In our quest for more efficient and accurate wood defect detection, we have turned to the promising field of artificial intelligence (AI). With the increasing demand for wood products and the need to minimize production costs, the accurate identification of wood defects has become crucial. Wood defects such as growth irregularities, pest damage, and processing flaws can significantly affect the quality and value of wood, leading to substantial financial losses.

Recognizing the importance of wood utilization and the impact of defects, researchers and industry professionals have been exploring AI-based technologies to enhance the accuracy and efficiency of wood defect detection.

One of the key areas of focus in this field is machine vision techniques. By using advanced imaging technologies and algorithms, these techniques enable the automated detection and analysis of wood defects. However, traditional machine vision methods often struggle with the complexity and variability of wood defects.

This has led to the development of deep learning-based approaches, which utilize neural networks to learn and recognize patterns in large-scale image datasets. With the ability to capture intricate details and variations in wood defects, deep learning techniques have shown great potential in improving the accuracy of wood defect detection.

By harnessing the power of AI, we can revolutionize wood processing industries by reducing costly errors and ensuring the highest quality of wood products.

Key Takeaways

– Wood utilisation is an important factor in production costs, but the combined utilisation rate of wood is generally only 50 to 70%.

– Wood defects can lead to wasted resources, safety hazards, and instability in buildings.

– Manual observation methods for identifying timber defects are subjective and have an accuracy of only around 70%.

– Various wood defect recognition technologies can improve the accuracy, efficiency, and cost-effectiveness of detecting and identifying wood defects.

Wood Defect Detection Methods

Now let’s dive into the different methods used for detecting wood defects and how they contribute to improving wood quality.

Wood defect detection methods have evolved over time, with advancements in technology and the rise of artificial intelligence (AI). One commonly used method is machine vision, which involves capturing images of the wood surface and using image processing techniques to identify and classify defects.

This method relies on the extraction of features such as color, texture, and shape to differentiate between normal wood and defects. Machine vision software have been effective in detecting surface defects such as knots, cracks, and discoloration. However, they may have limitations in detecting internal defects or defects that are not visually apparent.

Another approach that has gained traction in recent years is the use of artificial neural networks (ANNs) for wood defect detection. ANNs are computational models inspired by the structure and function of the human brain. They can learn from a large amount of training data and make predictions or classifications based on that learning.

In the context of wood defect detection, ANNs have been trained on a dataset of images of both normal wood and various types of defects. The network learns to identify patterns and features that distinguish between the two, and can then accurately classify new wood samples as either normal or defective. This method has shown promising results in improving the accuracy of wood defect detection.

Deep learning, a subset of machine learning, has also been applied to wood defect detection. Deep learning algorithms, such as convolutional neural networks (CNNs), have the ability to automatically learn hierarchical representations of data. These networks consist of multiple layers of interconnected nodes, each performing a specific operation on the input data. CNNs have been successful in various image recognition tasks, including wood defect detection. They can effectively capture complex features and patterns in wood images, leading to more accurate and robust defect detection.

The use of AI techniques such as machine vision, artificial neural networks, and deep learning has significantly improved the accuracy of wood defect detection. These methods allow for the automated and efficient identification of defects, leading to improved wood quality and reduced waste. As technology continues to advance, we can expect further developments in wood defect detection methods, ultimately benefiting the wood industry and the conservation of forest resources.

Machine Vision Techniques

Using machine vision techniques, researchers have developed innovative methods to enhance the identification and recognition of wood defects, leading to more accurate and efficient detection in wood processing. These methods utilize advanced image analysis algorithms and neural networks to analyze images of wood surfaces and identify various types of defects.

By training the neural network with a large dataset of annotated images, the system can learn to recognize different patterns and textures associated with wood defects. This enables the system to accurately classify and locate defects such as knots, cracks, decay, and discoloration.

