Aerospace manufacturing with AI is evolving, with AI playing a critical role. The industry relies on precision, safety, and quality. AI helps meet these requirements while improving efficiency. AI has transformed many aspects of aerospace, from design to production. Its ability to process data quickly is central to these improvements.

By integrating AI, aerospace manufacturers are addressing challenges like quality control and safety. AI allows them to handle complex designs and streamline processes. The result is faster production with fewer errors.

Key Takeaways

- Industry transformation. Aerospace manufacturing with AI is revolutionizing the industry. It enhances efficiency, quality, and safety across the industry.

- Faster design processes. Design processes benefit greatly from AI’s ability to analyze data quickly. This leads to innovative solutions and significant time savings.

- Defect detection accuracy. Quality control is more effective with AI-driven automated inspections. These systems reduce human error and improve accuracy in detecting defects.

- Streamlined operations. AI enhances factory automation, streamlining operations and optimizing supply chain management. This results in faster production and cost savings.

- Promising future. The future of aerospace manufacturing with AI looks promising. Continued advancements will lead to safer and more efficient aircraft.

Enhancing Design with AI

One of the most significant impacts of AI is in aerospace design. AI tools allow engineers to explore innovative designs and optimize configurations. AI helps reduce the weight of aircraft while improving their strength and efficiency. This is particularly important in fuel consumption optimization.

AI also accelerates the design process. In traditional methods, predictive analytics took a long time to provide useful feedback. With AI, design simulations now happen much faster. Engineers can test multiple scenarios within minutes rather than hours.

For example, collaborations between AI developers and aerospace companies have dramatically reduced the time required for design predictions. This collaboration has led to increased efficiency. AI helps engineers create optimized solutions more quickly. This results in cost and time savings.

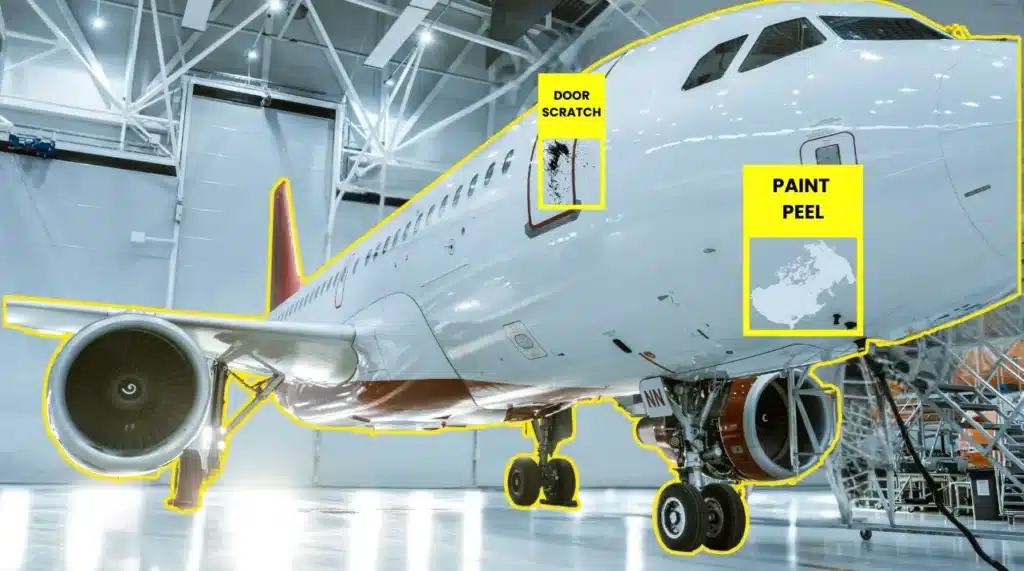

AI and Quality Control in Aerospace

Quality control is critical in aerospace manufacturing with AI. Every part must meet strict standards. AI ensures this by automating the inspection process. Machine learning algorithms scan components for defects, such as cracks or irregularities.

Automated inspections not only detect issues earlier but also improve accuracy. This reduces the reliance on human inspectors, lowering the risk of errors. AI systems are capable of processing huge amounts of data quickly. They can analyze images and detect even the smallest issues.

AI also provides real-time data analysis, allowing manufacturers to monitor production lines continuously. This ensures that parts and products meet quality standards throughout the manufacturing process.

Case study: Aircraft electrical harness manufacturing

One practical example of AI’s capabilities is the case of electrical harness manufacturing. This case study’s methodology focuses on error prediction and risk mitigation to prevent failures and their consequences. Results from a military aircraft electrical harness manufacturing showed a 93% time reduction and 90% error reduction when using AI in engineering and manufacturing processes.

