EasyODM, a leading provider of automated visual inspection software utilizing AI and computer vision, has partnered with a prominent textile manufacturer to revolutionize fabric quality control.

The implementation of EasyODM’s solution has transformed the inspection process, optimizing efficiency, minimizing defects, and reducing production costs.

Client Overview

The client for this case study is the largest sportswear manufacturer in the Baltic States. With a rich history, the company is a prominent player in the sportswear industry.

Their commitment to quality and innovation makes them an ideal partner for implementing cutting-edge solutions like EasyODM’s computer vision-based fabric quality inspection system.

The Problem

The textile industry relies heavily on manual visual inspection, which is time-consuming, subject to human error, and costly. EasyODM recognized the need for an automated solution that could provide flawless and efficient fabric quality inspection.

Solution Overview

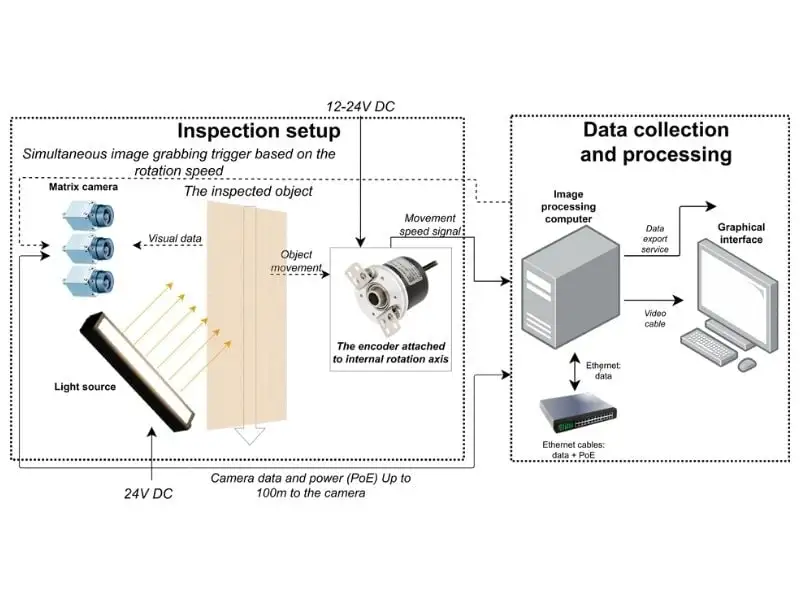

EasyODM proposed an innovative concept that integrates computer vision technology into the existing fabric inspection stations. This solution automates the visual inspection process, ensuring higher accuracy and speed in defect detection.

Key Features of the Solution:

- Integration of even and consistent LED lighting for optimal illumination.

- Multiple cameras for comprehensive fabric observation.

- Advanced algorithms for defect detection and analysis.

- Real-time monitoring and statistical data collection.

- User-friendly application interface for system control and data visualization.

- Compatibility with existing fabric inspection setups.

Implementation Details

EasyODM’s solution involves the integration of three matrix cameras with global shutter capabilities, equipped with protective enclosures and lenses to safeguard against dust and debris.

The fabric is illuminated by a specialized LED system, providing consistent and even lighting. The system also includes an encoder to measure fabric movement and ensure synchronized data analysis.

Benefits and Results

- Optimized Accuracy: EasyODM’s system is projected to achieve an impressive 99% accuracy rate in defect recognition, ensuring meticulous quality control.

- Enhanced Efficiency: The software is anticipated to significantly outpace human inspection, resulting in a substantial boost in production speed.

- Cost Savings: By minimizing defects and reducing manual labor, clients can expect significant annual cost savings.

- Real-Time Insights: The system will provide immediate access to statistical defect data and their precise locations on fabric, facilitating timely corrective actions.

Future Potential

Beyond textiles, EasyODM’s solution can be tailored for industries like glass, pharmaceuticals, and wood manufacturing. The software’s flexibility and adaptability make it a versatile tool for quality control across various sectors.

Conclusion

EasyODM’s partnership with the textile manufacturer demonstrates how computer vision and AI can elevate quality inspection to new heights.

With its remarkable accuracy, efficiency, and adaptability, EasyODM’s solution is transforming the way industries approach quality control, ensuring flawless production, cost savings, and enhanced brand reputation.

Unlock Your Business Potential With AI!

Book a consultation with our expert and discover tailored solutions to boost your business success. Don’t miss out on this opportunity to gain personalized insights and strategies.

Gediminas Mickus

Business Development Manager

Limited seats available - Act now!