The application of machine vision wood defect detection based on neural networks has several advantages. First, it significantly improves the defect recognition accuracy compared to traditional manual observation methods. The neural network can analyze images with high precision and consistency, reducing the chances of missed or misidentified defects.

Second, machine vision techniques allow for real-time and automated defect detection, eliminating the need for manual inspection and reducing the time and cost associated with the process. This enables wood processing companies to achieve higher production efficiency and reduce waste.

Lastly, the use of machine vision techniques in wood defect detection opens up possibilities for further advancements in the field. Researchers can continue to refine and optimize the algorithms and neural networks to improve the accuracy and speed of defect recognition, leading to even greater efficiency and cost savings in wood processing operations.

Deep Learning for Wood Defects

By harnessing the power of deep learning, researchers have revolutionized the field of wood defect recognition, paving the way for more precise and efficient identification of flaws in wood surfaces.

Deep learning algorithms, particularly convolutional neural networks (CNNs), have shown great potential in accurately detecting and classifying wood defects. These algorithms are designed to automatically learn and extract features from images, allowing them to effectively analyze and interpret complex patterns and textures on wood surfaces.

Through extensive training on large datasets of annotated wood defect images, CNNs can learn to differentiate between various types of defects, such as knots, cracks, decay, and discoloration. This enables them to accurately identify and classify defects in real-time, with high accuracy and reliability.

One of the key advantages of deep learning for wood defect detection is its ability to perform automated defect classification. Traditional image processing techniques often require manual feature extraction and selection, which can be time-consuming and subjective. In contrast, deep learning models can automatically learn and extract relevant features from raw image data, eliminating the need for manual intervention.

This not only improves the efficiency of defect detection but also reduces the reliance on human expertise. Additionally, deep learning models can be trained to detect subtle and complex defects that may be difficult for human inspectors to identify. This enhances the overall accuracy and reliability of wood defect detection systems, ensuring that defects are not missed during the inspection process.

Overall, the integration of deep learning algorithms into wood defect recognition systems holds great promise for improving the accuracy and efficiency of defect detection in the wood processing industry.

Real-Time Detection Systems

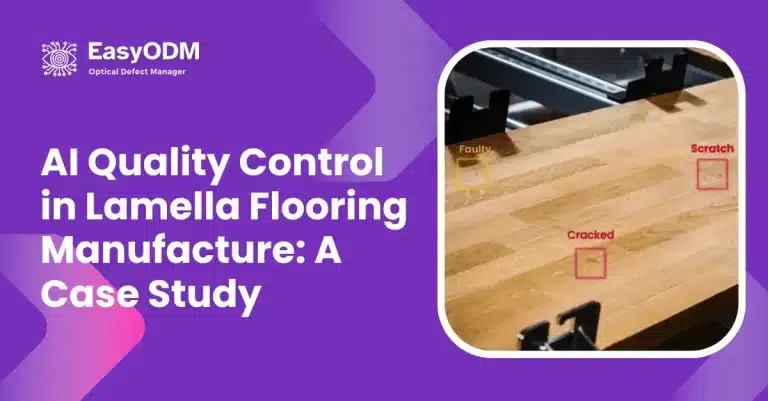

With the advancements in deep learning, real-time wood defect detection systems can now quickly and accurately identify and classify defects on wood surfaces, enabling immediate action to be taken to prevent further damage or waste.

