AI in electronic assembly quality control has become a game changer. Making electronic products is a detailed and careful process. Quality control is very important in this industry. Even small mistakes can lead to problems or safety risks.

Older quality control methods are slow, expensive, and often have errors. AI, or artificial intelligence, is changing quality control in electronic assembly. It makes the process faster, more accurate, and more efficient.

Key Takeaways

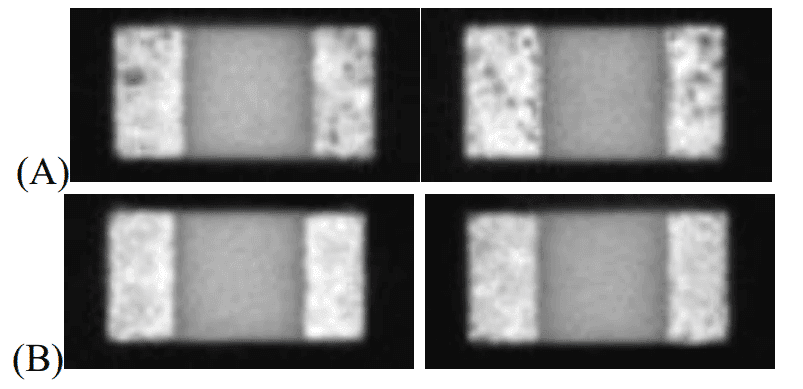

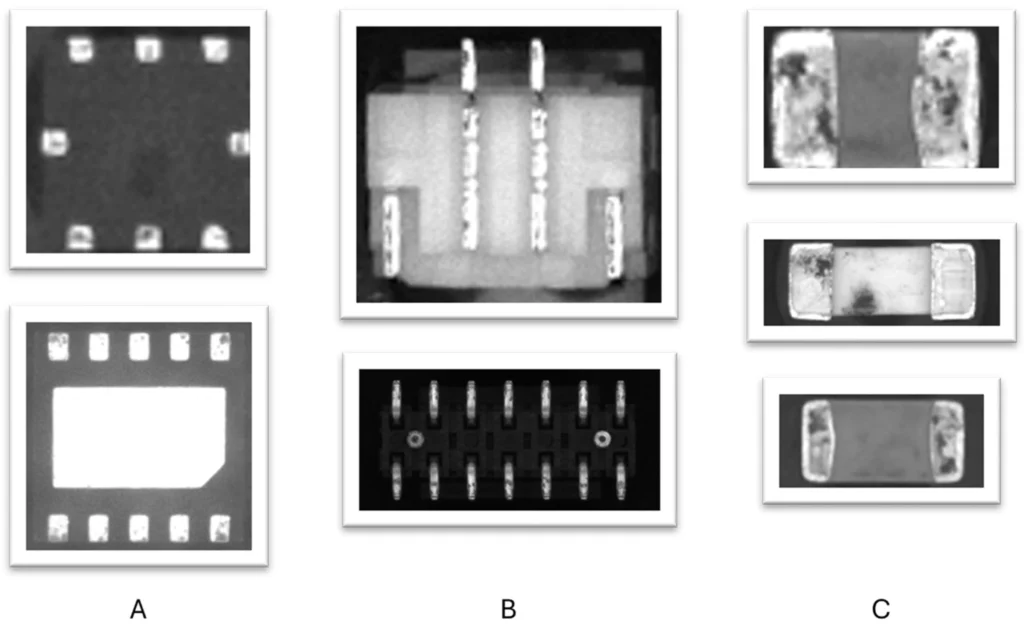

- Better Solder Quality: AI in electronic assembly quality control improves soldering and helps prevent failures. It checks for issues like gaps or bad coverage.

- Quick Defect Sorting: AI finds and sorts defects with very high speed. This helps to quickly make quality control decisions about fixing or removing parts.

- Predicting Problems: AI analyzes data to predict future issues. This helps solve problems before they happen.

