Our client, a leading manufacturer in the medical device industry, is renowned for their commitment to delivering high-quality products to the healthcare sector.

With a reputation for innovation and excellence, the client’s products are widely used in medical facilities around the world.

Their dedication to providing reliable and safe medical devices has made them a trusted partner in the industry.

Project Objective

The primary objective of this project was to improve quality control during the final assembly phase of medical devices.

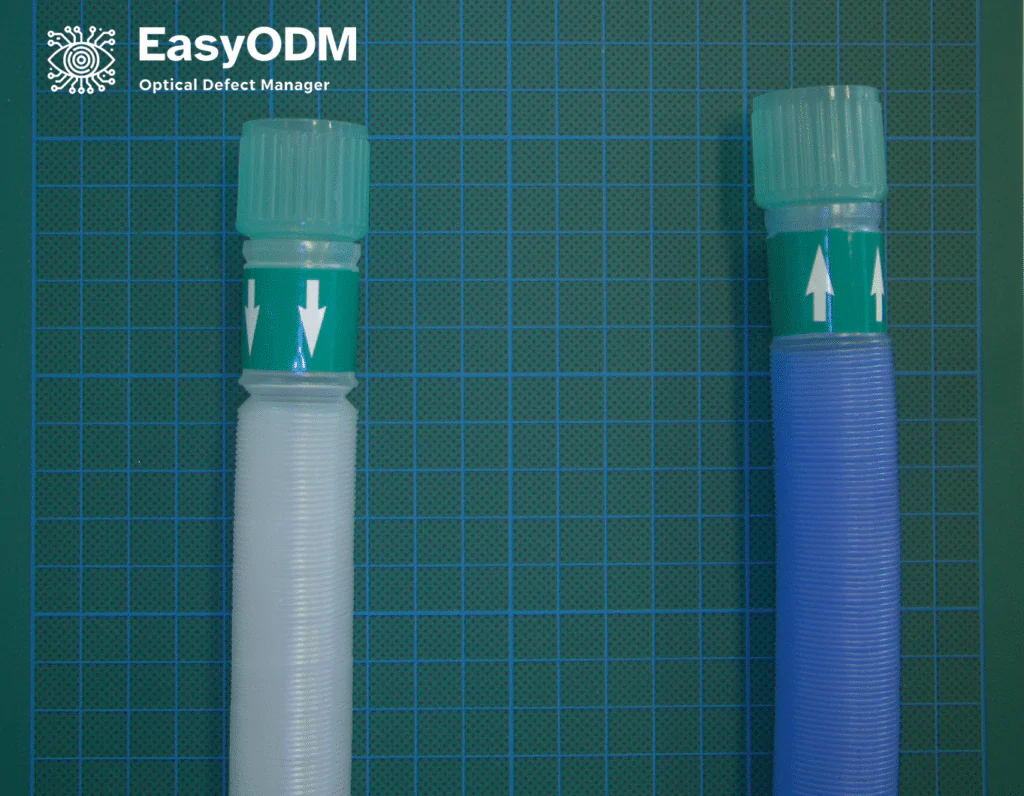

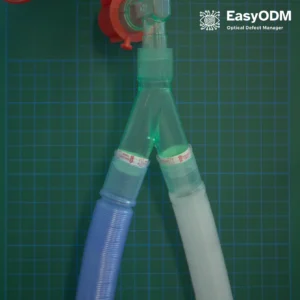

Specifically, the client aimed to detect assembly errors related to directional labels and ensure the correct use of plastic tube color in their products, with the assistance of EasyODM’s advanced machine vision software.

Project Overview

Our client, recognized the critical need to enhance quality control during the final assembly phase of their products.

The primary objectives of this project were to identify assembly errors associated with directional labels and to ensure the accurate use of tube color in the assembly process, utilizing EasyODM’s cutting-edge technology.