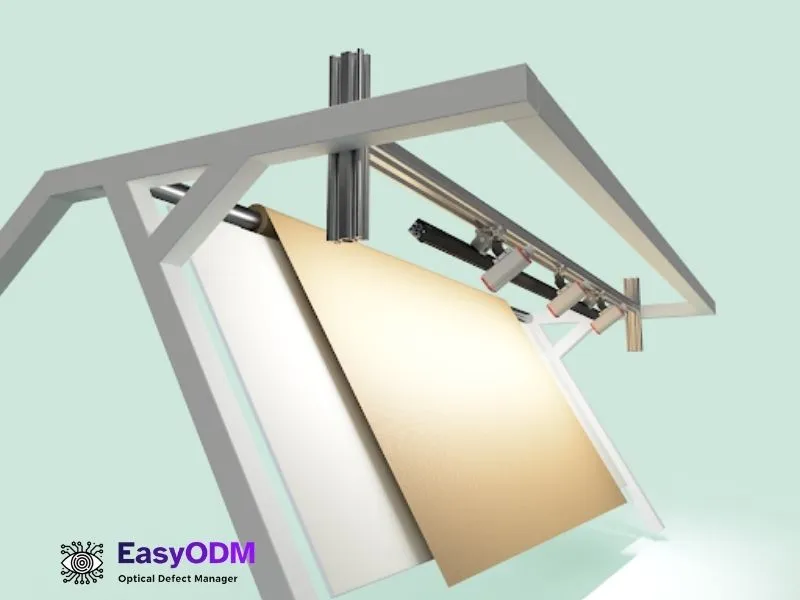

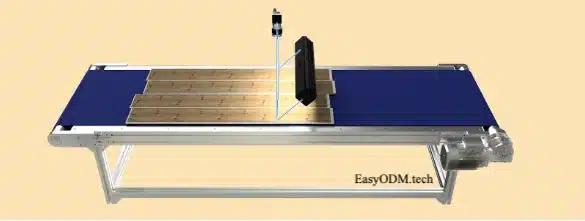

EasyODM’s Role in Quality Control

In addition to aerospace manufacturing, AI’s impact extends to overall manufacturing quality control. EasyODM plays a vital role in this broader context. Its advanced machine vision system ensures thorough inspection for defects. This leads to superior quality. The software provides unbiased and objective results, free from human error. This leads to consistent performance and enhances operational safety in various environments.

Factory Automation with AI

AI-driven factory automation has revolutionized aerospace production. Automated systems handle tasks like drilling, fastening, and welding with greater precision than ever before. These systems improve efficiency and reduce errors. AI can monitor machine performance and optimize operations. This results in increased efficiency.

AI Enhances Supply Chain Management

In addition, AI enhances supply chain management. By analyzing data, AI predicts demand and identifies the best suppliers. It also helps manage inventory, ensuring that parts are available when needed. This prevents delays and streamlines production processes.

Factory automation leads to significant time and cost savings. Manufacturers can produce high-quality components faster, boosting productivity.

Safety and Reliability in Aerospace Manufacturing

Safety is a top concern in aerospace, and AI helps maintain it. AI-powered systems provide real-time insights into production processes. This ensures safety protocols are followed, and potential risks are addressed early. By predicting issues before they happen, AI enhances reliability across the board.

AI also plays a role in autonomous systems like autopilot technologies. These systems can handle complex tasks like takeoff, navigation, and landing. AI autopilot systems are already being used in commercial jets and drones. These systems improve safety by making precise adjustments during critical flight stages.

In addition, AI assists in cybersecurity by detecting abnormal patterns in data. This is especially important as aerospace systems become more digitalized. Protecting against cyber threats ensures the safety and security of both aircraft and defense systems.

Predictive Maintenance impact on aerospace manufacturing

In aerospace manufacturing, predictive maintenance plays a critical role in keeping aircraft systems running smoothly. AI-powered predictive maintenance systems analyze data from aircraft components to forecast when maintenance will be required. This approach prevents unexpected breakdowns, reduces unplanned downtime, and prolongs the life of equipment.

By predicting issues before they happen, predictive maintenance ensures aircraft are serviced during planned periods, not when something fails. This not only improves safety but also allows for smoother operations and flight schedules, leading to greater efficiency across aerospace manufacturing.

The Future of Aerospace Manufacturing with AI

Aerospace manufacturing with AI is set to continue shaping the future of aerospace manufacturing. Its applications in design, quality control, and safety will expand. The use of AI-driven automation will improve production speed and product quality. Companies that adopt AI will have a competitive edge.

As AI evolves, its role in the aerospace industry will become even more significant. Manufacturers will be able to create safer, more efficient aircraft. AI will continue to reduce costs and enhance reliability across the industry. Aerospace manufacturing with AI is driving the next generation of innovation and progress.

Conclusion

Aerospace manufacturing with AI is revolutionizing the industry. It enhances design processes, quality control, and overall safety. As manufacturers continue to adopt AI technologies, the benefits will only grow. The future looks promising, with AI driving efficiency, innovation, and reliability.