Hardwood flooring is known for its elegance, durability, and natural appeal. But keeping the quality consistent during manufacturing can be tough. Defects like cracks, chips, and stains don’t just ruin the look—they can also weaken the structure.

Traditional inspection methods rely heavily on human judgment. This often leads to errors. It also results in inefficiencies. That’s where AI comes in. AI in hardwood flooring inspection is revolutionizing quality control processes.

Key Takeaways

- Species-Specific AI Models: AI in hardwood flooring inspection can adapt to different hardwood species. This ensures more precise defect detection for unique wood types.

- Handling Variability in Color Finishes: AI handles color and finish variations with greater efficiency. This maintains a uniform aesthetic quality.

- Lighting Adaptability: AI can adapt to changes in lighting in production. This ensures defect detection stays reliable in all conditions.

- Enhanced Data Collection: AI systems collect data that helps improve future processes. This leads to ongoing improvements in inspection methods.

- Moisture Level Control: AI can manage moisture levels during processing. This helps prevent warping or cupping in hardwood planks.

Challenges in Hardwood Flooring Quality Control

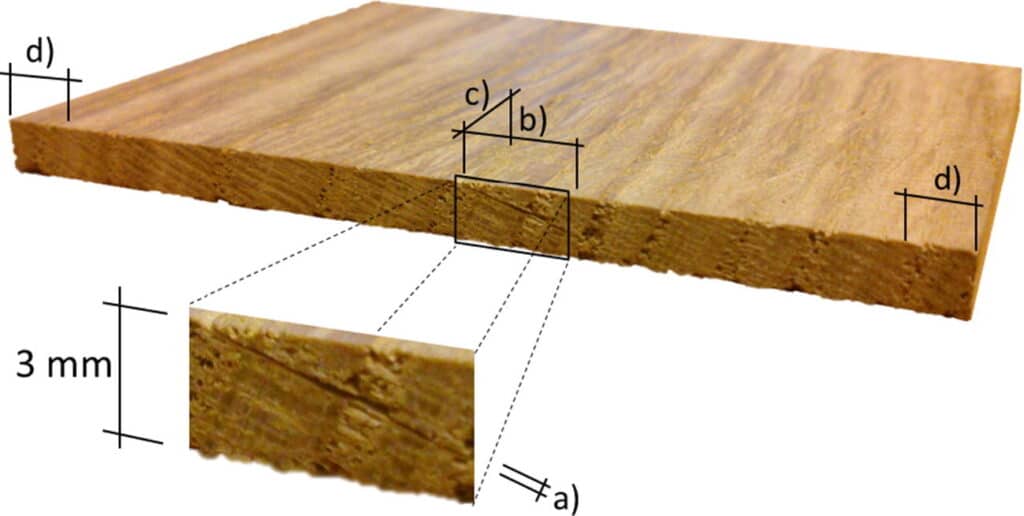

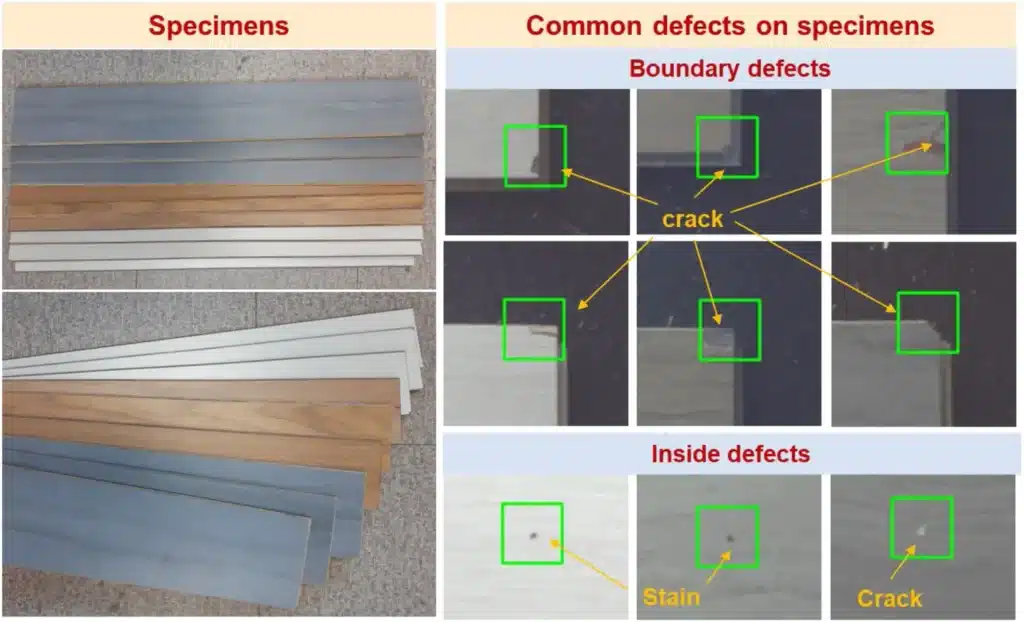

Hardwood flooring has its own set of challenges that need careful inspection. One study specifically analyzes these challenges.

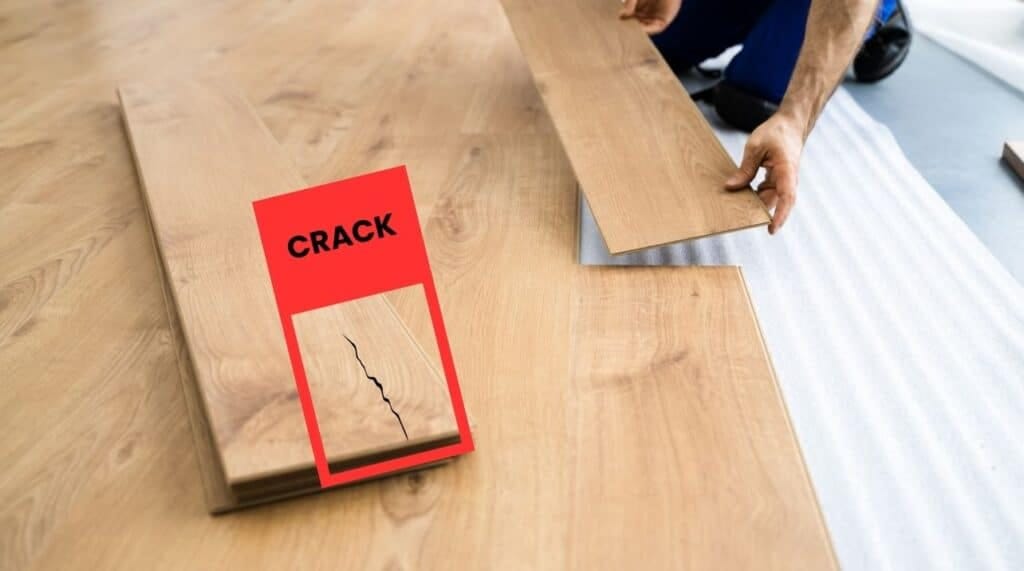

Surface cracks usually happen because of machining stresses. Subsurface cracks, on the other hand, often come from uneven drying. These subsurface cracks can reduce the wood’s strength.

AI in hardwood flooring inspection plays a vital role in detecting these subsurface cracks before they cause structural problems. This makes early detection crucial. Handling mistakes or chemical exposure can lead to edge chipping and staining.

These defects are subtle and easily missed during manual inspections. Even small differences in plank thickness or width can cause issues during installation. This leads to higher costs and dissatisfaction. Hardwood also has detailed textures.

AI in hardwood flooring inspection can analyze these textures meticulously, identifying inconsistencies that manual methods might miss. Variability in color and finish across different wood species makes inspection challenging when uniform quality is needed.

AI helps make these checks more consistent. During cutting and handling, edges can get chipped or splintered. If unnoticed, this can cause problems during installation.

AI with high-resolution cameras can catch these defects in real time. Moisture problems during drying or storage can lead to warping or cupping. These issues are difficult to detect until they become serious.

AI can integrate moisture data to predict and prevent these problems early in the production process. These challenges make one thing clear. We need advanced technologies like AI to maintain quality standards and reduce waste.

