Artificial Intelligence (AI) is changing the pharmaceutical industry. This change is especially clear in manufacturing. From drug formulation to quality assurance, AI in pharmaceutical manufacturing is making processes smarter. It’s also making them faster and more reliable.

Key Takeaways

- Data-Driven Decision Making: AI helps optimize production schedules and resource allocation. This makes manufacturing more efficient and reduces waste.

- Proactive Maintenance: AI predicts equipment failures before they happen. This reduces downtime and keeps production running smoothly.

- Regulatory Compliance Support: AI helps automate compliance documentation and checks. It makes meeting regulatory standards easier.

- Real-Time Process Adjustments: AI allows for quick tweaks to production parameters. This maintains consistent product quality and efficiency.

- Continuous Improvement: Machine learning models keep getting better. They improve quality control over time by learning from new data.

What is AI in Pharmaceutical Manufacturing?

AI in pharmaceutical manufacturing means using advanced algorithms and machine learning. These technologies help optimize drug production.

AI in pharmaceutical manufacturing also allows for automated adjustments to manufacturing workflows, ensuring consistency and efficiency. It can also predict outcomes with high accuracy. It ensures quality and reduces waste.

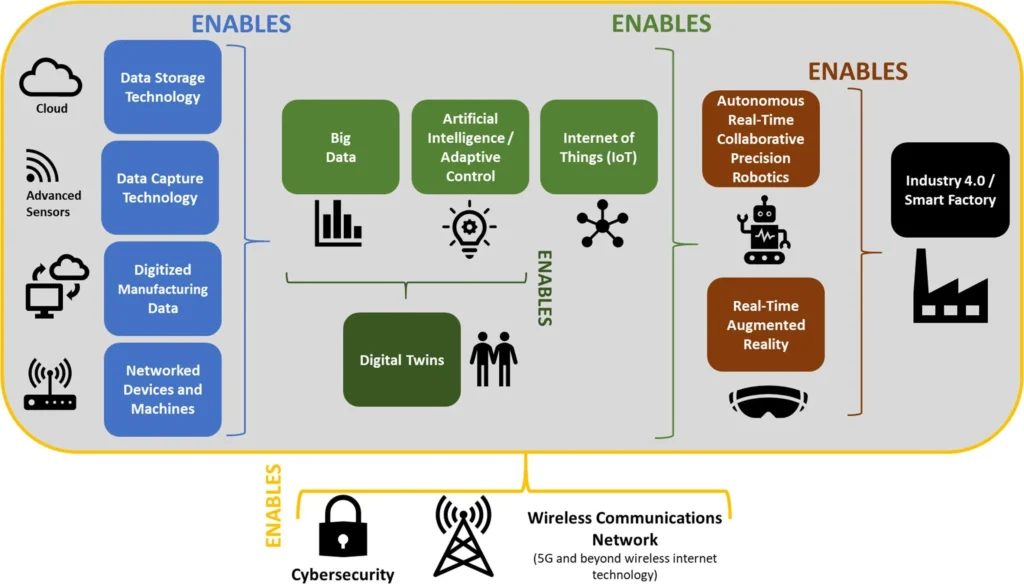

Industry 4.0, also known as the fourth industrial revolution, is making big changes in pharmaceutical manufacturing. This study talks about the combination of AI, the Internet of Things (IoT), robotics, and advanced computing.

Together, these technologies create a smart, self-managing production environment. This setup improves efficiency, flexibility, and product quality. With Industry 4.0, AI goes beyond collecting data. It turns data into useful insights for automated decision-making.

Benefits of AI in Pharmaceutical Manufacturing

Quality Control with AI

Quality control is very important in pharmaceutical manufacturing. AI in pharmaceutical manufacturing is making it much more efficient. With computer vision, a type of AI, flaws in products are found faster and more accurately than with manual checks.

Machine learning also helps AI systems get smarter over time. These systems learn from past data and keep improving. This makes quality checks more reliable and ensures even small issues are detected.

A recent study shows that AI also uses advanced data analytics to support real-time decisions and adjustments. It collects data from equipment, sensors, and quality control systems. This gives a complete view of the manufacturing process. As a result, every batch of medicine meets strict quality control standards.

EasyODM’s Solutions for Pharmaceutical/medical industry

EasyODM provides specialized machine vision software for the pharmaceutical industry. It helps improve quality control by finding pill defects quickly. Using advanced machine learning, EasyODM spots cracks, faulty engravings, and scratches.

This ensures that patients receive only top-quality medication. This automated inspection is precise, works non-stop, and delivers consistent results for manufacturers.

Medical device manufacturing

Data Management and Compliance

AI is also crucial for following Good Practice (GxP) guidelines. Pharmaceutical manufacturing creates large amounts of data. This includes production records and quality control details. AI in pharmaceutical manufacturing helps organize, analyze, and maintain this data.

Automating data collection and analysis reduces human error, which is key for compliance. Machine learning also monitors production in real-time. It quickly spots any deviations from standards to keep everything as it should be.

