The paper industry is changing. Advances in technology are reshaping how paper is produced and managed. AI in paper industry is at the forefront of these changes.

It’s transforming manufacturing, quality control, and distribution. This shift increases efficiency and improves quality. It also helps with sustainability practices.

Key takeaways:

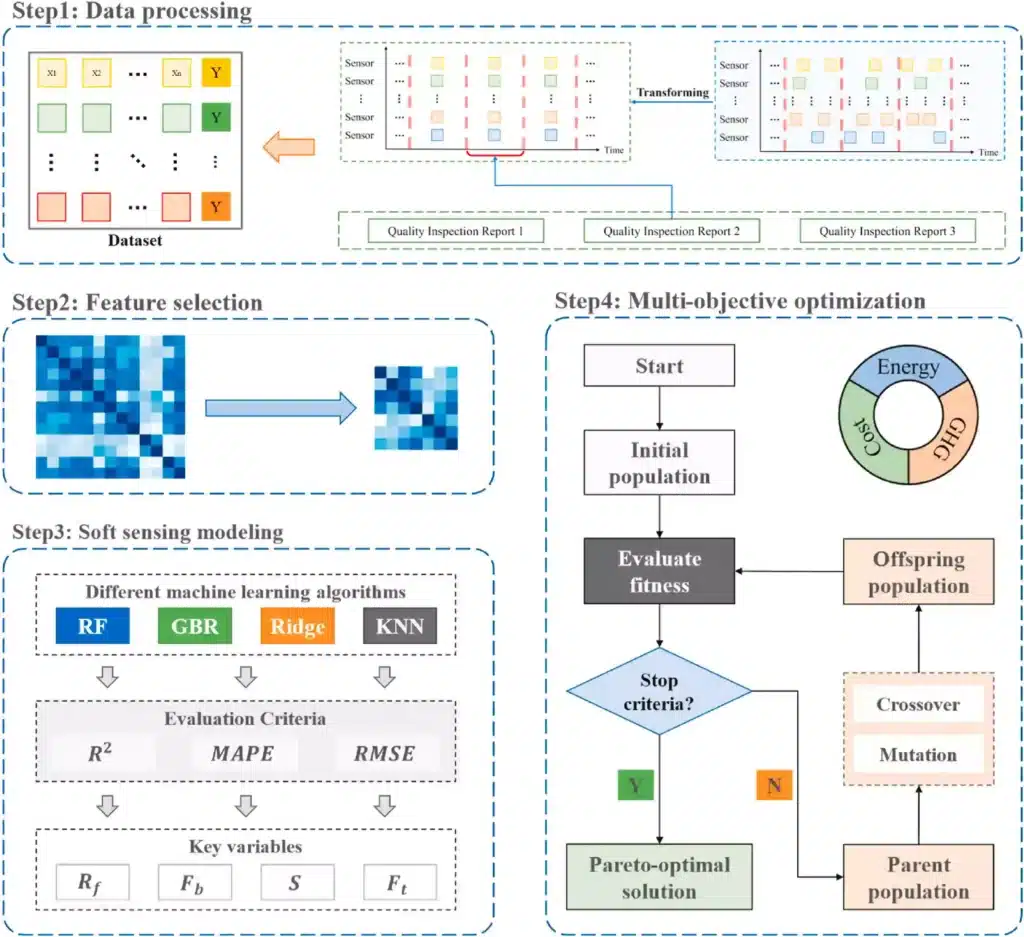

- Soft sensors: AI-driven soft sensors predict quality parameters like folding endurance. These sensors reduce the need for destructive testing.

- Intelligent digital twin systems: These systems predict key variables like stirring speed. This helps to optimize energy usage and efficiency.

- Efficient Chemical Usage: AI helps optimize the use of chemicals. This reduces chemical waste and prevents contamination of wastewater.

- Pareto front: Using pareto front analysis, AI systems are able to balance energy, emissions, and costs. This helps achieve a 17.3% reduction in energy usage.

