in inspection systems can help businesses improve their bottom line by reducing errors and defects in production.

What industries use machine vision systems?

There are several, including industrial and manufacturing, pharmaceutical and medical, automotive, aerospace, and food and beverage.

These industries benefit greatly from the increased efficiency and accuracy that machine vision technology provides.

Industrial and manufacturing

In the industrial and manufacturing sectors, machine vision technology is becoming increasingly vital for improving efficiency and ensuring consistent product quality. With the advancements in smart camera technology, machine vision systems can now perform complex tasks, such as identifying defects in products, tracking inventory, and monitoring production lines.

Here are three ways that machine vision is transforming the industrial and manufacturing sectors:

- Quality Control: inspect products for defects, ensuring that only high-quality products reach the market. This helps reduce waste and improves customer satisfaction.

- Automation: automate several tasks in the manufacturing process, such as monitoring and controlling production lines, reducing the need for human intervention. This leads to increased efficiency and productivity.

- Safety: detect potential safety hazards in the workplace, such as equipment malfunctions, and alert workers before an accident occurs. This helps create a safer work environment for employees.

Overall, this technology is revolutionizing the industrial and manufacturing sectors. It is helping companies reduce costs, increase efficiency, and improve product quality.

Pharmaceutical and medical

The healthcare industry is experiencing a technological revolution with the integration of advanced automation systems. Machine vision has become an essential tool in the medical and pharmaceutical sectors.

In the pharmaceutical industry, it is used to inspect the quality and integrity of capsules, tablets, and vials. It can detect defects such as cracks, chips, and even particles that are invisible to the naked eye. This ensures that only safe and effective medicines are distributed to the public.

In the medical field, machine vision is used in diagnostic imaging equipment, such as X-rays and MRIs. It helps doctors identify and diagnose various health conditions accurately. With the help of machine vision, healthcare professionals can provide better and more efficient care to patients.

Automotive

Get ready to experience the future of driving as advanced automation systems revolutionize the automotive industry.

Automotive companies are increasingly incorporating cameras and other sensors into their vehicles to improve safety, efficiency, and overall performance.

One of the main applications of machine vision in the automotive industry is inspection. Cameras can be used to inspect various parts of a vehicle, such as the engine, chassis, and body, to ensure that they meet quality standards.

Machine vision can also be used for defect detection, identifying any flaws or imperfections in the manufacturing process. By using machine vision for inspection, automotive companies can reduce the likelihood of recalls and improve overall customer satisfaction.

