The food and beverage industry is crucial to daily life. Ensuring food safety and quality is vital for public health and consumer satisfaction. In the past, quality control relied on manual processes. These methods were slow and prone to human error.

With the rise of artificial intelligence (AI), quality control is now faster, more accurate, and cost-effective. AI in food and beverage quality control is transforming the industry. It is reshaping how food is inspected and managed throughout production.

Key takeaways:

- Food Sorting and Classification:

AI automates sorting based on size, shape, and quality. This improves efficiency and ensures consistency in product quality. - Automated Quality Inspection of Food Products:

AI inspects meat, seafood, dairy, and grains for defects and contamination. These automated inspections ensure higher safety and quality standards. - AI and Predictive Maintenance in Food Production:

AI predicts when equipment needs repairs to prevent breakdowns. This minimizes disruptions and helps maintain food quality.

Why AI is Important for Food Quality Control

Consumers today want food that is fresh, safe, and high-quality. To meet these demands, companies need better quality control measures. Manual inspections are no longer enough.

AI in food and beverage quality control ensures that products meet safety standards more reliably. AI systems process large amounts of data quickly and detect problems before they become major issues.

AI-driven systems help automate food safety protocols. They keep food safe throughout the entire supply chain, from production to delivery. These systems rely on sensors and cameras to detect defects, contamination, or other issues. They work faster and more accurately than humans.

1.Food Sorting and Classification

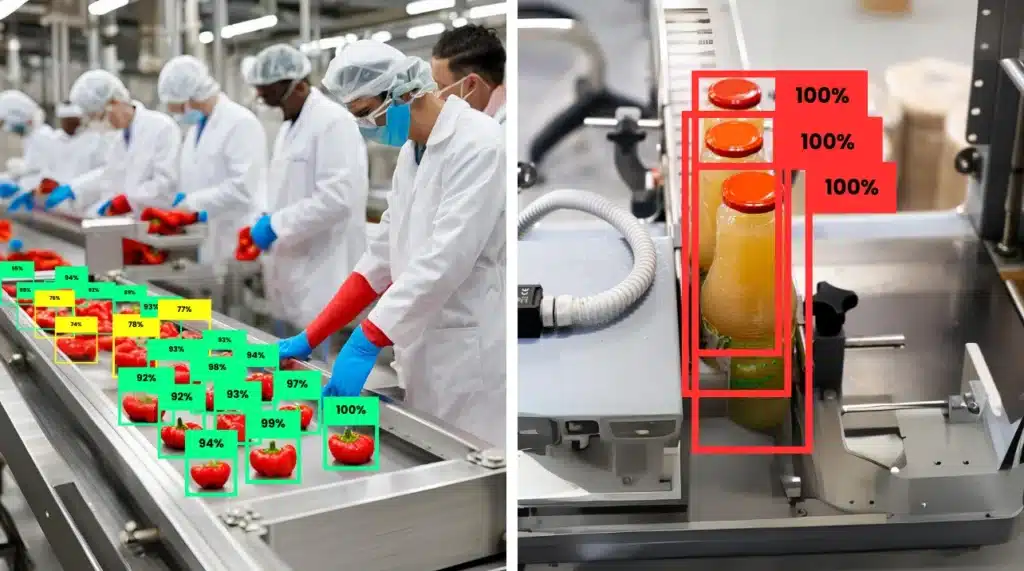

AI-powered computer vision is changing how food products are sorted and classified. Sorting food by size, shape, and quality is tedious for humans, but AI automates this task.

This improves efficiency. AI-driven systems assess food items based on specific parameters. They ensure that only high-quality products move forward in the production line.

Ripeness and Freshness Evaluation

Consumers expect fruits and vegetables to be fresh. AI helps companies meet this expectation by checking ripeness and freshness.

AI systems analyze color, texture, and shape to decide if the food is ready for sale. This cuts food waste by letting companies remove overripe products before they spoil.

A clear example is tomato sorting. AI algorithms scan tomatoes for size, color, and softness. If the system finds a problem, like a damaged or overripe tomato, it removes the product.

This process improves the speed and accuracy of food production while ensuring that product quality stays consistent. AI in fruit and vegetable grading also helps spot imperfections that the human eye might miss, making the sorting process more precise.

AI-Based Tomato Sorting Algorithm

AI’s role in tomato sorting is a great example of its precision. According to a study, here’s how the AI-based tomato sorting algorithm works:

- The system takes a picture of the tomato and checks its softness.

- The AI uses image processing to predict the type and quality of the tomato.

- The system confirms the prediction by checking the softness value.

- If the tomato is damaged, the system discards it.

- If the tomato is not ripe, it is left aside.

- When the tomato is ready, it is picked and stored for packaging or sale.

This process ensures that only high-quality tomatoes make it to the shelves. It also cuts waste and speeds up production, showing how effective AI can be in food sorting.

2.Automated Quality Inspection of Food Products

AI is transforming the inspection process for various food products, including meat, dairy, seafood, and grains. AI in food and beverage quality control systems inspect for defects, contamination, and foreign materials automatically. This ensures that only safe, high-quality products make it to consumers.

Meat Inspection

AI systems can scan meat products for defects or contaminants. These systems work fast to check for foreign materials or quality issues that could harm food safety. This ensures meat products meet high standards before reaching consumers.