- Safety in production: AI-powered robots handle dangerous tasks in production. This significantly improves worker safety and reduces accident risks.

The Role of AI in Paper Industry’s Production

AI in paper industry is key in improving the paper production process. It helps monitor raw materials and reduces waste.

AI-based systems predict the right amount of raw material needed. This prevents overproduction and leftover waste. As a result, costs drop, and sustainability improves.

Maintenance

Machine learning algorithms predict machinery issues before they happen. Predictive maintenance helps reduce unexpected downtime. Less downtime means factories run smoothly without costly interruptions. This improves productivity in the paper industry.

Quality sensors

AI in paper industry utilizes AI-driven soft sensors to predict quality parameters like folding endurance, bursting strength, and smoothness. These sensors work without destructive testing and replace physical ones. This reduces costs, improves energy efficiency, and ensures better production quality.

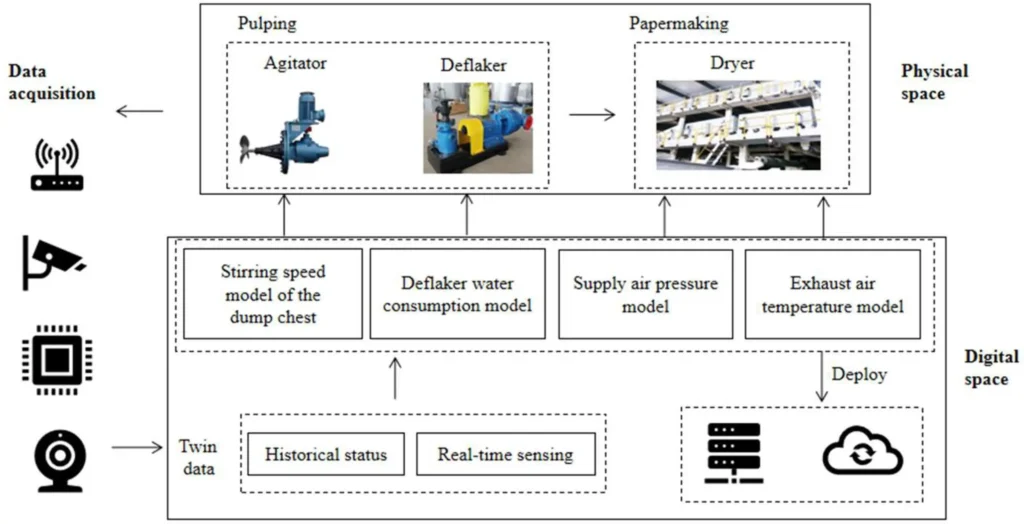

Digital twin

AI in paper industry also creates digital models of physical systems. These models help simulate and optimize production. The intelligent digital twin system (IDTS) uses AI to predict key variables. These include stirring speed, water use, air pressure, and exhaust temperature. These predictions help cut energy use and improve efficiency.

