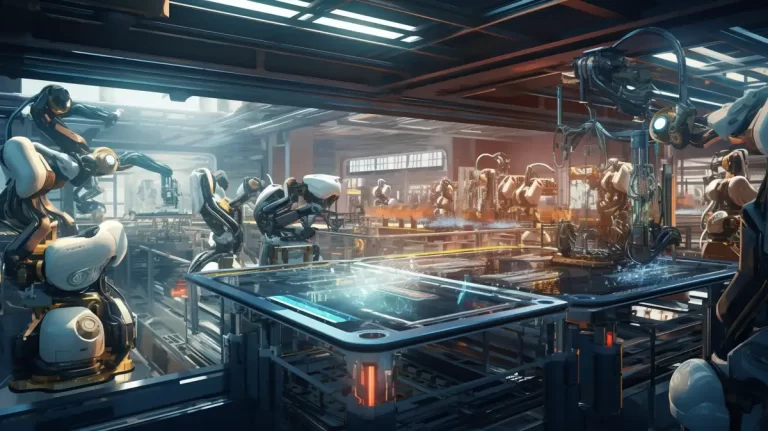

The manufacturing industry has changed a lot in recent years because of new technology. One of the biggest changes is using artificial intelligence (AI) to check the quality of products. AI inspection of stamped metal parts is a key innovation, making the process faster and more accurate. This article explains how AI inspection works and its benefits.

Why Quality Control is Important in Metal Stamping

Metal stamping is used to make many products, like car parts and household items. It’s important to check the quality of these metal parts to prevent problems like product failures and safety issues. Traditional methods of checking parts can be slow and prone to mistakes.

How AI Inspection Works

AI inspection uses advanced technology to look at and evaluate stamped metal parts. Here are the steps involved:

- Data Collection: High-resolution cameras and sensors take detailed pictures or scans of the metal parts.

- Data Processing: The images are cleaned up to make sure the AI can understand them correctly.

- Feature Extraction: The AI identifies important features in the images, such as edges and textures.

- Defect Detection: The AI compares these features to known standards to find any defects.

- Reporting: The AI classifies the defects by type and severity and creates a report with the findings and suggested actions.

Benefits of AI Inspection

Using AI inspection in the metal stamping industry offers many benefits:

- Higher Accuracy: AI systems can find defects more accurately and consistently than human inspectors.

- Faster Processes: Automated inspection is much faster than manual methods, speeding up production.

- Cost Savings: By reducing defects and rework, AI inspection can save a lot of money over time.

- Scalability: AI inspection systems can handle different production volumes, making them suitable for both small and large operations.

- Data Insights: The data collected can help identify patterns and improve manufacturing processes.

Real-World Applications

AI inspection is already being used in several industries:

- Automotive Industry: Car manufacturers use AI to ensure the quality of important parts like engine and body components.

- Aerospace Sector: AI helps maintain the high standards needed for aerospace components.

- Electronics Manufacturing: AI ensures the precision and durability of metal housings for electronic devices.

Conclusion

AI inspection of stamped metal parts is a major advancement in quality control. By using AI, manufacturers can achieve higher accuracy, speed, and cost savings. As the technology continues to improve, it will set new standards for quality in the manufacturing industry.

We at EasyODM.tech are leading this transition, providing innovative AI inspection solutions to help manufacturers maintain top-notch quality and stay competitive in the market.