The automotive industry is in a state of continuous evolution, and at its heart lies the transformative power of artificial intelligence (AI) technology.

This digital revolution has touched every facet of the industry, and one area that stands to gain immensely is the realm of car seat manufacturing.

Imagine a manufacturing process where AI-driven quality inspections not only streamline production but also ensure that the end products meet the highest standards of quality and safety.

This is no longer a distant vision; it’s a reality that leading car seat manufacturers are actively embracing (read the case study).

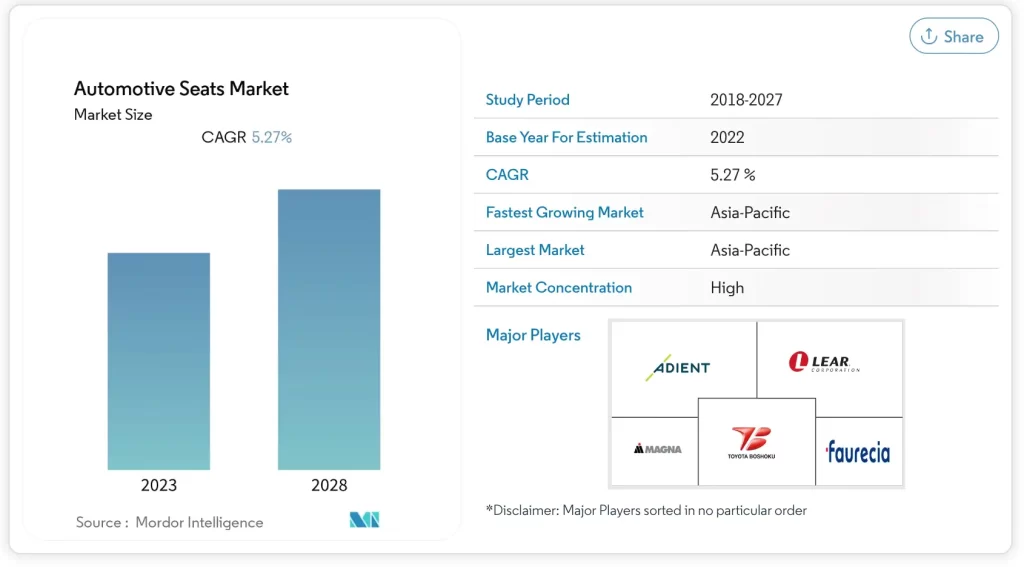

In the ever-changing landscape of the automotive seat market, data speaks volumes. Valued at an impressive USD 80.25 billion, this market segment is projected to soar to USD 109.2 billion, with a remarkable compound annual growth rate (CAGR) of 5.27% over the next five years (according study).

This growth underscores the industry’s responsiveness to innovation and the willingness of manufacturers to invest in cutting-edge technologies.

In this article, we embark on a journey into the world of car seat manufacturing, where AI takes center stage in the pursuit of quality perfection.

We will unravel the multitude of benefits that AI-driven quality assessment brings to this vital industry.

Additionally, we’ll shine a spotlight on key players within this sector who are poised to reap substantial rewards by harnessing the potential of AI.

So, fasten your seat belts as we navigate the exciting future of car seat manufacturing, where AI not only propels efficiency but also propels our industry to unprecedented heights.

Key Takeaways

- AI-powered quality inspection can help top car seat manufacturers identify and resolve wrinkles in car seat materials during production, improving overall efficiency and profitability.

- Traditional manual inspection methods are slow, laborious, and prone to mistakes, leading to more defects in car seat materials.

- Embracing AI quality inspection can enhance the quality control process and ensure that car seat materials meet the desired standards.

- The use of AI technology in quality inspection aligns with the trend of technological advancements in the automotive industry and can contribute to the success of top car seat manufacturers.

The Need for Enhanced Quality Control in Car Seat Manufacturing

The automotive industry is in need of enhanced quality control in car seat manufacturing to ensure customer safety and satisfaction.

With the increasing demand for car seats and the complexity of their design, it is crucial to detect and address any defects in the manufacturing process.

Quality inspection plays a vital role in identifying and rectifying issues such as wrinkles in car seat materials. Traditional manual inspection methods are often slow, laborious, and prone to mistakes, hindering overall efficiency and profitability.

However, advanced AI-powered quality inspection software, like EasyODM, offers a solution. With cutting-edge deep learning algorithms, EasyODM achieves exceptional precision and speed in defect detection, surpassing the capabilities of human inspection.

Benefits of Implementing AI in Quality Assessment for Car Seats

Implementing AI in quality assessment for car seats brings numerous benefits, such as improved efficiency, cost savings, and enhanced accuracy in identifying defects.