Project Requirements for Quality Control

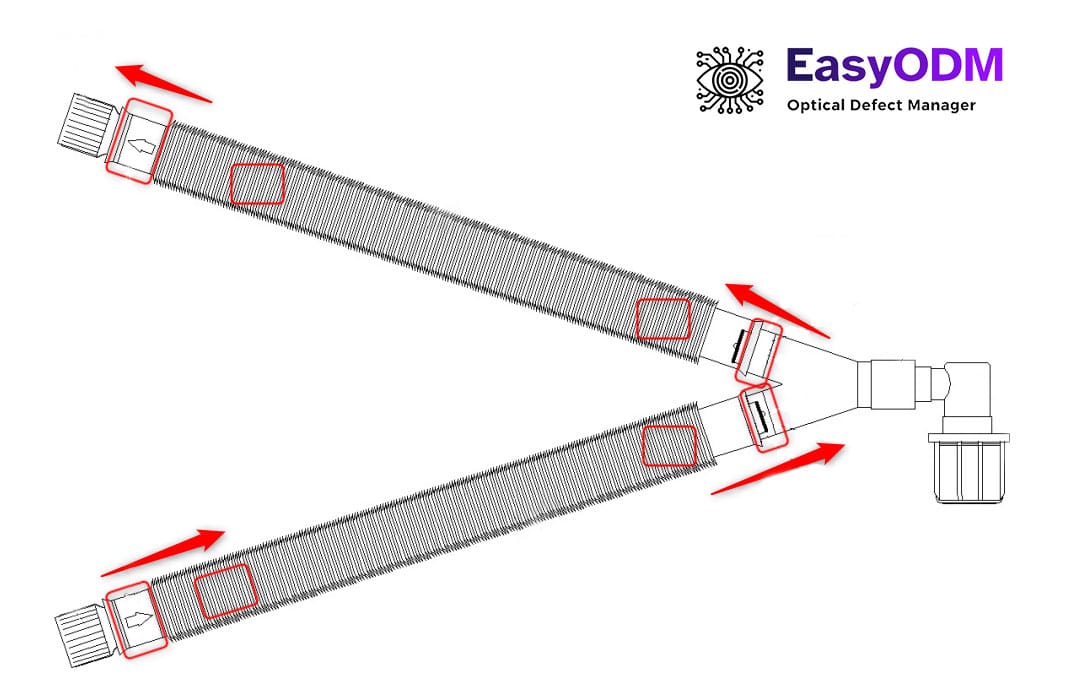

- Develop a comprehensive system to verify the presence and orientation of directional labels in two designated locations using EasyODM’s machine vision capabilities.

- Implement a system capable of accurately confirming the correctness of tube color used in assembly with EasyODM’s image data analysis.

- Ensure the system provides immediate warnings (auditory and/or visual signals) in case of discrepancies or errors, facilitated by EasyODM’s real-time defect detection.

- Prevent the assembly of products with incorrectly affixed directional labels using EasyODM’s unbiased and objective inspection capabilities.

System Implementation

EasyODM’s powerful machine vision software played a central role in the successful implementation of the quality control system:

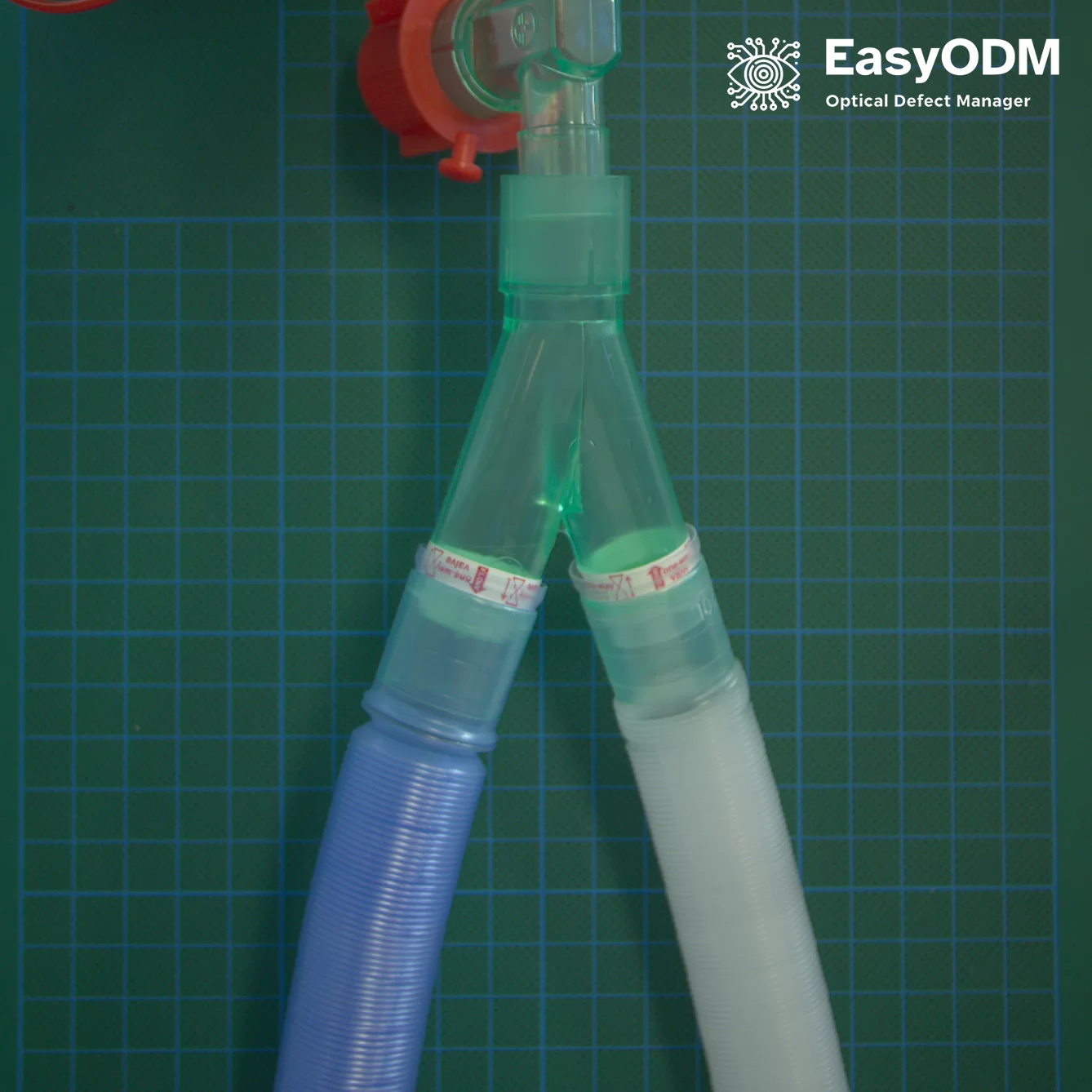

- The solution involved the installation of industrial cameras at the location where final product testing is conducted, ensuring a stationary environment for detection, with EasyODM as the software backbone.

- Two cameras were strategically placed, and EasyODM was trained to analyze the images captured by these cameras, confirming correct directional labels and tube color usage.

- Measures were taken to secure the area where plastic tubes are joined, guaranteeing visibility and minimizing the potential for errors with EasyODM’s consistent performance.

Results and Benefits

The collaboration with EasyODM’s state-of-the-art machine vision software has yielded significant benefits for the client:

- Enhanced Product Quality: Errors related to directional labels and tube color have been virtually eliminated, ensuring consistent product quality with EasyODM’s objective inspection results.

- Improved Safety: Ensuring proper airflow direction is crucial for patient safety, and EasyODM prevents critical assembly errors, contributing to operational safety.

- Efficiency: EasyODM’s automated system provides real-time alerts, allowing for immediate corrective action, reducing downtime, and preventing the assembly of faulty products.

- Cost Savings: By preventing defects, the client has saved on costly product recalls and rework.

Conclusion

By leveraging EasyODM’s powerful machine vision software, the client has successfully elevated the quality and safety standards of their medical devices during the final assembly phase.

The strategic placement of cameras and the implementation of comprehensive checks, supported by EasyODM, have not only ensured accurate directional labels and tube color but have also contributed to cost savings and enhanced operational efficiency.

This case study demonstrates EasyODM’s commitment to delivering cutting-edge technology solutions and its role as a trusted partner in improving quality control processes in the healthcare industry for our valued client.