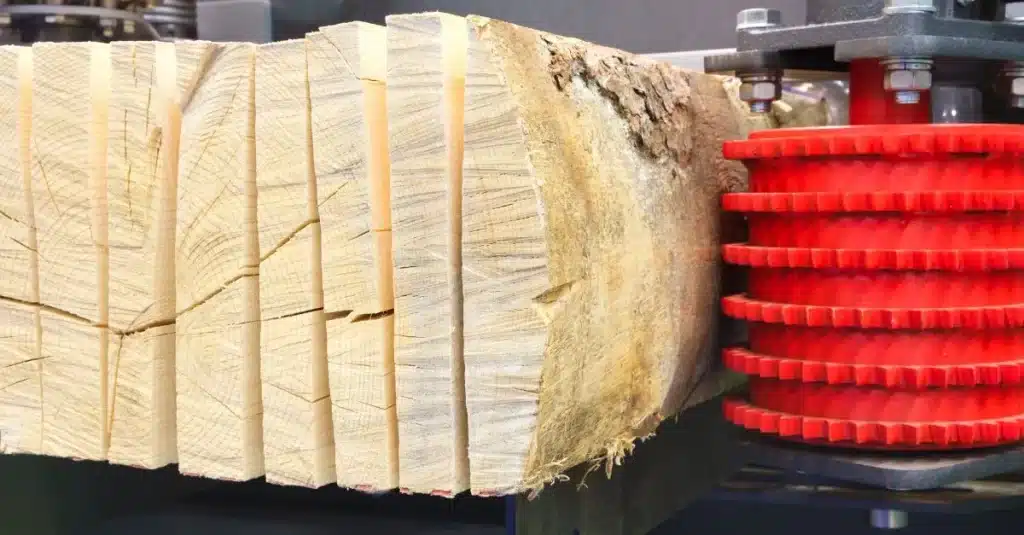

For example, a sawmill can implement a real-time detection system that uses cameras and deep learning algorithms to continuously monitor the wood as it moves along the production line, automatically detecting and categorizing defects such as knots, cracks, and decay.

If a defect is identified, the system can send an alert to the operator, allowing them to quickly remove the defective piece and prevent it from affecting the quality of the final product.

Real-time detection systems can significantly improve the efficiency of wood defect detection and classification. By using deep learning algorithms, these systems can analyze images of wood surfaces in real-time, accurately identifying and categorizing defects such as knots, cracks, and decay. This allows for immediate action to be taken, preventing further damage or waste.

Implementing real-time detection systems can help reduce manual inspection and improve the overall productivity of wood processing lines. With automated defect detection, operators can focus on other tasks while the system continuously monitors the wood for defects. This not only saves time and labor costs but also ensures that defects are quickly identified and removed from the production line.

Real-time detection systems can also contribute to cost savings and resource conservation. By preventing defective pieces from entering the production process, these systems reduce the amount of waste generated and improve the overall yield of usable wood. This is particularly important in the context of sustainable wood production and conservation of forest resources.

Machine learning and deep learning algorithms play a crucial role in the accuracy and effectiveness of real-time wood defect detection systems. These algorithms are trained on large datasets of labeled wood surface images, allowing them to learn and recognize different types of defects with high accuracy.

The use of real-time detection systems can enhance quality control in wood processing. By continuously monitoring the wood for defects, these systems ensure that only high-quality pieces are used in the production of finished wood products, improving customer satisfaction and reducing the risk of safety hazards.

Neural Network-Based Detection

Imagine how neural network-based detection can revolutionize the way you identify and classify wood defects, providing a faster and more accurate solution for ensuring the quality of your wood products.

Neural network-based detection refers to the use of deep convolutional neural networks (CNNs) to analyze and interpret images of wood surfaces, effectively identifying and categorizing defects. This approach utilizes the power of artificial intelligence (AI) to learn from large datasets of labeled images, enabling the neural network to recognize patterns and features associated with different types of wood defects.

By training the neural network on a diverse range of wood defect images, it becomes capable of accurately detecting and classifying defects with a high level of precision.

The use of neural network-based detection offers several advantages over traditional manual observation methods or other automated defect detection techniques. Firstly, it significantly improves the accuracy of defect detection, as the neural network is able to identify subtle and complex patterns that may not be easily discernible to the human eye. This ensures that even the smallest defects are detected, reducing the risk of missed or misclassified defects.

Secondly, neural network-based detection is highly efficient, capable of processing large volumes of wood surface images in a short amount of time. This allows for real-time defect detection, enabling immediate action to be taken to remove or repair defective wood, thereby enhancing production efficiency.