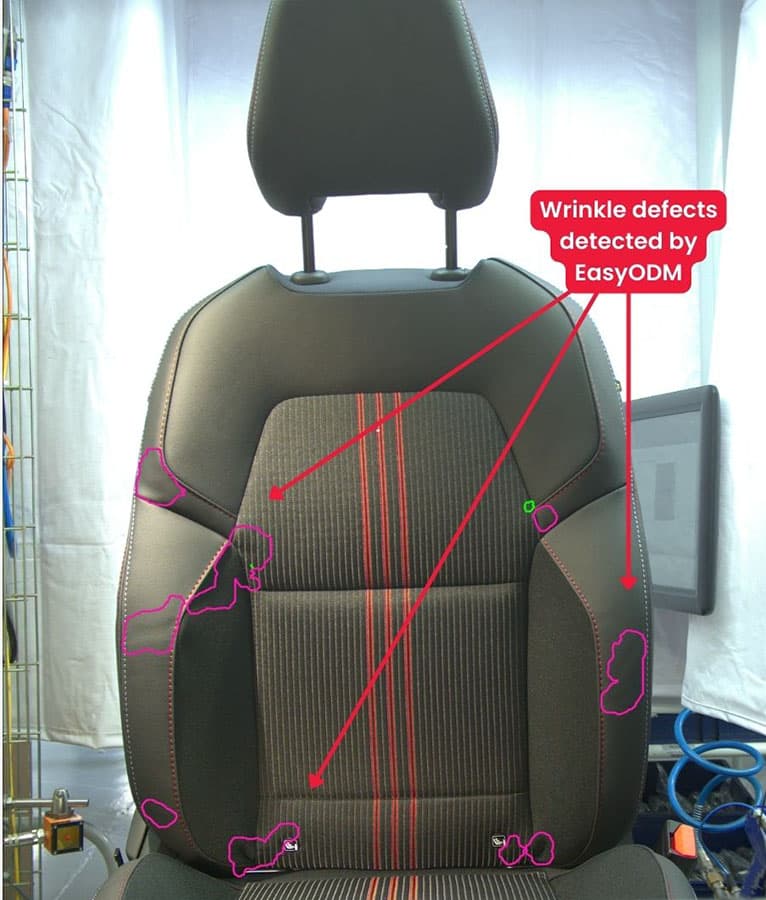

In addition to its applications in the automotive industry, machine vision technology has proven valuable in detecting quality issues in textiles. EasyODM software, for instance, has emerged as a reliable solution for identifying textile quality issues with ease.

A recent case study focusing on automotive seats showcases the effectiveness of EasyODM software, achieving an impressive 99% accuracy in detecting wrinkles as a critical defect.

This success highlights the potential of machine vision technology to enhance quality control processes in various industries, including textiles and automotive manufacturing.

By leveraging AI-powered inspection systems like EasyODM, automotive companies can ensure both the integrity of their vehicles and the quality of the materials used in their production.

Aerospace

Buckle up and prepare for takeoff as the aerospace industry reaches for the stars, soaring to new heights with cutting-edge technology that unlocks the secrets of the universe.

As we look to the future, machine vision is set to become a vital component of aerospace technology. Computer vision systems and machine vision inspection will play a significant role in ensuring the safety and reliability of aircraft and spacecraft.

Here are four ways that machine vision is already being utilized in the aerospace industry:

- Quality Control: detect defects and imperfections in aerospace components that may not be visible to the human eye, ensuring that only the highest quality parts make it into the final product.

- Maintenance and Repair: identify wear and tear on aircraft and spacecraft, allowing for timely maintenance and repair to keep these vehicles in optimal flying condition.

- Navigation and Guidance: navigate through challenging environments, such as extreme weather conditions or unfamiliar terrain.

- Space Exploration: capture images of distant planets and galaxies, and helping scientists to better understand the universe beyond our own planet.

Food and beverage

Indulge in the delectable flavors of the food and beverage industry, tantalizing your taste buds and satisfying your cravings with every bite and sip. But have you ever wondered how manufacturers ensure that the food and beverages we consume meet the highest quality standards?

In the food and beverage industry, machine vision inspection systems are used to detect defects, contamination, and other quality issues that might compromise the safety and integrity of the products. This ensures that only the best products make it to the market and eventually to our plates and glasses.

Key components

These components include the machine vision camera, lighting and illumination, optics and lenses, processing hardware and software, and communications and connectivity.

As we discuss each component, we’ll explore how they work together to create a comprehensive vision system that can detect, analyze, and interpret images with speed and accuracy.

Machine vision camera

As the adage goes, “a picture is worth a thousand words”, and with a machine vision camera, you can capture images that will help you make critical decisions in your manufacturing process.

This camera is designed to work with a wide range of light sources, including LED, fluorescent, and natural light. This makes it easier to capture images in any lighting condition, ensuring that you get the best possible image quality.

The machine vision camera is also equipped with an optical system that is designed to produce high-resolution images. This optical system includes a lens and a sensor that work together to capture images with incredible detail and accuracy.

This kind of camera is equipped with a range of features that make it easy to use, including autofocus, autoexposure, and image stabilization.

Lighting and illumination

You can greatly enhance the quality of your captured images by paying attention to lighting and ensuring proper illumination. Lighting is an essential component of any machine vision system. A well-designed lighting system can help improve accuracy and consistency in image capture.

Additionally, proper lighting can help highlight important features of the object being inspected, making it easier for the machine vision system to analyze the image. An integrated system that uses proper lighting and illumination can help to optimize image quality and reduce errors.

It’s important to consider factors such as the type of lighting source, angle and intensity of lighting, and color temperature when designing a lighting system. By ensuring that lighting is optimized, you can help to ensure that your machine vision system provides accurate and reliable results.

