Machine vision is changing the way that plastic bottle quality inspection is managed in the manufacturing process.

Machine vision systems increase the accuracy of inspections and significantly speed up the process, ensuring that products meet high quality standards before they reach consumers.

The Role of Machine Vision in Quality Assurance

Machine vision technology employs sophisticated imaging and processing to automatically detect defects in plastic bottles.

This method provides a robust solution to the limitations of manual inspections, which are often slow and prone to errors.

How the System Works

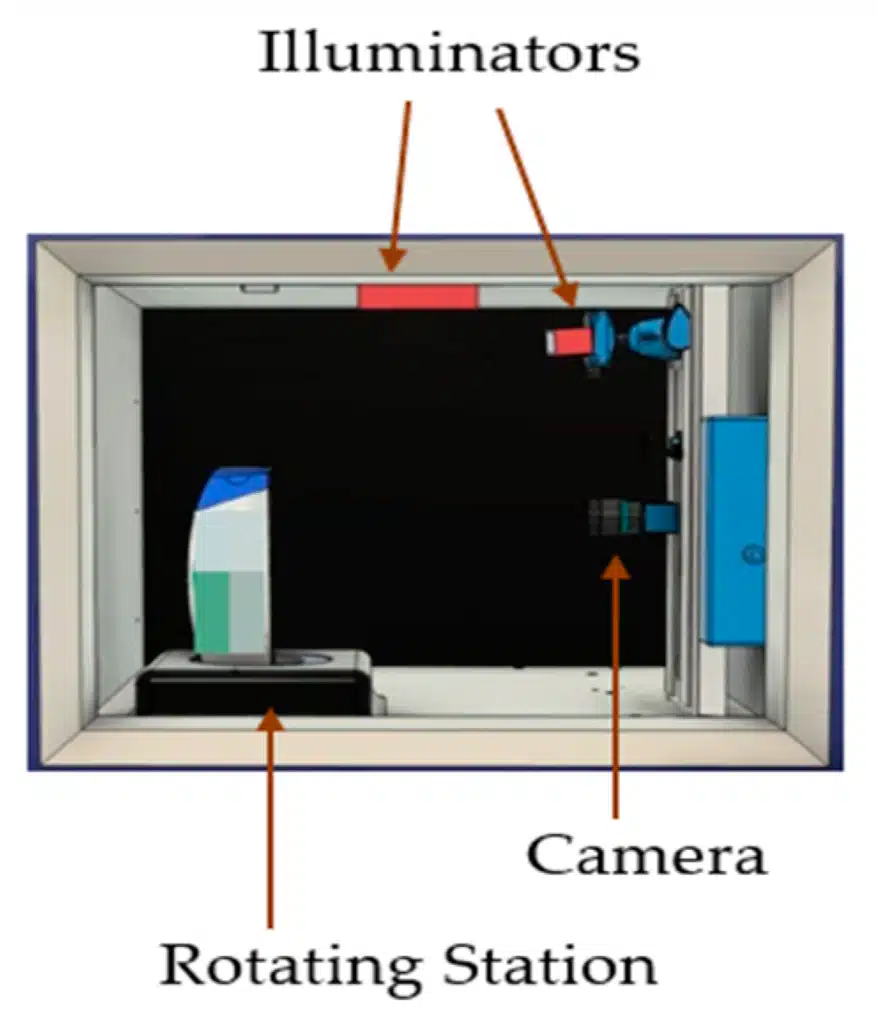

Machine vision quality inspection system consists of a high-resolution industrial cameras and led illumination, which provides the optimal conditions for capturing detailed images of each bottle.

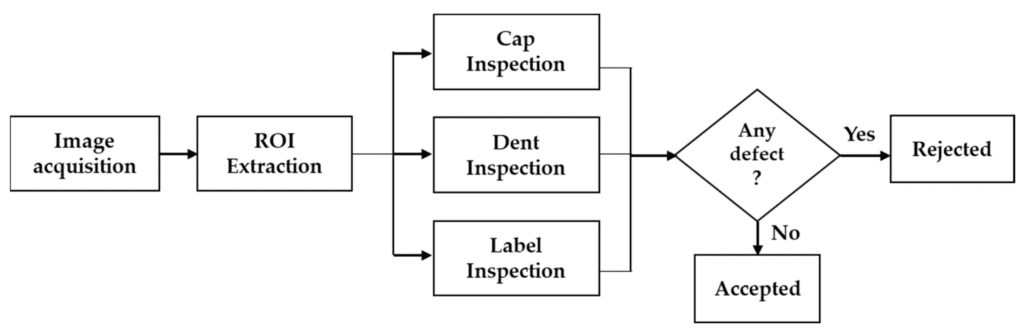

These images are then analyzed using image processing algorithms with machine vision software, like EasyODM, that identify and classify defects such as cap misfits, dents, and label misalignments.

Performance and Results

The effectiveness of the vision systems is proven through testing, demonstrating an impressive 95% accuracy rate in detecting a variety of defects across different bottle types and sizes.

| Defect Type | Number of Samples | Correct Detections | False Detections | Accuracy |

|---|---|---|---|---|

| Cap Defect | 30 | 30 | 0 | 100% |

| Dent Defect | 20 | 18 | 2 | 90% |

| Label Defect | 15 | 14 | 1 | 93% |

These results clearly prove the ability to reliably identify defects, significantly reducing the risk of defective products reaching the market.

Advantages Over Traditional Methods

The primary advantages of using machine vision for plastic bottle inspection include:

- Speed: The system can process and analyze images much faster than human inspectors, enabling high-speed production without sacrificing quality.

- Accuracy: With a high accuracy rate, the system minimizes the likelihood of defects, ensuring that products consistently meet quality standards.

- Cost-Efficiency: By automating the inspection process, labor costs are reduced and waste is minimized by catching defects early in the production process.

Real-World Application

In practice, machine vision systems have been seamlessly integrated into production lines, where they continuously inspect bottles at various stages of manufacturing.

This integration ensures that any defects are detected as early as possible, preventing further processing of defective items and saving both time and resources.

Conclusion

Machine vision represent a transformative approach to quality inspection in plastic bottle manufacturing and plastic industry itself.

By integrating these systems into production processes, a level of reliability and efficiency is achieved that is simply not possible with manual inspection.

As the technology continues to advance, the adoption and refinement of these systems ensures that they remain at the forefront of quality assurance practices.