Lastly, the use of AI in wood defect detection based on neural networks is a cost-effective solution. Once the neural network is trained, it can be easily deployed and utilized across different wood processing lines, eliminating the need for extensive manual inspections and reducing labor costs.

Overall, neural network-based detection holds great potential in improving the accuracy and efficiency of wood defect detection, ultimately leading to higher quality wood products and reduced waste.

Large-Scale Image Dataset

Picture a vast ocean filled with thousands of colorful fish, each one unique and distinct. In order to accurately identify and classify these fish, a comprehensive and diverse dataset of their images is essential.

The same concept applies to wood defect detection accuracy in the wood industry. To improve the accuracy of wood defect detection using AI, a large-scale image dataset is crucial. This dataset should include a wide variety of wood defects, captured from different angles and under various lighting conditions.

By training AI models on this dataset, they can learn to recognize and classify different types of wood defects with higher accuracy. A large-scale image dataset allows AI algorithms to learn the intricate details and patterns of wood defects, enabling them to make more precise identifications.

The dataset should cover a wide range of wood defects, including growth defects, pest damage, and processing defects. By incorporating machine learning techniques, the AI models can continuously improve their accuracy over time, as they learn from more examples in the dataset.

This not only enhances the efficiency of wood defect identification but also reduces the reliance on manual observation methods, which are subjective and less accurate.

Ultimately, the use of a large-scale image dataset combined with AI technology can revolutionize the wood industry by significantly improving wood defect detection accuracy and reducing waste.

Improving Detection Accuracy

In our previous discussion on the role of AI in improving wood defect detection accuracy, we examined the importance of having a large-scale image dataset for training machine learning models. By utilizing a diverse and extensive dataset, machine models can learn to accurately identify and classify various wood surface defects.

However, having a large dataset alone is not sufficient to ensure high detection accuracy. There are additional factors that need to be considered and addressed in order to improve the overall performance of the detection algorithm.

One key aspect to consider is the complexity and variability of wood defects. Wood quality can be affected by a wide range of defects, including knots, cracks, decay, and discoloration, each exhibiting unique characteristics and patterns.

In order to accurately detect and classify these defects, the algorithm needs to be able to differentiate between different types of defects and accurately identify their specific attributes. This requires the algorithm to have a deep understanding of the underlying characteristics and variations of wood defects.

By further refining the algorithm and incorporating advanced machine learning techniques, such as deep learning, we can enhance the accuracy and precision of defect detection. Deep learning models have the ability to learn complex patterns and features from the data, enabling them to make more accurate predictions and classifications.

Furthermore, by continuously training and fine-tuning the algorithm with new data, we can ensure that the model stays up-to-date with the latest variations and types of wood defects, further improving its overall detection accuracy.

While a large-scale image dataset is essential for training machine learning models in wood defect detection, it is equally important to focus on improving the detection accuracy by refining the algorithm and incorporating advanced techniques such as deep learning. By continuously enhancing the algorithm’s ability to differentiate and identify different types of defects, we can ensure higher accuracy and efficiency in wood defect recognition, ultimately leading to improved wood quality and reduced waste in the wood processing industry.

Conclusion

In conclusion, the role of AI in improving wood defect detection accuracy is crucial in the wood processing industry. Wood defects can significantly impact production costs and overall wood utilization.

By implementing machine vision techniques and deep learning algorithms, accurate and efficient wood defect detection can be achieved. Real-time detection systems, neural network-based detection, and large-scale image datasets play a vital role in enhancing detection accuracy.

Furthermore, the development and utilization of AI technology in wood defect recognition have immense potential. The use of AI not only improves the accuracy of defect detection but also reduces human error and speeds up the identification process. This technology allows for faster and more effective decision-making, leading to increased productivity and reduced costs in wood processing.

As the field continues to advance, the integration of AI into wood defect detection systems will revolutionize the industry, making it more efficient, sustainable, and economically viable.