Optics and lenses

Using the right lenses is like wearing the perfect glasses that allow you to see the world with clarity and precision, enhancing the details and improving the accuracy of the images captured.

In machine vision, optics and lenses play a crucial role in capturing high-quality images, which are then processed by the system to extract relevant information.

The lens focuses light onto the sensor, and the sensor converts this light into an electrical signal that’s processed by the system. The quality of the lens determines how much light is transmitted, how sharp the image is, and how much distortion is present.

Optics and lenses come in different shapes and sizes, each designed to perform specific tasks. For instance, telecentric lenses are used to capture images of objects that are the same size, while fisheye lenses are used to capture a wide field of view.

The choice of lens depends on the application and the desired outcome. The lens is just one part of the machine vision system; the processing system also plays a critical role in analyzing the images captured by the lens.

Therefore, it’s essential to use high-quality lenses that can capture images with precision and accuracy, which can then be processed effectively by the system.

Processing hardware and software

The efficiency of the image processing system heavily relies on the quality and compatibility of its hardware and software components. Machine vision systems typically consist of a camera, a processing unit, and software that implements computer vision algorithms to extract information from the images. The processing hardware can range from a simple microcontroller to a high-end computer with multiple processing units.

On the other hand, the software component is responsible for interpreting the raw data captured by the camera and extracting relevant information. There are various software libraries and frameworks available that can be used to develop machine vision applications. Some of the popular ones include OpenCV, Matrox Imaging Library, and Halcon. These software components provide a wide range of functionalities such as image filtering, feature extraction, object recognition, and tracking. By using such software tools, developers can create machine vision applications that are efficient, reliable, and scalable.

| Processing Hardware | Software |

|---|---|

| Microcontroller | OpenCV |

| DSP | Halcon |

| FPGA | Matrox Imaging Library |

| GPU | VisionWorks |

| CPU | TensorFlow |

The processing hardware and software components are essential to the success of any machine vision application. The hardware must be capable of capturing high-quality images, and the software must be able to process the data efficiently and accurately using computer vision algorithms. By leveraging the right combination of hardware and software, developers can create machine vision applications that can automate various tasks, improve efficiency, and reduce errors.

Frequently Asked Questions

What is the difference between machine vision and computer vision?

Machine vision and computer vision are often used interchangeably, but there’s actually a subtle difference between the two.

Machine vision refers to the use of cameras and image processing software to automate tasks that would typically require human intervention. It’s a subfield of computer vision, which encompasses a broader range of capabilities, including image recognition, scene reconstruction, and object tracking.

While machine vision is primarily concerned with automating specific tasks, such as inspecting parts on an assembly line or sorting products by color, computer vision is focused on creating systems that can perceive and understand the world in a similar way to humans. This involves developing algorithms and software that can analyze images and video streams, recognize patterns and objects, and make decisions based on that information.

What is industrial machine vision?

Industrial machine vision encompasses all machine vision applications used in the manufacturing, inspection, and quality control of industrial products. It plays a vital role in ensuring product quality and consistency.

What is a machine vision lens?

A specialized lens designed to work with machine vision cameras to provide the necessary field of vision and focus for image capture and analysis.

What is machine vision?

It is an imaging technology that uses computer software and hardware to analyze and interpret images and provide information to controllers for inspection, positioning, orientation and sorting tasks in automation and artificial intelligence applications.

Conclusion

So there you have it, folks! Machine vision is an exciting and rapidly advancing technology that is transforming countless industries.

From manufacturing and healthcare to agriculture and transportation, machine vision systems are helping businesses optimize their processes, improve quality control, and increase efficiency.

As I wrap up this article, I can’t help but imagine a world where machines can see and interpret the world around them in the same way that we humans do. It’s a thrilling prospect, and one that inspires me to keep learning more about this incredible field.

Who knows what amazing breakthroughs and applications we’ll see in the years to come? One thing is for sure: the future of machine vision is looking very bright indeed.

Unlock Your Business Potential With AI!

Book a consultation with our expert and discover tailored solutions to boost your business success. Don’t miss out on this opportunity to gain personalized insights and strategies.

Gediminas Mickus

Business Development Manager

Limited seats available - Act now!