This case study focuses on a collaborative project aimed at enhancing quality control practices for solid wood lamellas and parquet in the hardwood flooring industry.

The study explores the challenges faced by a leading hardwood flooring manufacturer, the implementation of automated visual inspection software leveraging machine vision and AI, and the anticipated benefits of this project.

Client Overview

The client is the second-largest hardwood flooring company in Europe and the leader in the premium segment. The company known for their commitment to delivering exceptional craftsmanship and high-quality products.

As a prominent player in the wood industry, they continually strive to improve their processes and maintain their reputation for excellence in wood quality control.

Challenges

The client encountered significant challenges in efficiently inspecting solid wood lamellas and parquet for quality parameters.

Manual inspection processes proved time-consuming, labor-intensive, and prone to human error.

This posed difficulties in meeting production demands while ensuring consistent quality control for wood products.

Solution

To address the client’s challenges, EasyODM machine vision software was identified as the ideal solution.

With advanced AI algorithms, computer vision capabilities, and a user-friendly interface, EasyODM offered the potential to transform the client’s quality control processes.

Implementation

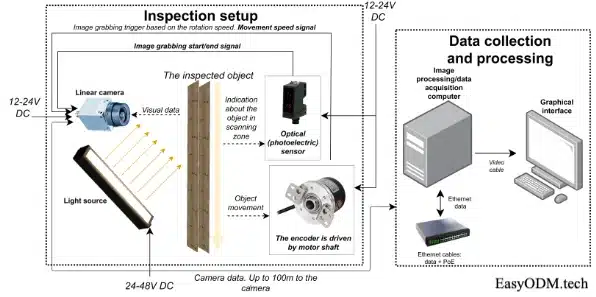

The implementation of the automated visual inspection software involved integrating it seamlessly into the client’s existing production setup.

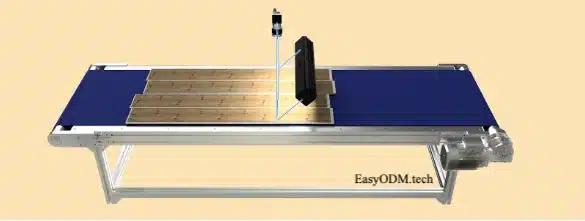

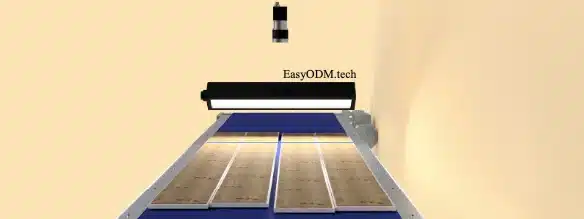

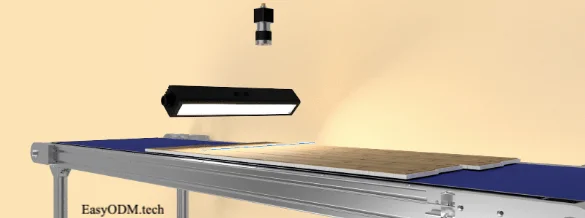

Video feeds from on-site cameras were captured, while advanced machine learning algorithms and computer vision technology analyzed the data for defects and quality parameters specific to wood products.

Basic concept of hardwood lamella photo collection with local illumination and linear camera

Customization

The software was tailored to address the specific quality parameters associated with solid wood lamellas and parquet in the wood industry.

The machine learning algorithms were fine-tuned to detect surface imperfections, color variations, knots, cracks, and other defects commonly found in hardwood flooring, ensuring rigorous wood quality control.

Anticipated Benefits

- Enhanced Efficiency: The adoption of automated visual inspection is expected to significantly reduce manual inspection time and effort, improving overall efficiency in quality control for wood products.

- Improved Product Quality: By leveraging advanced machine learning algorithms and computer vision technology, the software is anticipated to enhance defect detection capabilities, ensuring a higher standard of product quality and minimizing the risk of subpar wood products reaching the market.

- Cost Savings: The automation of the inspection process is expected to reduce labor costs associated with manual inspection and minimize the potential for human errors, resulting in cost savings (ROI calculator) over time in wood quality control.

- Consistent Quality: The automated visual inspection system with machine vision is anticipated to provide consistent and objective assessments, helping the client maintain their reputation for delivering high-quality hardwood flooring and other wood products.

- Data-Driven Insights: The collection and analysis of data during the inspection process using AI will offer valuable insights for continuous process improvement and informed decision-making in wood quality control, enabling the client to further optimize their practices in the wood industry.

Frequently Asked Questions

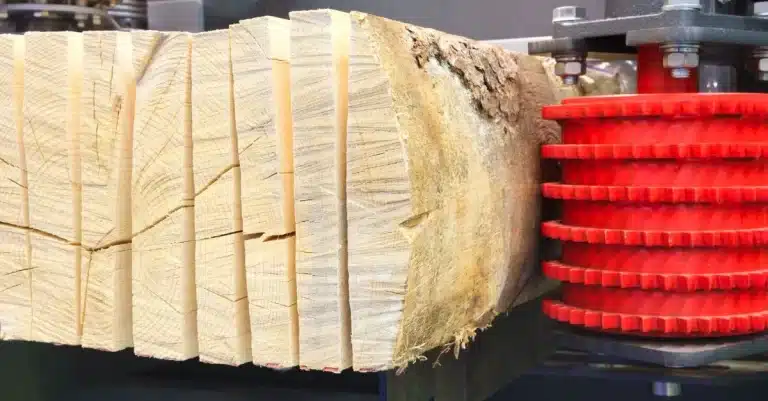

Lamella flooring refers to a type of engineered wood flooring where the top layer is made up of thin strips or lamellas of solid wood. These lamellas are carefully selected and assembled to create a visually appealing and durable flooring option.

Lamella flooring is manufactured by carefully cutting and arranging thin strips of solid wood to create the top layer. The lamellas are typically bonded together using adhesive and placed on top of a core layer, which provides stability and strength to the flooring.

Yes, EasyODM software is designed to detect even subtle quality issues that may be challenging to identify manually. Its advanced algorithms and machine vision capabilities enable it to analyze the lamella flooring with precision, ensuring thorough quality inspection.

Yes, AI-powered software is highly adaptable and can be customized to meet evolving quality standards and requirements in the lamella flooring industry. It can be trained to recognize specific defects and adapt to changes in quality criteria as needed.

Conclusion

Through the implementation of automated visual inspection software leveraging machine vision and AI, the client aims to enhance their quality control practices, improve efficiency, and elevate product quality in hardwood flooring and other wood products.

This case study highlights their journey, the challenges they faced in wood quality control, and the anticipated benefits they expect to achieve through this ongoing project.

By leveraging cutting-edge technology such as machine vision and AI in wood quality control, the client strives to stay at the forefront of the wood industry, ensuring customer satisfaction and maintaining their position as a leader in delivering high-quality wood products.

Not Sure If AI Can Help Your Business? Let’s Talk!

Book a consultation with our expert to explore how AI solutions could fit your unique business needs. Whether you’re curious or uncertain, we’re here to discuss and guide you.

Gediminas Mickus

Business Development Manager