The furniture industry is evolving. Technology is changing the way manufacturers approach quality. In the past, inspecting wooden furniture was done manually.

Workers had to check each piece by hand. Therefore this method was prone to human error. That’s where AI-powered furniture quality inspection comes into play. It offers a smarter, faster, and more accurate solution.

What is AI-Powered Furniture Quality Inspection?

AI-powered furniture quality inspection uses artificial intelligence to check for defects. It analyzes the materials, shapes, and craftsmanship of wooden furniture.

The system can spot issues that the human eye might miss. This includes tiny cracks, uneven finishes, or structural weaknesses.

This improves the overall quality of the furniture, making sure customers receive the best products. With AI, you can inspect furniture more consistently. It doesn’t get tired, and it doesn’t overlook small details. This ensures that each item passes strict quality standards.

Why Furniture Quality Inspection Matters

Quality inspection is essential for maintaining high standards. Furniture needs to be durable. It should also look appealing. A single defect can ruin a customer’s experience. If quality is not maintained, it can hurt a company’s reputation.

AI helps avoid these issues. By improving the furniture quality inspection process, businesses can catch mistakes early. This reduces the cost of returns and improves customer satisfaction. A good inspection system is vital for success in the competitive furniture market.

How AI is Transforming Furniture Quality Inspection

In traditional furniture quality inspection, manual labor is the main method used to check for imperfections. Workers typically look for flaws in the wood, joints, and finishes. However, human inspection is not perfect. Fatigue, repetition, and human error can cause inconsistencies and missed defects.

Repetitive tasks. AI systems, on the other hand, handle repetitive tasks with ease. They use advanced cameras, sensors, and algorithms to inspect every centimeter of the furniture with precision. If a defect is found, the system flags it immediately for review. This means that errors are detected faster and more consistently than in manual processes.

Increased speed. One of the biggest advantages of AI-powered furniture quality inspection is speed. AI can analyze large volumes of data quickly, allowing inspections to be completed in seconds rather than minutes or hours. This faster process improves production rates without sacrificing quality.

Greater accuracy. AI also enhances accuracy. It can detect tiny flaws, such as small cracks or uneven surfaces, that might be missed by human inspectors. The system ensures that every piece is inspected uniformly, leaving little room for error.

Process optimization. Manufacturers can use this data to identify patterns. It helps them make their processes smoother and improve quality.

Cost savings. In the long run, these capabilities lead to significant cost savings. Fewer defects also mean an improvement to customer satisfaction. Manufacturers can avoid costly repairs or replacements and maintain a strong reputation in the market.

AI and Sustainable Furniture Production

Sustainability is a big concern in today’s world. Consumers are more aware of the environmental impact of the products they buy. AI can also help in this area.

AI systems can optimize the use of materials during furniture production. This reduces waste. By ensuring that each piece of furniture is inspected properly, companies can avoid throwing away defective items.

The more efficient the furniture quality inspection process, the fewer materials are wasted. This contributes to more sustainable production.

In addition, AI systems use energy more efficiently. They require less manual labor, which can help reduce the overall carbon footprint of the manufacturing process. For companies looking to adopt greener practices, AI offers a solution that aligns with their goals.

EasyODM’s AI Solutions for Wood Flooring Quality Control

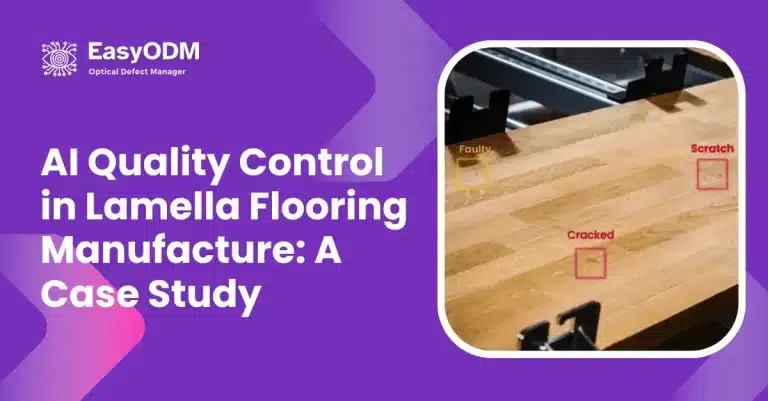

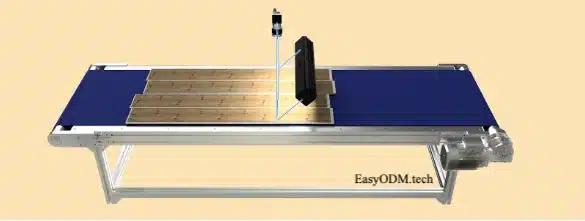

Beyond wooden furniture, AI plays a crucial role in maintaining quality standards for wood flooring, as demonstrated by EasyODM’s innovative solutions. Our solutions show how useful AI can be.

EasyODM specializes in AI-based tools for wood flooring quality control. It offers a system tailored to detect both common and uncommon defects. These include cracks, surface inconsistencies, and color variations that can impact the appearance and durability of flooring products.

Our advanced machine learning algorithms inspect each plank in real-time. This ensures only high-quality flooring reaches the market. By reducing inspection times and improving accuracy, this solution helps manufacturers cut costs and maintain consistent product standards.

The Future of AI in Wooden Furniture Quality Inspection

The future of AI in wooden furniture quality inspection is driven by advancements in machine learning, predictive analytics, and multispectral imaging. These technologies promise better accuracy and faster results. They also have the ability of predicting defects before they occur.

Predictive analytics lets AI find possible quality issues by looking at past data. Multispectral imaging uses different light wavelengths to find wood flaws, like moisture issues or hidden cracks.

Overall, AI and other emerging industry 4.0 technologies have already been able to optimize the manufacturing process by reducing equipment downtime by 30% to 50%. As these technologies grow, AI systems are likely to achieve even more success.

Conclusion

AI is revolutionizing the furniture industry. It offers a faster, more accurate, and cost-effective way to inspect wooden furniture. AI powered furniture quality inspection ensures that customers receive products of the highest quality.

As technology continues to improve, we can expect AI to play an even bigger role in wooden furniture quality inspection. For companies looking to stay competitive, adopting AI solutions is a smart move. Not only does it improve product quality, but it also contributes to more sustainable and efficient production processes.