The lumber industry is undergoing a significant transformation. AI Quality Inspection of Lumber is changing how lumber quality is being inspected. It offers speed, accuracy, and cost savings.

As demand for high-quality lumber grows, efficient inspection methods become even more critical. This article will explore AI quality inspection. It will cover its benefits, challenges, implementation, and future prospects.

Key Takeaways

- Advanced AI solutions: AI quality inspection brings significant improvements in speed. It also boosts accuracy and leads to cost savings when compared to traditional methods.

- Customer satisfaction: AI ensures reliable defect detection. This enhances customer satisfaction and helps secure long-term client relationships.

- Operational Efficiency Gains: AI operates continuously without fatigue. This enables faster production lines and more efficient operations.

- Adaptable to Market Demands: AI-based inspection systems continuously learn and adapt. They are versatile for evolving industry standards and customer requirements.

- Future Growth and Integration: The adoption rate of AI in the lumber industry is increasing steadily. Future advancements will make systems even more efficient.

Understanding AI Quality Inspection of Lumber

Artificial Intelligence (AI) in lumber inspection is revolutionizing quality assessment. Traditionally, wood inspection was done manually. It involved experts checking each piece for defects.

These included knots, cracks, discoloration and other defects. However, manual inspection has limitations, including human error and slow processing. AI Quality Inspection of Lumber provides an advanced alternative.

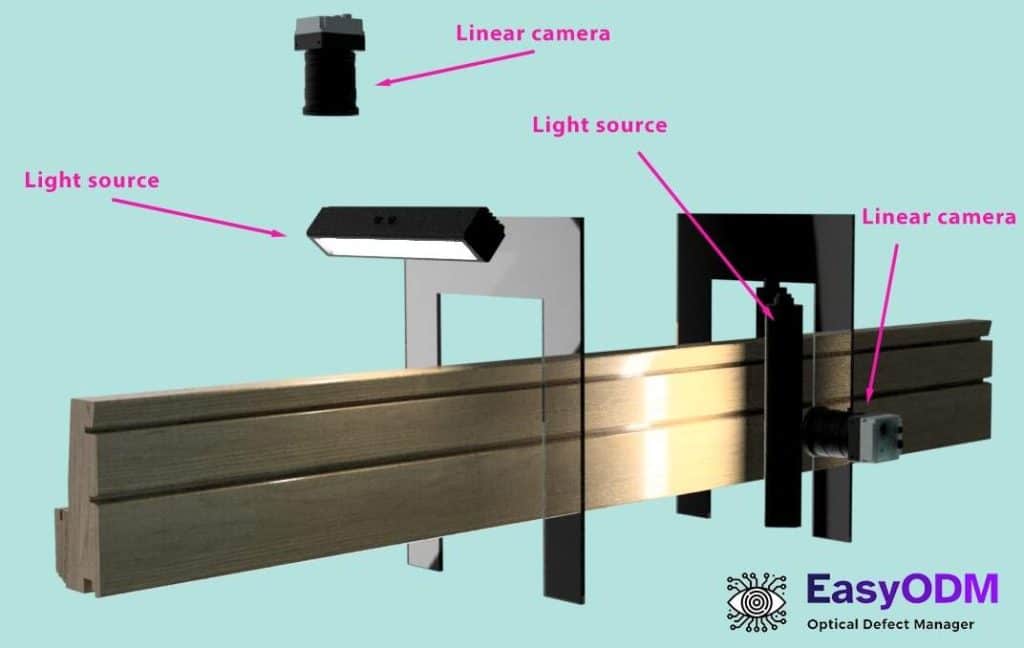

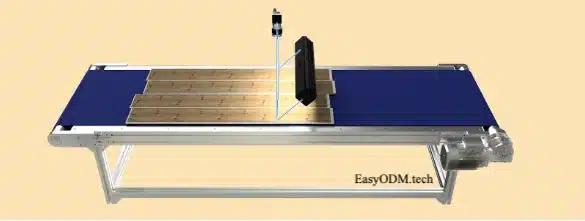

AI leverages machine learning, imaging, and sensors. It evaluates lumber with speed and accuracy. These systems analyze each piece to detect defects and measure critical dimensions. This ensures high-quality lumber reaches customers.

How Does AI Quality Inspection Work?

AI quality inspection systems use cameras and sensors to collect data on lumber. This data includes dimensions, moisture content, and surface conditions. Machine learning algorithms then analyze the data in real-time. They identify defects like knots, cracks, and discolorations. The findings are compared to quality standards to grade each piece during the AI quality inspection of lumber.

Despite breakthroughs in AI quality inspection, many companies still rely on manual inspection. Manual hardwood lumber grading involves identifying defects, calculating usable areas, and measuring dimensions. In real production settings, human accuracy ranges from 48% to 75%. This is due to factors like production speed, complex calculations, and fatigue. AI quality inspection of lumber offers greater consistency. It significantly enhances grading accuracy and efficiency compared to manual methods.

Benefits of AI Quality Inspection of Lumber

Adaptable to Market Demands

AI-based inspection systems continuously learn and adapt. This makes them versatile to evolving industry standards and customer requirements.

Sustainable Use

By reducing waste through precise defect detection, AI promotes sustainable wood use. It enhances quality and contributes to a positive market impact.

Increased Efficiency

AI quality inspection of lumber accelerates the assessment process. It allows production lines to move faster and handle more volume. Unlike human inspectors, AI is not limited by fatigue. It works continuously, reducing evaluation time and enabling smoother, faster operations.

