In today’s busy world of manufacturing and retail, having accurate product labels is very important. Product labels are the first thing customers see and provide essential information like ingredients, instructions, warnings, and branding. Incorrect or faulty labels can cause big problems, from unhappy customers to legal issues. AI inspection is a new solution that is changing how companies ensure their product labels are correct.

The Importance of Accurate Product Labels

Product labels have several important roles:

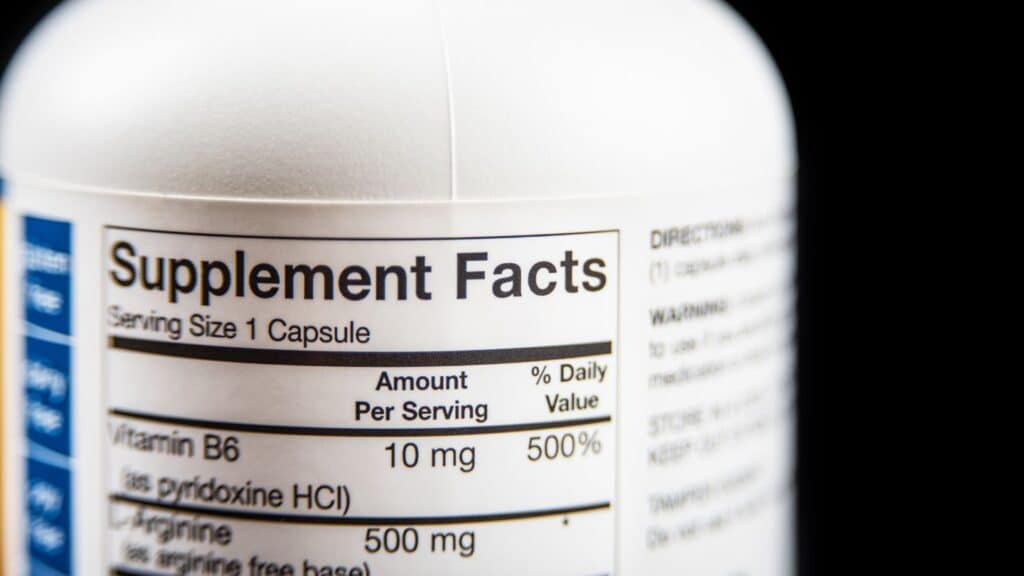

- Following Rules: Many industries have strict rules about labeling. For example, the food industry must follow guidelines to ensure all nutritional information and allergen warnings are correct.

- Brand Consistency: Labels are a key part of a brand’s identity. Inconsistent or incorrect labels can hurt the brand’s image and trust with customers.

- Consumer Safety: Accurate labels are crucial for consumer safety, especially for products with allergens or dangerous materials.

Problems with Traditional Label Inspection

Traditionally, inspecting product labels is done manually by people. This method has several challenges:

- Human Error: Even the best inspectors can miss errors, especially when there are many products.

- Inconsistency: Different inspectors might have different standards, leading to inconsistent checks.

- Time-Consuming: Manual inspection is slow and can delay production.

How AI-Powered Label Inspection Works

Artificial Intelligence (AI) provides a powerful alternative to traditional label inspection. By using technologies like machine learning and computer vision, AI systems can inspect labels quickly and accurately. Here’s how it works:

- Image Capture: High-resolution cameras take pictures of product labels as they move on the production line.

- Image Processing: The images are processed using computer vision to identify the label on the product.

- Analysis: AI models, trained on many label images, check the labels for things like text accuracy, font size, color consistency, barcode readability, and required information.

- Anomaly Detection: Any errors detected by the AI system are flagged for review or automatic rejection.

Benefits of AI Inspection

- Better Accuracy: AI systems can find even small errors that human inspectors might miss, ensuring higher accuracy.

- Consistency: AI provides consistent inspection standards, removing the variability of human inspectors.

- Speed: AI inspection is much faster than manual methods, allowing for real-time quality control and reducing delays.

- Cost Efficiency: By reducing the need for manual labor and minimizing costly errors, AI inspection can save money.

- Data Insights: AI systems can collect and analyze data from inspections, providing valuable information about common labeling issues and helping improve the production process.

Real-World Applications

Several industries are already benefiting from AI-powered label inspection:

- Food and Beverage: Ensuring labels accurately list ingredients, nutritional information, and expiration dates.

- Pharmaceuticals: Verifying that drug labels meet regulatory standards and include important information like dosage instructions and warnings.

- Consumer Goods: Maintaining brand consistency and ensuring product information is clear and accurate.

Future Trends

The future of AI inspection for product labels looks promising, with ongoing advancements in AI technology bringing even more improvements. We can expect more advanced algorithms capable of handling complex label designs and a wider range of products. Additionally, integration with other AI-driven quality control systems will further streamline manufacturing processes and enhance overall product quality.

Conclusion

AI inspection for product labels represents a big step forward in quality control, offering unmatched accuracy, consistency, and efficiency. As more industries adopt this technology, we can expect a future where product labeling errors are almost eliminated, enhancing consumer safety, regulatory compliance, and brand integrity. Embracing AI inspection is not just a technological upgrade; it’s a strategic move towards a smarter, more reliable manufacturing process.

EasyODM.tech can provide this advanced solution to ensure your product labels are accurate and compliant. If you need this solution, contact us for more information.