The furniture manufacturing sector often deals with the complex task of transporting small, delicate components.

A leading furniture manufacturer, specializing in such components, identified a significant bottleneck in their supply chain — the manual handling of pallet liners used to secure the components during transport.

To overcome this, EasyODM.tech was tasked to develop a computer vision system that could automate the process of detecting and managing these liners, ensuring both palletizing and depalletizing processes.

Challenge

Manual identification and handling of pallet liners between product layers are time-consuming and prone to errors.

In fast-paced production environments, these inefficiencies can lead to significant delays and increased operational costs.

There was a need for a system that could reliably detect these liners, seamlessly integrating with robotic systems for liner removal or addition, depending on the task.

Solution

In response to the challenge, our team of computer vision scientists developed a specialized computer vision system designed to identify and locate pallet liners with pinpoint accuracy.

The system employs sophisticated imaging algorithms that analyze each layer on a pallet, pinpointing the exact location and orientation of liners.

Once identified, the information is relayed to the industrial robots, which then perform the necessary action—either removing the liner during depalletizing or placing a new liner during palletizing.

Technology

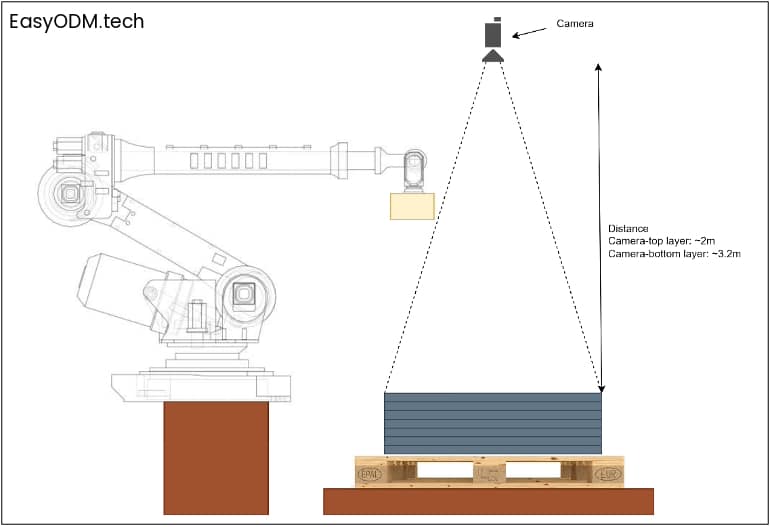

The system utilizes a high-resolution area/matrix camera strategically positioned to capture a top-down view of the pallets.

The camera is connected to a robust processing unit that runs EasyODM machine vision software, equipped with advanced vision algorithms.

This setup ensures that the system can adapt to various pallet patterns and product types, maintaining high operational flexibility.

Integration

The integration process involved close collaboration with the manufacturer to ensure the system was fine-tuned to the specific dimensions and materials of the furniture components and liners.

Integration with existing PLCs and robotic arms was smooth, thanks to EasyODM.tech’s versatile software platform.

The system underwent extensive testing, during which it successfully identified and processed liners across thousands of pallet layers with near-perfect accuracy.

Results

After implementing the EasyODM machine vision system, the manufacturer experienced noticeable improvements in their palletizing and depalletizing operations:

- The handling of pallet liners became an automated process, significantly reducing the manual labor that was previously required.

- The speed of operations improved due to the elimination of the manual handling steps.

- The risk of human error was minimized, leading to a more consistent and reliable packaging process.

- Employee efforts were reallocated to more critical tasks, optimizing the use of human resources.

Conclusion

EasyODM computer vision system has set a new standard for palletizing and depalletizing operations.

By automating the detection and handling of pallet liners, the system has not only improved operational efficiency but has also allowed for more strategic allocation of human resources.

The case of EasyODM.tech illustrates the transformative potential of computer vision in industrial automation.

Want Flawless Product Quality?

Book a free strategy call to see how AI-powered inspection can streamline your production.

Gediminas Mickus

Business Development Manager