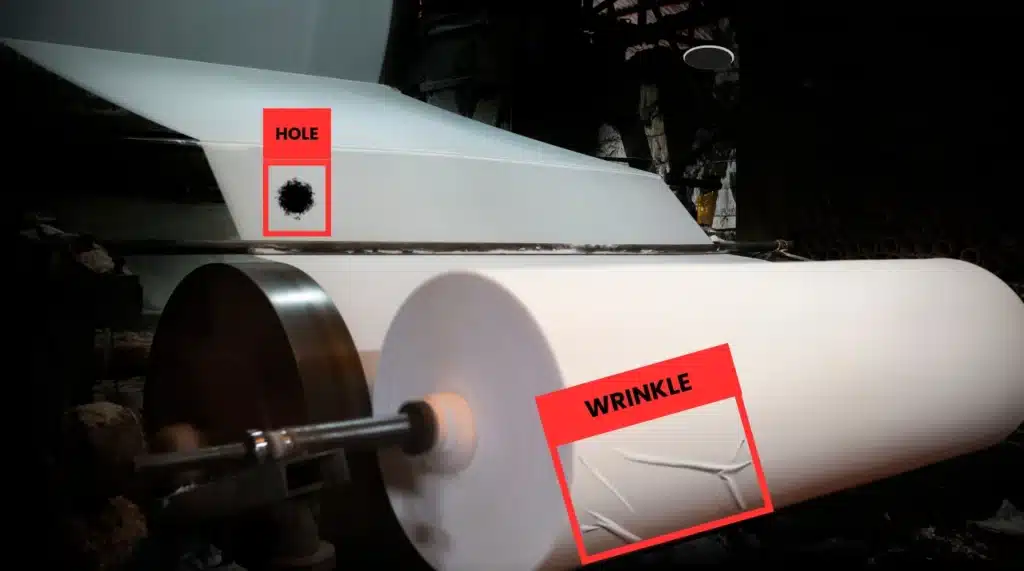

Quality Control with AI

AI plays a crucial role in maintaining quality in the paper industry. It inspects paper for defects at every stage using cameras, sensors, and machine learning.

Machine vision detects surface defects like tears more accurately than human eyes, operating non-stop to inspect thousands of sheets per hour. The data collected is analyzed in real-time for immediate corrections.

AI also adjusts machine settings to maintain consistency, learning from the relationship between settings and quality. By monitoring parameters like stirring speed, water use, and air pressure, AI ensures quality standards are consistently met.

Sustainability and Efficiency

AI helps optimize energy use and reduce emissions, making AI in paper industry a vital tool for eco-friendly practices. Soft sensors use chemicals efficiently, cutting greenhouse gases. AI tracks production to cut waste and adjust schedules.

Models like random forest (RF) and gradient boosting regression (GBR) balance energy, emissions, and costs. Studies show that AI can reduce costs, energy use, and emissions by up to 17.3%.

This is achieved using methods like Pareto front analysis. AI also helps cut chemical waste. AI ensures the right amount of chemicals are used. This prevents excess from entering wastewater.

Tracking production data helps cut waste and adjust schedules. These models support sustainability by managing energy, emissions, and costs.

Improved Worker Safety

AI is making the paper industry safer for workers. It predicts machine issues and alerts workers before they happen. This helps prevent accidents. AI-powered robots in the paper industry handle dangerous tasks, keeping workers safe from risky situations.

AI in paper industry can also create a virtual environment to simulate different scenarios. This helps with better planning and managing risks. Safety protocols are followed strictly.

Challenges and Solutions

AI implementation can be costly. It requires hardware, software, and training. Smaller manufacturers may struggle with these costs. Many choose AI as a service to lower initial expenses. Workforce training is also crucial. Even though initial costs can be substantial, AI reduces operational expenses and boosts efficiency.

Some companies rent AI capabilities instead of full ownership, lowering costs. Training workers is key to making the most of AI. High investments in sensors and infrastructure are challenging. But lower operational costs and better efficiency make these investments worthwhile. AI as a service also helps smaller manufacturers access advanced technologies.

The Future of AI in the Paper Industry

The future of AI in paper industry looks promising. As technology advances, more automation will happen. Machine learning models will keep improving as they learn from more data. Paper manufacturers will produce more with fewer resources. This will make the industry more sustainable and profitable.

AI may also help create new types of paper products. By understanding market needs better, companies can develop new products. These might include stronger or more eco-friendly paper.

As AI gets better integrated, the paper industry will benefit from real-time adjustments. It will also benefit from predictions. This will drive more efficiency and sustainability. It will also lead to better production processes.

Conclusion

AI in paper industry is more than a trend. It is changing how paper is made, managed, and sold. AI boosts production efficiency, improves quality control, and helps with sustainability. It also makes the workplace safer.

The challenges of cost and training are being addressed, making AI more accessible. Adopting AI is crucial for the paper industry to stay competitive. As AI evolves, its role in the paper industry will grow.

This will lead to higher efficiency, lower costs, and better products for everyone. AI will also enhance production capabilities. It will lead to better quality control, improved sustainability, and optimized resource use. These advancements are key for the industry’s success in a changing world.