By leveraging advanced deep learning algorithms, AI-powered quality inspection software like EasyODM revolutionizes the production cycle and accelerates operational efficiency.

It dramatically reduces inspection time from 1 minute per part (manual process) to just 2.2 seconds per part, resulting in increased productivity and reduced time wastage. Read the full case study here.

Additionally, significant cost savings are achieved through the automation of the quality inspection process, with a return on investment achieved in less than two years.

The AI-based system achieves an exceptional accuracy rate of 99% in wrinkle detection, surpassing the capabilities of human inspection.

EasyODM seamlessly integrates with existing production lines, allowing employees to shift their focus from repetitive inspection tasks to supervising the platform, creating a more efficient and engaging work environment.

| Benefits | Description |

|---|---|

| Improved Efficiency | AI-powered quality inspection software reduces inspection time, increasing productivity. |

| Cost Savings | Automation of the quality inspection process leads to significant cost savings. |

| Enhanced Accuracy | Advanced deep learning algorithms achieve a 99% accuracy rate in defect detection. |

Car seat manufacturers can greatly benefit from implementing AI quality inspection systems, as they can streamline their production processes, reduce costs, and ensure the highest levels of quality control.

By leveraging AI technology, these manufacturers can significantly improve their efficiency in identifying defects, resulting in increased productivity and reduced time wastage.

Furthermore, AI-powered quality inspection systems offer exceptional accuracy, surpassing the capabilities of manual inspection.

This not only helps in maintaining high-quality standards but also reduces the risk of product recalls, enhancing customer satisfaction and brand reputation.

By embracing AI quality inspection, car seat manufacturers can stay ahead of the competition and meet the growing demands of the automotive industry.

Leading Car Seat Manufacturers

When discussing the leading car seat manufacturers that could benefit from implementing AI in quality assessment, it is important to consider companies such as Adient, Lear Corp, Toyota Boshoku, Aisin, and TS Tech Co.

These companies play a significant role in the global automotive seat market and have a strong presence in supplying major OEMs worldwide.

By embracing AI-powered quality inspection, these manufacturers can enhance their overall product quality, increase production efficiency, and reduce the risk of product recalls.

This, in turn, will improve customer satisfaction and maintain their reputation in the industry.

Adient

Adient, founded in 2016 and headquartered in Ireland, is a global leader in manufacturing automotive seats.

With over 250 plants worldwide, it has established itself as an expert in versatile and dependable seating solutions.

Adient’s focus on consumer-friendly innovation and technology has propelled it to be recognized as one of the largest automotive seat manufacturers.

Their research and design efforts are geared towards creating seats that enhance comfort, safety, and overall driving experience through AI-driven advancements.

Lear Corp

Lear Corporation, established in 1917 and based in Michigan, USA, is a Fortune 500 company specializing in car seats and automotive electrical systems.

As a pioneer in the industry, Lear has consistently pushed the boundaries of technology to deliver intelligent in-vehicle experiences for customers.

Leveraging AI, Lear’s manufacturing processes could be optimized for quality, efficiency, and customization even more.

Through its innovative approaches, the company continues to motivate consumers to modify vehicle seating to align with evolving preferences and driving needs.

Toyota Boshoku

Toyota Boshoku, a subsidiary of Toyota Corporation, was founded in 1918 in Japan. As a premium automotive component manufacturer, the company creates seamless driving experiences through its high-quality automobile components.

Toyota Boshoku’s incorporation of AI technologies in seat design and manufacturing has allowed it to tailor seats to individual preferences and vehicle models.

This commitment to customization, coupled with its deep-rooted connection to the Toyota group, positions Toyota Boshoku as a leading force in luxury seat covers and overall driving comfort.

Aisin

Aisin, established in 1949 in Japan and part of the Toyota group, is a Japanese corporation focused on automotive components and systems.

With its goal of being a global leader in vehicle dynamics, Aisin’s manufacturing contributes to its reputation as a world-class automotive seat manufacturer.

By integrating cutting-edge technology and manufacturing excellence, the company is at the forefront of developing seats that enhance safety and comfort.

Aisin’s commitment to innovation encourages consumers to explore vehicle seating modifications that align with modern automotive advancements.

TS Tech Co.

Founded in 1960 in Japan, TS Tech Co. Ltd. is a renowned automotive seat manufacturer headquartered in Asaka.

The company’s dedication to delivering comfortable, high-quality products at reasonable prices has fostered a loyal customer base.

TS Tech enhances its offerings, catering to various vehicle types and seating arrangements.

The company’s continuous efforts to balance aesthetics, functionality, and safety drive consumers to seek modifications that reflect their preferences and contribute to an enhanced driving experience.