- Tracking Parts: AI keeps track of every part during assembly. This helps manage and identify parts at risk if there is a defect.

- Growing with Production: AI can expand as production needs grow. It keeps quality consistent even as demands increase.

How AI Improves Quality Control

AI in electronic assembly quality control systems check parts quickly and accurately. Human inspectors get tired and can miss small spots. AI works non-stop without taking breaks. This means every part gets checked at the same level of standard.

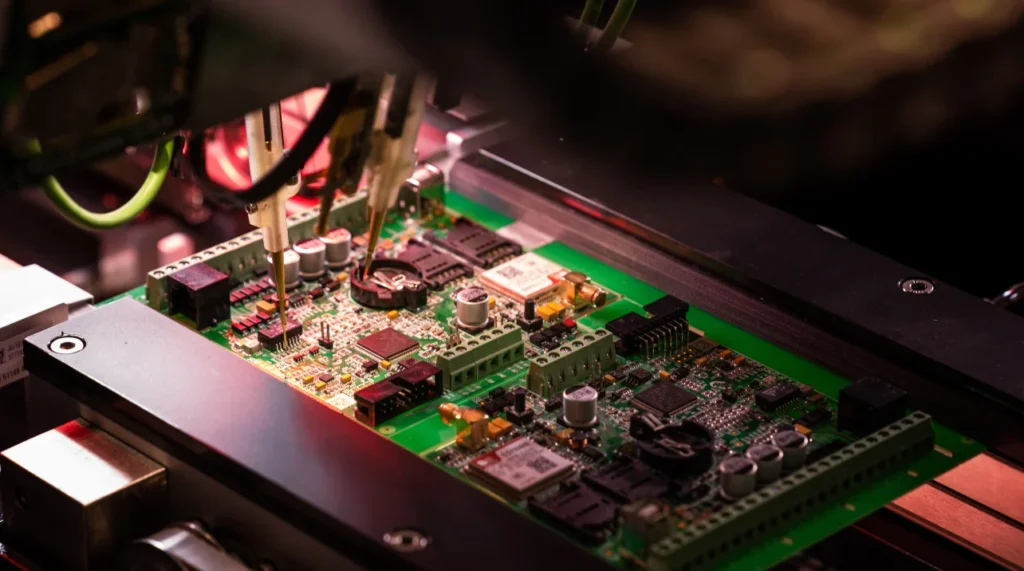

AI in electronic assembly quality control finds errors like cracks or bad soldering that people might miss. It uses computer vision and machine vision software to look at circuits and parts on the assembly line. AI can easily tell good products from faulty ones.

Car part case study

One example of AI’s ability was in a car part production line. AI detected issues like corrosion or mold in soldering joints. It used cameras to take pictures in real-time. It flagged any parts that had defects, making sure only good parts moved forward.

Better Product Quality and Standards

AI in electronic assembly quality control helps improve the quality of products by catching more errors. It checks for even the smallest flaws. This means products are less likely to fail, which, of course, makes customers happier. AI also helps companies follow strict quality rules. It makes sure that the products meet standards, like IPC-A-610 and IPC-J-STD-001.

Steps AI Takes in Quality Control

AI follows several important steps to keep quality high:

- Data Collection: AI in electronic assembly quality control takes pictures and collects data from many points along the assembly line.

- Data Analysis: AI analyzes this data immediately. It looks for issues like misalignments, cracks, as well as other defects in real-time.

- Defect Classification: AI sorts the defects by type and seriousness. This helps decide if a part needs rework or should be rejected.

- Make Decisions: Based on the type of defect, AI decides if parts should be fixed or removed from the production line altogether.

- Adjustments: AI diagnose and suggest changes to machines or processes to stop the same problems from happening again. This keeps quality improving over time.

Saving Costs with Automation

Finding problems early reduces the need for costly repairs and cuts down on wasted materials. AI also lowers labor costs. Fewer workers are needed for inspection, so they can do more important jobs.

