In many industries, metal bolts play a crucial role. They are used in cars, airplanes, buildings, and machines. The quality of these bolts is very important. If a bolt has a defect, it can cause big problems. Defects can make things unsafe and lead to costly repairs. Therefore, it is essential to detect defects in metal bolts accurately and efficiently.

The Importance of Quality Metal Bolts

Metal bolts need to be strong and reliable. Defects in bolts, such as cracks, dents, or size errors, can cause failures. This is why inspecting bolts to ensure they are free from defects is vital.

Traditional Methods of Defect Detection

Traditionally, people inspect bolts manually. They also use techniques like visual inspection, ultrasonic testing, and X-ray imaging. These methods rely heavily on human inspectors, who can get tired and miss defects. These methods can also be slow and may not catch all defects.

How AI Improves Defect Detection

Artificial intelligence (AI) has made defect detection much better. Here’s how AI helps:

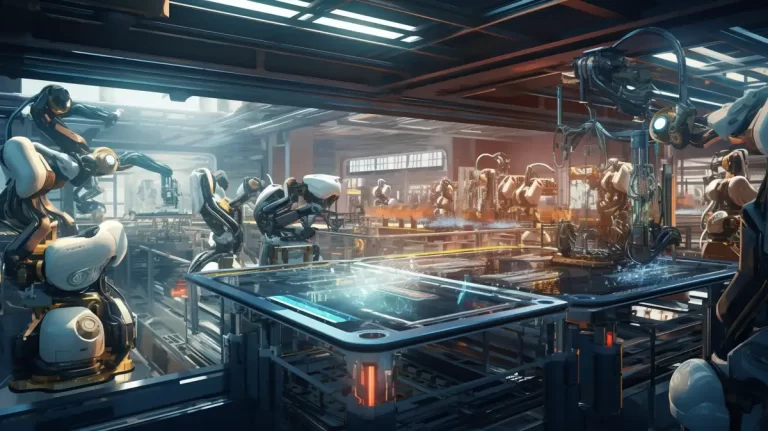

- Automated Visual Inspection: AI uses cameras and computer vision to inspect bolts automatically. High-resolution images of the bolts are taken and analyzed by AI. This method can find tiny defects that humans might miss.

- Real-Time Monitoring: AI can monitor the production process in real-time. This means defects can be found and fixed immediately, preventing defective bolts from being used.

- Predictive Analytics: AI can look at past data to predict future defects. By finding patterns, AI helps identify the causes of defects so they can be prevented.

- Enhanced Non-Destructive Testing: AI makes traditional testing methods better. For example, AI can analyze ultrasonic waves and X-ray images more accurately, highlighting potential defects.

- Continuous Learning: AI systems learn and improve over time. As they analyze more bolts, they get better at finding defects and adapting to new defect types.

Conclusion

In conclusion, AI-driven defect detection is changing the inspection of metal bolts, making the process more accurate and efficient. Companies looking for top-notch AI solutions for bolt defect detection can rely on EasODM.tech to provide advanced and effective systems.

Want Flawless Product Quality?

Book a free strategy call to see how AI-powered inspection can streamline your production.

Gediminas Mickus

Business Development Manager