Harita Seating Systems

Harita Seating Systems is an Indian automotive seat manufacturer known for its innovative and comfortable seating solutions.

With a commitment to technology and quality, the company manufacturing processes to enhance the ergonomic features of their seats.

This dedication to combining technology and comfort motivates consumers to explore modifications to their vehicle seating, ensuring a more enjoyable and safe driving experience.

Grammer AG

Grammer AG is a German company that specializes in developing and manufacturing seating solutions for various vehicles.

The company’s manufacturing processes ensures that their products are not only aesthetically pleasing but also engineered for optimal comfort and safety.

This technological approach drives consumer interest in modifying vehicle seats to align with the latest advancements in seating technology.

Brose

Brose, a global automotive supplier headquartered in Germany, focuses on various automotive components, including seats.

Brose aims to create seats that provide superior comfort, adaptability, and safety.

This commitment to technological excellence encourages consumers to consider modifying their vehicle seating to enjoy the benefits of cutting-edge automotive advancements.

Faurecia

Faurecia, a prominent automotive technology company based in France, specializes in seating solutions and interior systems.

Faurecia creates seats that not only enhance driving comfort but also contribute to a sustainable and connected driving experience.

This focus on technology-driven comfort and sustainability motivates consumers to explore seat modifications that align with the evolving automotive landscape.

Magna International Inc

Magna is a Canadian mobility technology company that designs and manufactures a wide range of automotive components, including seating systems.

With a strong emphasis on innovation and technology, Magna develop advanced seating solutions that prioritize safety, comfort, and customization.

This commitment to technological advancement encourages consumers to consider modifying their vehicle seating to enjoy the benefits of Magna’s cutting-edge solutions.

Gentherm

Gentherm, headquartered in the USA, specializes in thermal management technologies, including heated and cooled seats.

Gentherm creates seats that provide personalized comfort to passengers.

This technological approach motivates consumers to modify their vehicle seats, seeking the luxury and comfort of temperature-controlled seating solutions.

Recaro

Recaro is a German company renowned for its high-performance automotive seating. Combining technology, ergonomic design, and safety, Recaro seats are often preferred by automotive enthusiasts and performance-oriented drivers.

The company’s dedication to seat engineering encourages consumers to explore modifications that align with their driving style and performance preferences.

Leggett & Platt

Leggett & Platt, based in the USA, is a diversified manufacturing company that produces various products, including automotive seating components.

Leggett & Platt creates seating solutions that prioritize comfort, durability, and customization.

This approach motivates consumers to consider seat modifications that cater to their specific needs and preferences.

Bharat Seats

Bharat Seats, an Indian company, specializes in manufacturing automotive seating solutions.

Bharat Seats produces comfortable and aesthetically pleasing seats that align with modern automotive trends.

This technological focus encourages consumers to explore seat modifications that enhance the overall look and feel of their vehicles.

Bridgewater Interiors

Bridgewater Interiors, based in the USA, is a joint venture between Adient and Epsilon Technologies.

The company specializes in manufacturing seating systems and interior components.

Bridgewater Interiors creates seats that prioritize comfort, innovation, and customization.

This technological approach motivates consumers to explore seat modifications that reflect their individual preferences and contribute to an enhanced driving experience.

The Future of Car Seat Manufacturing

Advancements in machine learning and AI algorithms are revolutionizing the future of car seat manufacturing through AI-powered quality inspection.

This technology offers numerous benefits for top car seat manufacturers, including improved efficiency, cost savings, and enhanced quality control.

By automating the inspection process, AI algorithms can detect defects with exceptional precision and speed, surpassing the capabilities of human inspection.

This not only reduces the time required for inspection but also eliminates human errors and bottlenecks.

With AI-powered quality inspection, car seat manufacturers can achieve significant cost savings, increase productivity, and maintain uncompromising quality standards.

Furthermore, the integration of IoT for real-time monitoring and predictive maintenance, as well as the adoption of robotics for automated inspection processes, will further enhance the future of car seat manufacturing.

Conclusion

In conclusion, it is clear that embracing AI-powered quality inspection in car seat manufacturing can bring numerous benefits to top car seat manufacturers.

With the need for enhanced quality control in the industry, AI technology offers a solution to improve efficiency and reduce defects.

While some may argue that implementing AI could lead to job losses, it is important to note that AI can enhance human capabilities, leading to more accurate and reliable inspections.

By leveraging AI, car seat manufacturers can ensure higher quality products and maintain their competitive edge in the market.

Unlock Your Business Potential With AI!

Book a consultation with our expert and discover tailored solutions to boost your business success. Don’t miss out on this opportunity to gain personalized insights and strategies.

Gediminas Mickus

Business Development Manager

Limited seats available - Act now!