For example, using AI in electronic assembly quality control has reduced the number of defects per million parts. In one case, AI found oxidation problems on parts early in the process. This improved the overall quality and reliability of the products.

AI Predicting Problems Before They Happen

AI can do more than just find problems right away. It can also use data to predict future issues. AI looks through the data from the assembly line to find patterns that might lead to problems later. This lets companies fix these issues before they become bigger problems.

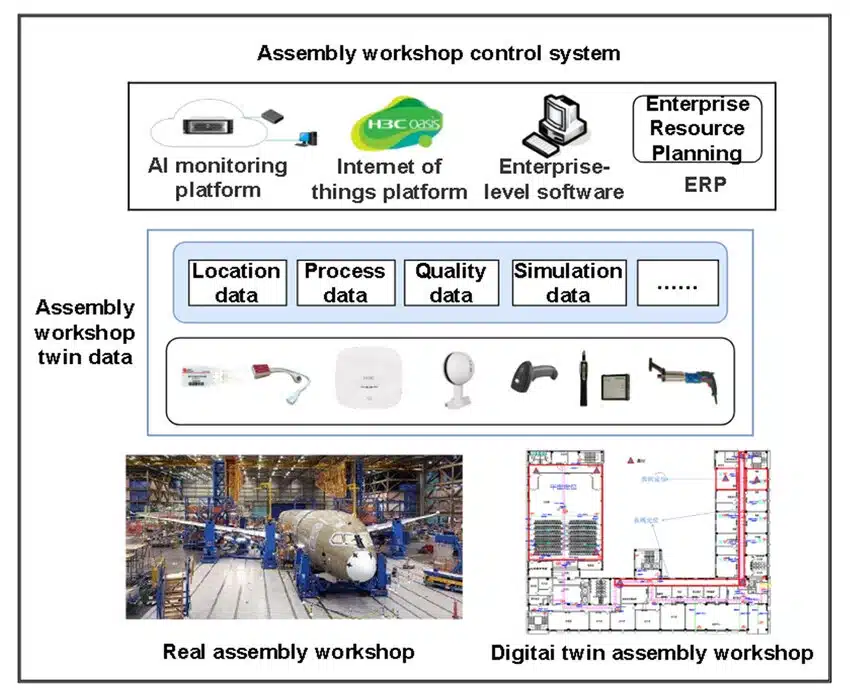

AI in electronic assembly quality control also helps keep track of each part throughout the assembly. This means if there is a problem, it is easier to see which parts might be at risk. Digital twin technology is also used to create a virtual copy of the assembly process. This helps make real-time improvements and catch problems before they get worse.

Flexibility for Growing Production

AI systems are flexible and can grow with production needs. When production needs increase, AI in electronic assembly quality control can expand to inspect more parts without losing quality. This flexibility is important for manufacturers because demand can change quickly. AI makes it easier to increase production while keeping quality high.

Challenges of Using AI

There are some challenges to using AI in quality control. The cost to set up AI systems can sometimes be substantial. It includes buying the necessary hardware and software, as well as training workers. AI also needs good data to work properly.

Poor data can lead to mistakes in the inspection process. Keeping AI systems running well requires regular maintenance. There can also be concerns among workers about losing their jobs. It is important to provide training and help them adapt to the new technology.

The Future of AI in Quality Control

The future of AI in electronic assembly quality control looks promising. As technology keeps improving, AI will become even faster and more accurate. AI combined with IoT (Internet of Things) will allow for real-time quality control. Digital twin technology will also help predict and fix problems before they affect production.

Companies that use AI in electronic assembly quality control will have an advantage over others. They will have fewer defects, lower costs, and better products. Investing in AI today will help companies stay ahead and ensure strong manufacturing in the future.

Conclusion

AI in electronic assembly quality control is changing the industry by making inspections faster, cheaper, and more accurate. It also predicts problems before they happen, helping manufacturers stay ahead.

As technology advances, AI will become even more essential for ensuring quality and efficiency. Companies that use AI will be able to lead in the market and keep quality at its best.