Improved Accuracy

AI inspection offers high precision. It detects even small defects that humans may overlook. AI ensures more consistent quality, which improves product standards and reduces waste.

Cost Savings

Despite the initial costs, AI quality inspection of lumber reduces labor expenses and human errors. This results in fewer rejected shipments and returns. Continuous operation without breaks leads to better resource use and increased profitability.

Enhanced Safety

AI reduces the need for direct human contact with heavy or sharp materials. This minimizes injury risks. Workers can focus on safer tasks, lowering injury rates and boosting job satisfaction.

Increased Customer Confidence

AI quality inspection of lumber increases reliability and consistency. Consequently, this maintains high customer satisfaction and market competitiveness. This reliability helps companies maintain better client relationships. It also secures long-term contracts and boosts buyer confidence in lumber products.

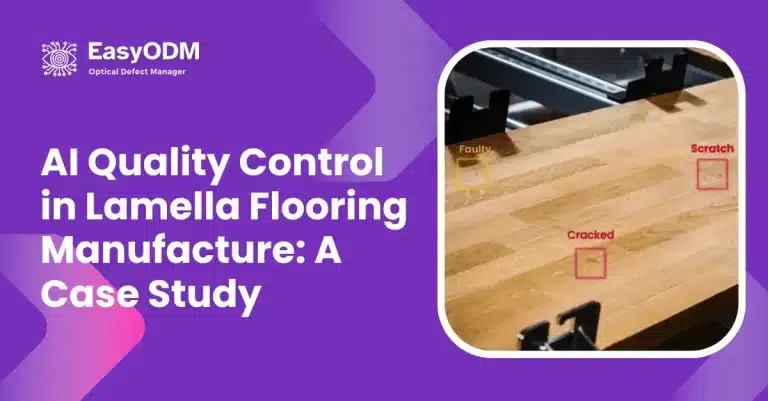

EasyODM’s AI Solutions for the Wood Industry

At EasyODM, we provide AI-based solutions tailored for the wood industry. These solutions boost operational efficiency and quality control. Our machine vision software excels at detecting a wide range of defects. Among other things, these include cracks, chipped areas, live knots, grain irregularities, decay, and insect damage.

Our solutions offers unmatched objectivity, fatigue-free performance, and consistent reliability. EasyODM enhances safety in challenging environments. It ensures precise adherence to quality standards, ensuring optimal wood quality control.

Challenges in Implementing AI Inspection

Initial Investment Requirements

Implementing AI inspection systems involves costs for hardware, software, installation, and integration. These costs can be significant. However, careful financial planning can make adoption feasible for all companies.

Need for Skilled Labor

Operating AI equipment requires technicians who understand both the machinery and AI algorithms. Training staff or hiring skilled workers adds to costs.

Resistance to Change

Employees may fear job loss, leading to resistance during AI implementation. Educating workers on AI’s benefits can help overcome these concerns. These benefits include improved safety and job shifts to more advanced roles.

Maintenance and Upgrades

AI quality inspection of lumber systems need regular maintenance and software updates. This is essential for optimal performance. Neglecting updates can lead to inefficiencies or system failures.

Overcoming Implementation Challenges

Industry Adoption Rates

Only 30-40% of producers currently use AI inspection. However, AI adoption in the lumber industry is growing. Adoption is expected to rise even more in the upcoming years. Companies are seeking the benefits of improved efficiency, accuracy, and cost savings. This is crucial for them to stay competitive.

Financial Planning

Companies can use leasing or financing to spread out the investment. Treating AI as a long-term investment helps make costs manageable. This is especially true when considering future savings. For detailed cost analysis we offer our ROI calculator.

Training Programs

Employee training is key to AI success. Training can be done in-house or with external experts. This ensures workers are well-prepared to keep AI systems running smoothly.

Ongoing Support

Partnering with AI providers for regular maintenance and support ensures effective system operation. Quick troubleshooting helps minimize production disruptions.

The Future of AI Quality Inspection of Lumber

Enhanced Sensor Technology

Future improvements in AI quality inspection focus on advancing sensor technologies. Newer sensors, such as new tier near-infrared lasers and high-resolution cameras, will help in detecting issues.

These include iron stains, subtle cracks, and pale knots. Improved pith recognition technology will also be integrated. This will be based on analyzing the thickness map. It will help correctly identify and process defects like pith.

(Source)

New sensors and hardware, are only the beginning of AI Quality Inspection of Lumber. Future AI advancements will elevate the industry even further:

- Predictive Maintenance: AI will anticipate machinery maintenance needs. This will reduce downtime and improve overall efficiency.

- Supply Chain Automation: AI is going to fully integrate in the supply chain management. This will therefore enhance real-time inventory tracking, and will streamline production flow.

- Enhanced Analytics: AI will offer deeper insights into production trends. This will enable better and faster decision-making.

- Robotic Handling Systems: Combining AI with robotics will drive full automation of lumber processing. This will significantly increase speed, reduce labor costs, and transform workflows.

Conclusion

AI Quality Inspection of Lumber is transforming the industry. It makes inspection faster, more precise, and safer. Despite the challenges, the long-term benefits make AI essential for modern lumber manufacturers.

As technology evolves, those who embrace AI advancements will have a competitive edge. The future of lumber inspection is here. Companies that invest in AI today will reap the rewards. These rewards include improved quality, efficiency, and profitability.