How AI is Changing Hardwood Floor Inspections

AI in hardwood flooring inspection systems bring numerous advantages, transforming how quality control is approached:

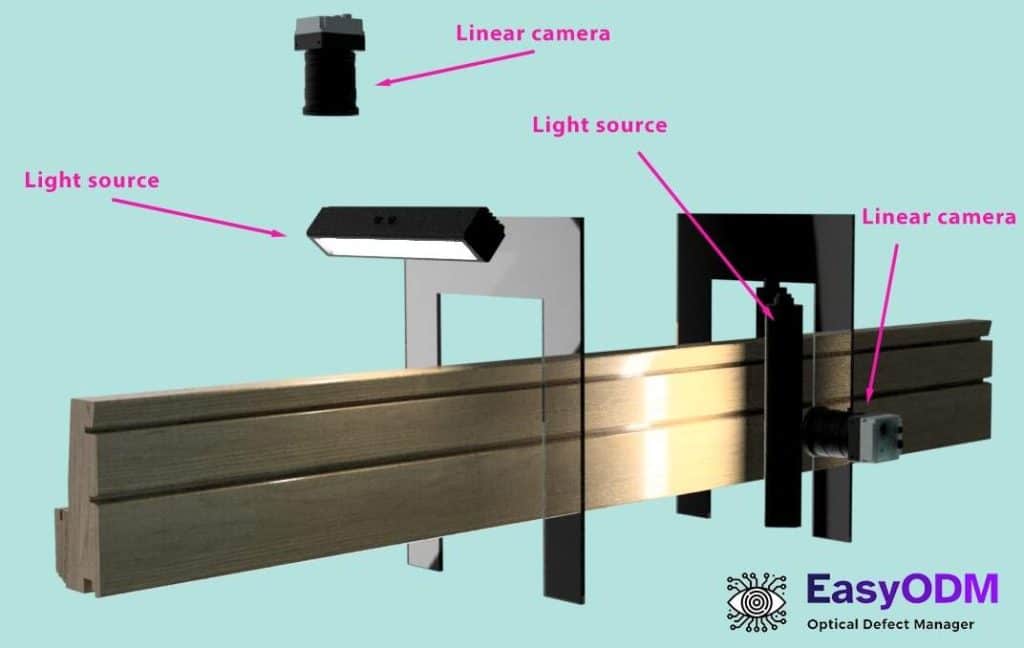

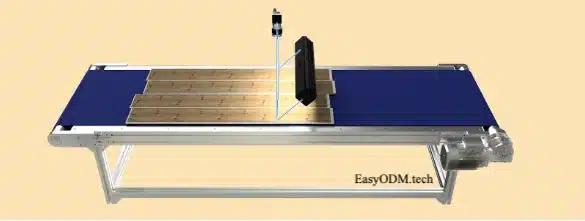

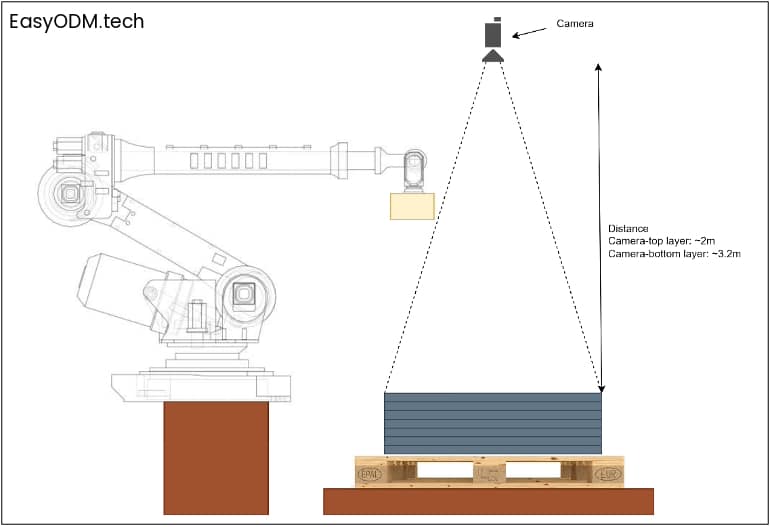

- Image Capture: High-resolution cameras take detailed pictures of each plank. These images show grain patterns, texture, and surface irregularities. Controlled lighting helps spot defects even on complex surfaces.