Seafood Inspection

In seafood inspection, AI detects parasites, contaminants, and other quality issues. AI systems also monitor for discoloration or texture changes. These inspections ensure that seafood is fresh, safe, and meets regulatory standards.

Dairy Product Inspection

AI is also improving how dairy products are monitored. Dairy products like milk, yogurt, and cheese must meet strict standards for consistency and flavor. AI systems monitor production to ensure these products meet safety and quality rules.

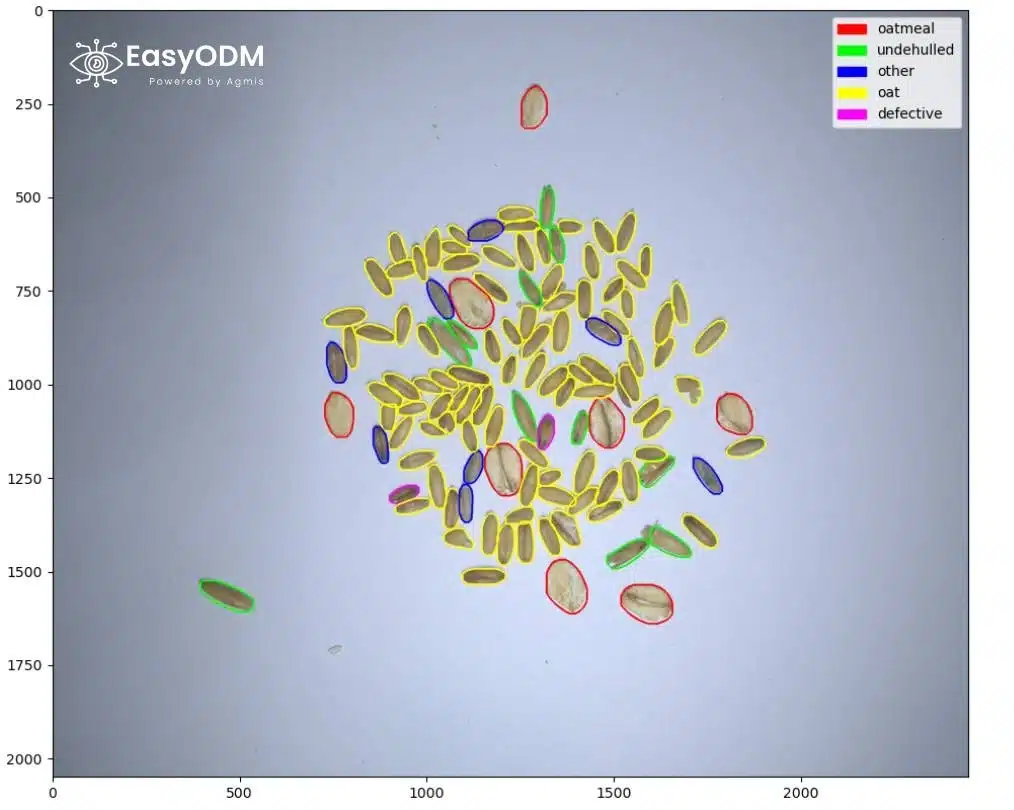

Grain Quality Inspection

EasyODM’s AI-driven grain sample analysis has changed the inspection process by reducing the time it takes to inspect grain samples. AI systems inspect grains 30 times faster than manual methods, with 96% accuracy. This automation ensures that grains meet quality standards and reduces human error.

3.AI and Predictive Maintenance in Food Production

AI plays an important role in keeping food production equipment reliable and functional, which directly affects quality control.

Predictive maintenance uses AI to monitor machinery. AI systems predict when machines need repairs, helping prevent breakdowns that could disrupt production or cause contamination.

By preventing equipment failures, AI ensures that food production continues smoothly, reducing the chances of contamination or quality issues caused by malfunctioning equipment.

Challenges and Solutions in AI for Food Quality Control

While AI offers many benefits, using it in food quality control can be challenging. The initial cost of setting up AI systems can be high. Companies need advanced equipment, sensors, and AI algorithms. Employees also need training to use these new systems.

However, the long-term benefits of AI outweigh the initial costs. As technology improves, AI is becoming more affordable for food manufacturers. AI-powered systems can be customized to meet the needs of each company, making them more versatile.

Future of AI in Food and Beverage Quality Control

The future of AI in food and beverage quality control looks promising. AI systems are becoming more accurate and efficient. This is because machine learning and computer vision technologies are continuing to evolve.

In the future, AI will likely take on more complex tasks. These may include predicting supply chain disruptions and optimizing production based on demand..

AI-powered robots will continue to be key in food production. Automated sorting systems will become more precise, handling delicate food items with ease.

AI’s ability to predict product shelf life and manage inventory will help manufacturers meet the rising demand for fresh, safe, and high-quality food.

Conclusion

AI is transforming the food and beverage industry by improving quality control. From sorting and classifying food to ensuring freshness and preventing spoilage, AI is a powerful tool for keeping food safe.

AI in food and beverage quality control increases efficiency, lowers costs, and supports sustainability efforts. As the demand for high-quality, safe food grows, AI will take on an even bigger role in the future of food production.