AI’s Assistance with Decision-Making in Pharmaceutical Manufacturing

AI also improves decision-making by turning complex data into clear insights. It helps manufacturers make decisions faster. AI can adjust production schedules, reallocate resources, or change factors like temperature and humidity. AI also identifies which quality control steps need the most attention.

These data-driven decisions keep operations efficient and ensure high product quality. Additionally, AI boosts security by automating compliance checks and monitoring operational integrity. It catches security threats in real time, keeping data and systems safe.

Predictive Maintenance and AI

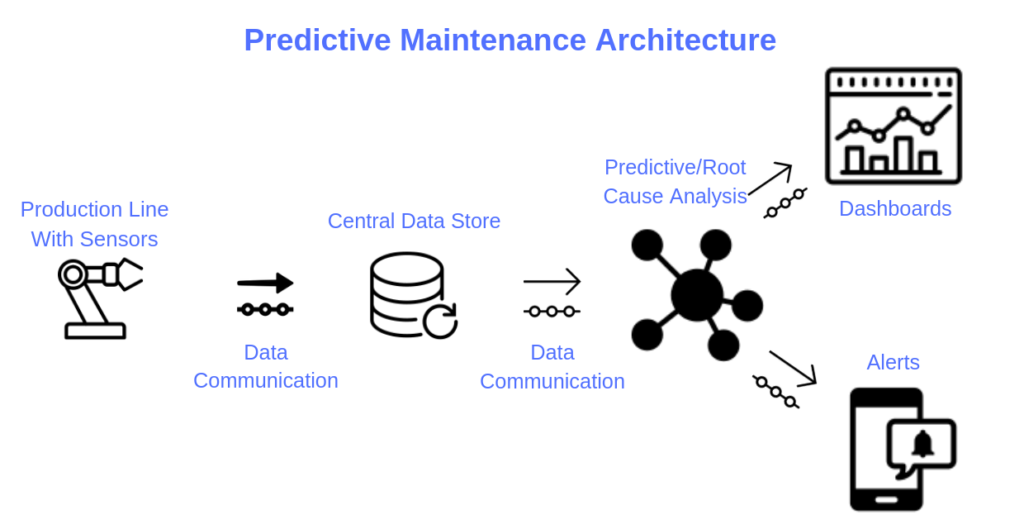

AI plays a big role in keeping machines running smoothly. In pharmaceutical production, machines need to work at full capacity to avoid delays. When a machine breaks down, everything slows down.

AI helps predict when equipment might fail. This means breakdowns can be prevented before they happen. This helps keep operations running with fewer interruptions.

AI looks at machine data and finds potential issues before they become actual problems. This saves time and cuts costs. AI in pharmaceutical manufacturing streamlines maintenance schedules, reducing machine downtime and keeping production lines active.

This creates a more efficient manufacturing environment. There is less downtime and more focus on producing quality products.

AI in Drug Formulation and R&D

AI is also helping in drug formulation. The research and development (R&D) phase in pharmaceuticals is complex. Developing a new drug can take years. AI algorithms help by predicting the best formulations.

They analyze the molecular structure of compounds. They also simulate how these compounds might work in the human body. AI can narrow down the number of tests needed, which reduces the time for R&D.

Challenges of Using AI in Pharmaceutical Manufacturing

While AI offers many benefits, it also brings challenges. One major hurdle is data quality. AI systems need large amounts of high-quality data. If the data is flawed, the AI’s predictions will be wrong. The pharmaceutical industry must ensure data integrity at all stages.

Integrating AI into pharmaceutical manufacturing can be challenging. AI needs specialized skills, so staff must be trained. This can be costly and time-consuming. The initial cost of adopting AI can also be high. It often involves upgrading old systems and changing how things are done.

Infrastructure upgrades, like network improvements and better cybersecurity, are also needed. Meeting regulatory standards adds even more complexity. Despite these challenges, the long-term benefits, such as improved efficiency and cost savings, make the investment worth it.

The Future of AI in Pharmaceutical Manufacturing

The future of AI in pharmaceutical manufacturing looks bright. AI will keep advancing and expanding beyond current uses. We can expect AI to play more roles in R&D, quality control, and logistics.

As more companies adopt AI, the industry will see faster production cycles. Drugs will be developed and made more efficiently. AI in pharmaceutical manufacturing can also make the production process more adaptable to changing demands, enhancing responsiveness. This can lower production costs and make medicines more affordable for consumers.

AI-driven automation will go beyond regular production tasks. It will involve more real-time adjustments and automated quality control, which, in turn, will increase production consistency and quality further.

Conclusion

AI in pharmaceutical manufacturing isn’t just a trend. It’s a game-changing solution that addresses many industry challenges. From quality control to predictive maintenance, AI is changing how drugs are produced.

Sure, there are still challenges, but the benefits are too substantial to ignore. As technology advances, AI’s role in pharmaceutical manufacturing will keep growing. Adopting AI is crucial for the industry to keep improving.