- Defect Detection Algorithms: CNNs help identify cracks, chips, and stains. AI in hardwood flooring inspection leverages CNNs to improve defect identification, making it more efficient and accurate. These tools take over repetitive checks, making the process faster and more reliable. In one study YOLOv5 model is being used to catch surface issues in real-time, even when patterns or lighting vary.

- Identifying Complex Patterns: AI finds complex grain patterns that human inspectors could easily miss. This ensures even subtle defects are caught.

- Reducing Waste: AI minimizes waste by identifying usable materials accurately. This saves money and benefits the environment.

- Consistent Quality: AI keeps quality consistent even at high production volumes. Studies show AI can improve defect detection by 25% compared to manual methods.

- Color and Finish Consistency: AI optimizes color and finish by detecting inconsistencies. This helps avoid costly rework and maintains quality.

- Species-Specific Customization: AI adjusts to different hardwood species, like oak and maple. This ensures inspection is tailored for each type.

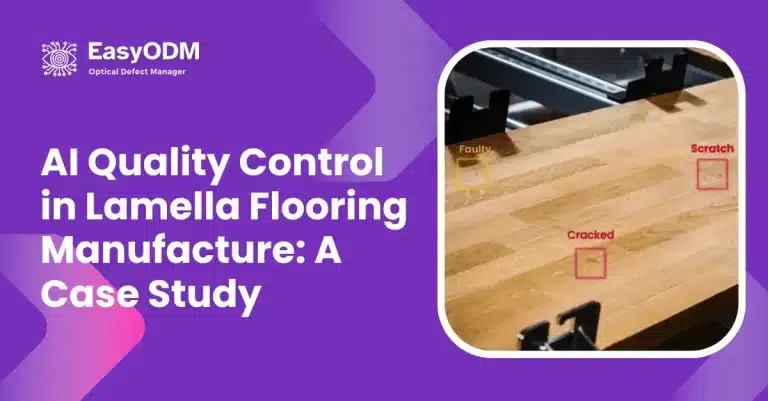

EasyODM’s AI Solutions for the Wood Industry

At EasyODM, we know wood quality control can be tough. Our AI tools help manufacturers catch issues like cracks, chips, and grain flaws. This means better quality and less waste. We offer solutions for many wood industry’s products—from flooring to plywood, lumber, and beyond.

We create tailored solutions for each client’s needs. This helps us find the right approach every time. Our tech adapts to different wood types and is easy to use, fitting right into existing processes. Focus on great products—we’ll handle the inspection.

Case Studies and Real-World

Real-world applications of AI have shown impressive improvements. AI in hardwood flooring inspection has demonstrated significant advancements in ensuring product quality.

In a study focused on hardwood flooring, CNNs proved highly effective for defect detection. They achieved an impressive 96.1% accuracy rate.

This included identifying both surface and subsurface cracks. Surface cracks, often visible, are easier to detect. Subsurface cracks, however, are hidden within the wood and require advanced techniques. CNNs excelled at spotting both types.

Their ability to analyze subtle variations in wood patterns made this possible. This level of precision significantly outperformed manual inspections. It also reduced the likelihood of defective products reaching the market.

What’s Next for AI in Hardwood Flooring Inspection?

The future of AI in hardwood flooring inspection looks bright. AI will adapt to different hardwood species, like oak, maple, and walnut.

This will lead to better defect detection. Sophisticated edge-detection algorithms will identify edge defects, like splintering and chipping. This will ensure smoother edges.

AI in hardwood flooring inspection will also enhance the finishing process. It will apply stains and varnishes consistently to deliver a flawless finish, especially for luxury products. AI models will adjust to variable lighting.

This will ensure accurate defect detection under any conditions. Real-time AI feedback will manage moisture levels. This will prevent defects like warping and cupping, maintaining high quality.

Conclusion

AI is transforming the way we handle quality inspection in hardwood flooring. Traditional methods have always struggled with the complexities of hardwood.

This often leads to inconsistencies and higher costs. AI in hardwood flooring inspection changes that by offering a level of precision that humans simply can’t match.

AI in hardwood flooring inspection makes production more efficient. It identifies subtle defects and optimizes the finishing process. As technology evolves, hardwood flooring manufacturing will become smarter. It will also be more consistent and cost-effective.